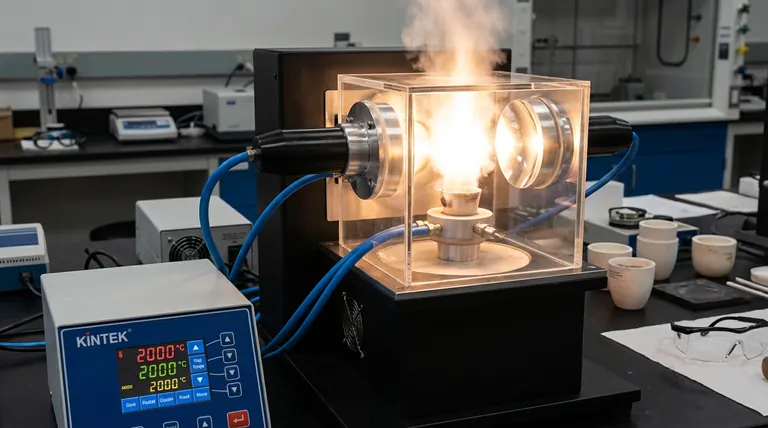

An arc-imaging furnace functions as a specialized high-energy thermal source primarily used for the rapid discovery of specific material phases. In the context of NaMgPO4:Eu phosphors, its role is to subject reactants to immediate, extreme thermal shock, raising temperatures to 2000 °C almost instantaneously to facilitate unique synthesis conditions.

The arc-imaging furnace is a tool for material discovery rather than high-purity production. By combining ultra-high temperatures with rapid cooling, it successfully isolates the olivine phase of NaMgPO4, though this aggressive process inherently results in samples containing multiple impurities.

The Mechanics of High-Energy Synthesis

Reaching Extreme Temperatures

The primary advantage of the arc-imaging furnace is its ability to generate extremely high instantaneous energy.

Unlike conventional furnaces that ramp up heat slowly, this apparatus allows the reactants to reach ultra-high temperatures of roughly 2000 °C in a very short timeframe.

The Melt-Quench Process

The synthesis process is not solely defined by the heating phase but also by how that heat is removed.

Following the rapid heating, the material undergoes a water-cooling rapid quenching process. This sudden drop in temperature is essential for "freezing" specific crystal structures that might destabilize during slow cooling.

Enabling Phase Discovery

Isolating the Olivine Phase

The extreme conditions created by the arc-imaging furnace are critical for the discovery of the olivine phase of NaMgPO4.

Standard synthesis methods may not provide the necessary thermodynamic conditions to form this specific crystal structure.

Handling Silicate-Deficiency

This high-energy method is particularly robust when dealing with non-standard compositions.

Specifically, it allows for the synthesis of the olivine phase even when the material is in a silicate-deficient state, expanding the range of potential phosphor compositions researchers can explore.

Understanding the Trade-offs

The Challenge of Impurity Phases

While the arc-imaging furnace is excellent for discovering new phases, it lacks the precision required for high-purity synthesis.

Samples produced via this method typically contain multiple impurity phases. The aggressive nature of the heating and quenching prevents the equilibrium required to form a single, pure phase, making this tool better suited for initial exploration than final product manufacturing.

Making the Right Choice for Your Research

If you are evaluating synthesis methods for NaMgPO4:Eu phosphors, consider your specific end goal:

- If your primary focus is phase discovery: Use the arc-imaging furnace to access high-temperature phases like the olivine structure that are difficult to achieve with standard heating.

- If your primary focus is compositional purity: Be aware that this method will likely require post-processing or alternative synthesis routes to eliminate the secondary impurity phases generated during rapid quenching.

Use the arc-imaging furnace to unlock the material's existence, but anticipate the need for refinement to achieve a pure phosphor.

Summary Table:

| Feature | Arc-Imaging Furnace Role | Impact on NaMgPO4:Eu |

|---|---|---|

| Temperature | Instantaneous reach to ~2000 °C | Facilitates unique high-energy synthesis conditions |

| Cooling | Water-cooled rapid quenching | "Freezes" the specific olivine crystal structure |

| Phase Isolation | High-energy thermal shock | Enables discovery of silicate-deficient phases |

| Purity Level | Low (Multiple impurity phases) | Best suited for exploration rather than mass production |

Elevate Your Material Discovery with KINTEK

Transition from initial phase discovery to high-purity production with precision equipment tailored for advanced materials research. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temp furnaces—all fully customizable to meet your unique phosphor synthesis requirements.

Ready to achieve the perfect balance of temperature control and material purity? Contact our technical experts today to find the ideal thermal solution for your laboratory.

References

- Jianwei Qiao, Lei Wang. Compositional engineering of phase-stable and highly efficient deep-red emitting phosphor for advanced plant lighting systems. DOI: 10.1038/s41377-024-01679-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does temperature control precision affect c-BAs crystal growth? Ensure Lattice Integrity in Two-Week Cycles

- Why are a blast drying oven and a freeze dryer both necessary for GO nanofibers? Essential Drying Synergy

- What are the drawbacks of cold compacting and sintering? Higher Porosity and Weaker Mechanical Properties

- What is the role of a high-energy ball mill in NiWO4/GO preparation? Master High-Performance Composite Synthesis

- What reaction conditions are provided by stirring and heating equipment? Optimize Non-Aqueous Sol-Gel Synthesis

- Why is a drying oven preferred for the post-treatment cleaning of activated carbon? Protect Your Material's Structure

- Why is precise temperature control below 1700°C required for beta-SiC? Master Your Cubic Silicon Carbide Synthesis

- What is the function of an inert gas supply system in black liquor pyrolysis? Achieve Precise Atmospheric Control