For furnaces operating above 1200°C, the primary heating elements used are silicon carbide (SiC) and molybdenum disilicide (MoSi2). For even more extreme temperatures, specialized elements like pure molybdenum and graphite are required, though they demand specific atmospheric conditions to function.

The choice of a high-temperature heating element is not just about reaching a peak temperature; it is a critical decision based on the required operating atmosphere, the element's lifespan at temperature, and its chemical compatibility with your process.

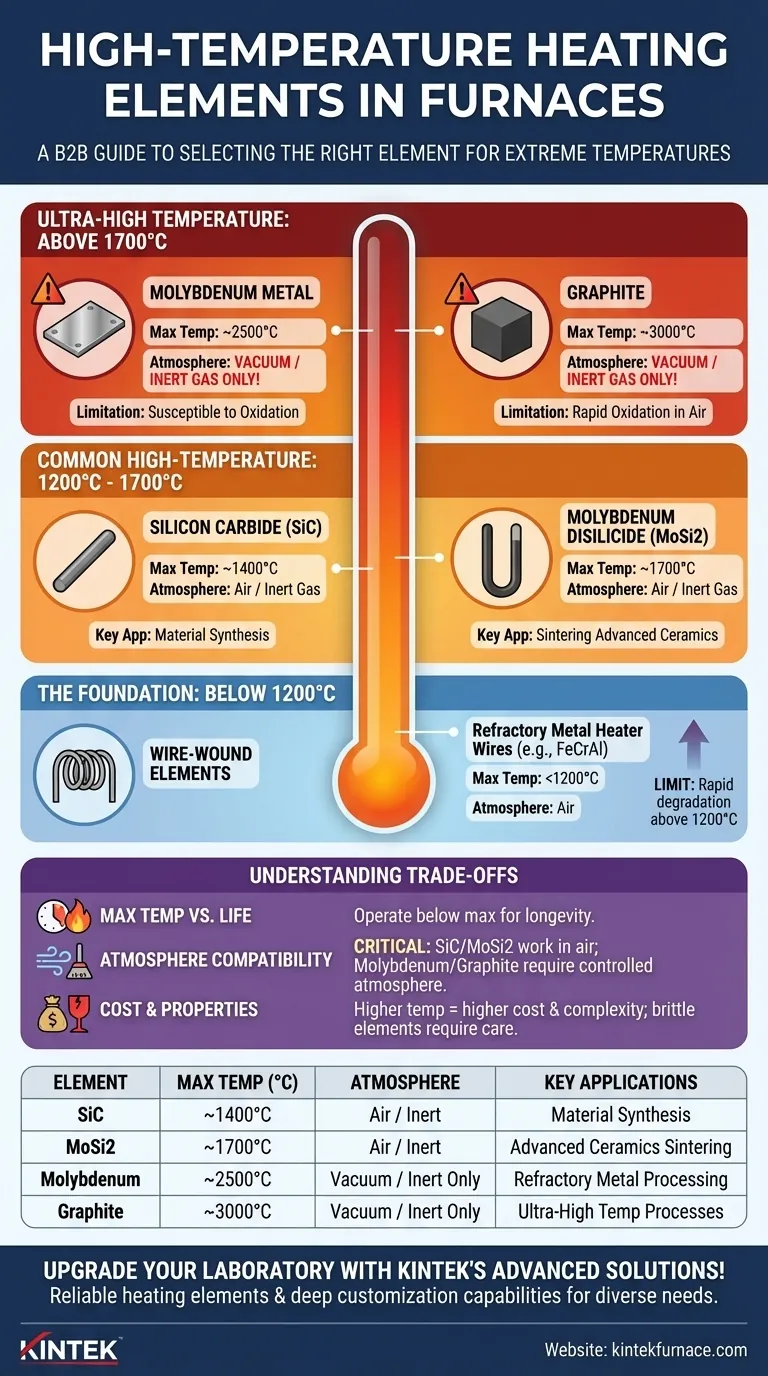

The Foundation: Standard vs. High-Temperature Heating

To understand high-temperature elements, it's useful to know the baseline. Many common furnaces are limited to a maximum temperature for a specific reason.

Below 1200°C: Wire-Wound Elements

Furnaces designed for 1200°C or less typically use refractory metal heater wires. These elements, often made of iron-chromium-aluminum alloys, are embedded into the furnace's insulated walls.

