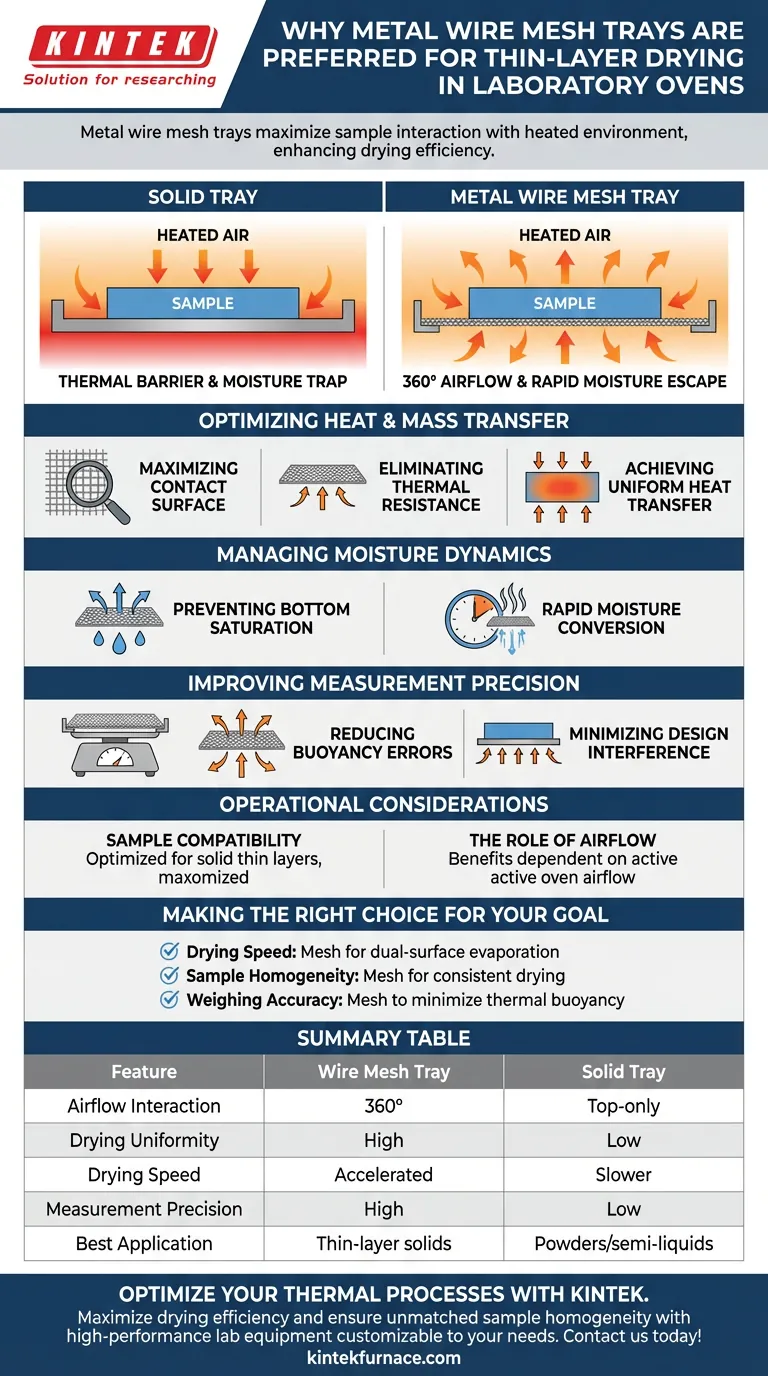

Metal wire mesh trays are the superior choice for thin-layer drying because they maximize the interaction between the sample and the heated environment. By replacing a solid surface with an open grid, these trays allow heated airflow to penetrate the material layer from both above and below, significantly enhancing the efficiency of the process.

The open structural design of wire mesh eliminates the thermal barriers found in solid trays. This ensures uniform heat transfer, prevents moisture accumulation at the base of the sample, and improves weighing accuracy by mitigating air buoyancy effects.

Optimizing Heat and Mass Transfer

Maximizing Contact Surface

The primary advantage of a wire mesh tray is the maximization of contact area. In a standard drying process, the goal is to expose as much of the sample as possible to the heated air.

Eliminating Thermal Resistance

Solid trays act as a barrier, heating the sample only from the top and sides while insulating the bottom. Mesh trays allow airflow to reach the underside of the sample, effectively eliminating thermal resistance at the material's base.

Achieving Uniform Heat Transfer

Because the heated air surrounds the sample completely, heat transfer occurs evenly across the entire material. This uniformity is critical for consistent results, ensuring that the top of the sample does not dry out while the bottom remains damp.

Managing Moisture Dynamics

Preventing Bottom Saturation

When drying materials on solid surfaces, moisture often migrates downward and becomes trapped between the sample and the tray. The open structure of the mesh prevents this moisture accumulation, allowing humidity to escape freely from the bottom.

Rapid Moisture Conversion

The combination of improved airflow and the elimination of trapped moisture leads to rapid moisture conversion. This significantly reduces the total time required to achieve the desired dry state for the thin layer.

Improving Measurement Precision

Reducing Buoyancy Errors

In laboratory settings involving precise weighing during heating, hot air rising can create a buoyancy effect that skews measurements. Solid trays can act like a "sail" for this rising air.

Minimizing Design Interference

The wire mesh structure is permeable, allowing rising air to pass through it rather than pushing against it. This helps reduce measurement errors caused by air buoyancy, ensuring that the recorded weight reflects the sample's mass, not the airflow forces.

Operational Considerations

Understanding Sample Compatibility

While wire mesh offers superior drying dynamics, it is specifically optimized for thin-layer drying of solid materials. It relies on the structural integrity of the sample to sit atop the mesh without falling through the apertures.

The Role of Airflow

The benefits of these trays are entirely dependent on the oven's ability to circulate air. Without active airflow (convection), the advantage of the "bottom-up" exposure is diminished, though the reduction in conductive thermal resistance remains a benefit.

Making the Right Choice for Your Goal

To maximize the efficiency of your laboratory drying process, align your equipment choice with your specific objectives:

- If your primary focus is Drying Speed: Utilize mesh trays to allow airflow from both above and below, doubling the active drying surface.

- If your primary focus is Sample Homogeneity: Choose mesh to ensure the bottom of the layer dries at the same rate as the top, preventing gradients.

- If your primary focus is Weighing Accuracy: Rely on the open mesh structure to minimize the influence of thermal buoyancy on your scale readings.

By switching to metal wire mesh, you transform the tray from a passive holder into an active component of the drying system.

Summary Table:

| Feature | Wire Mesh Tray | Solid Tray |

|---|---|---|

| Airflow Interaction | 360° penetration (top & bottom) | Top-only exposure |

| Drying Uniformity | High - prevents bottom saturation | Low - risks moisture gradients |

| Drying Speed | Accelerated via dual-surface evaporation | Slower due to base insulation |

| Measurement Precision | High - minimizes buoyancy effects | Low - solid base creates air lift |

| Best Application | Thin-layer solid materials | Powders or semi-liquids |

Optimize Your Thermal Processes with KINTEK

Maximize your laboratory drying efficiency and ensure unmatched sample homogeneity with high-performance solutions from KINTEK. Backed by expert R&D and precision manufacturing, we provide high-temperature lab equipment—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to your unique drying and heat treatment needs.

Don’t let inefficient tray designs or inconsistent airflow compromise your research results. Contact us today to find the perfect thermal solution for your lab!

Visual Guide

References

- Effects of Drying Temperatures on Nutritional and Phytochemical Properties of Gongronema Latifolium Leaves. DOI: 10.63958/azojete/2025/21/2/001

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the purpose of waveguide-to-coax adapters? Key Roles in High-Temperature Measurement Chains

- What is the specific utility of crucibles in high-temperature lab applications? Precision & Thermal Integrity

- How does the circulating water multifunctional vacuum pump create a vacuum? Discover Its Oil-Free Mechanism

- What is the technical objective of using vacuum-sealed quartz capsules for Co-Ti-V alloy homogenization? Safeguard Chemical Integrity

- Why is a laboratory pellet press used to compress powders? Optimize Conductivity for Flash Joule Heating

- How do stainless steel furnace chambers and insulating linings contribute to thermal design? Boost Energy Efficiency

- Why is vacuum sealing in high-purity quartz tubes necessary for the synthesis of FexTaSe2? Master Crystal Growth

- Why is the use of high-vacuum pump groups critical for photothermal catalytic chamber pre-treatment?