This design maximizes thermal uniformity and internal space but has a clear temperature ceiling. Pushing these elements past their limit leads to rapid degradation and failure.

Stepping Up: Common High-Temperature Elements

When processes require temperatures between 1200°C and 1700°C, a different class of ceramic-based elements becomes necessary. These are the workhorses of modern high-temperature applications.

Silicon Carbide (SiC) Elements (Up to ~1400°C)

Silicon carbide is a robust and reliable choice for applications that need to exceed the limits of wire elements. They are often suspended as rods within the furnace chamber.

SiC elements are known for their durability and resistance to wear, making them suitable for a wide range of material synthesis and processing tasks.

Molybdenum Disilicide (MoSi2) Elements (Up to ~1700°C)

For the next tier of temperature, molybdenum disilicide is the industry standard. These elements can operate at significantly higher temperatures than SiC.

Often called "silicon molybdenum" rods, MoSi2 elements are essential for processes like sintering advanced ceramics that demand temperatures approaching 1700°C. They generate immense heat and offer excellent resistance to corrosion in many environments.

Pushing the Limits: Ultra-High Temperature Options

Reaching temperatures above 1700°C requires moving beyond ceramic composites to pure elements that have extremely high melting points. However, these elements come with a critical constraint.

Molybdenum Metal Elements (Up to ~2500°C)

Pure molybdenum heaters can reach temperatures far beyond MoSi2. They are used in highly specialized furnaces for refractory metal processing and other demanding applications.

Their primary limitation is a severe susceptibility to oxidation. Molybdenum elements must be operated in a vacuum or a pure, inert gas atmosphere (like argon) to prevent them from burning up instantly.

Graphite Elements (Up to ~3000°C)

For the most extreme thermal processes, graphite is the ultimate choice for resistance heating, capable of reaching temperatures of 3,000°C.

Like molybdenum, graphite will rapidly oxidize and disintegrate if exposed to oxygen at high temperatures. Therefore, graphite furnaces are always designed to operate under a high vacuum or in a controlled inert gas environment.

Understanding the Trade-offs

Selecting an element is a balancing act. The highest temperature is not always the best choice, as it introduces complexity and operational constraints.

Maximum Temperature vs. Operating Life

Every heating element has a maximum temperature, but running it constantly at that peak will drastically shorten its lifespan. For longevity, furnaces are typically operated a couple of hundred degrees below the element's absolute maximum.

Atmosphere Compatibility is Critical

This is the most important trade-off. SiC and MoSi2 can often operate in an air atmosphere, making them versatile and easier to use.

In contrast, molybdenum and graphite absolutely require a controlled, oxygen-free atmosphere. This adds significant cost and complexity to the furnace design, involving vacuum pumps, gas delivery systems, and sophisticated controls.

Cost and Physical Properties

High-temperature elements are more expensive than standard wire. They can also be brittle, especially at room temperature, requiring careful handling during installation and maintenance.

Making the Right Choice for Your Application

Your final decision must be guided by the specific requirements of your process, not just a desire for the highest temperature.

- If your primary focus is routine heating up to 1400°C: Silicon Carbide (SiC) provides a reliable and cost-effective solution that works well in air.

- If your primary focus is high-temperature sintering in air (up to 1700°C): Molybdenum Disilicide (MoSi2) is the definitive choice for its high thermal capability in an oxygen environment.

- If your primary focus is ultra-high temperatures above 1800°C: Graphite is the standard, but you must be prepared to operate within a vacuum or inert gas atmosphere.

Choosing the correct element ensures your equipment is not only capable but also reliable and cost-effective for its intended task.

Summary Table:

| Element Type | Max Temperature (°C) | Atmosphere Requirements | Key Applications |

|---|---|---|---|

| Silicon Carbide (SiC) | ~1400°C | Air or inert gases | Material synthesis, general high-temp processing |

| Molybdenum Disilicide (MoSi2) | ~1700°C | Air or inert gases | Sintering advanced ceramics |

| Molybdenum | ~2500°C | Vacuum or inert gas only | Refractory metal processing |

| Graphite | ~3000°C | Vacuum or inert gas only | Ultra-high temperature processes |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable heating elements and systems tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your high-temperature processes with durable, efficient, and custom-designed furnaces!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness