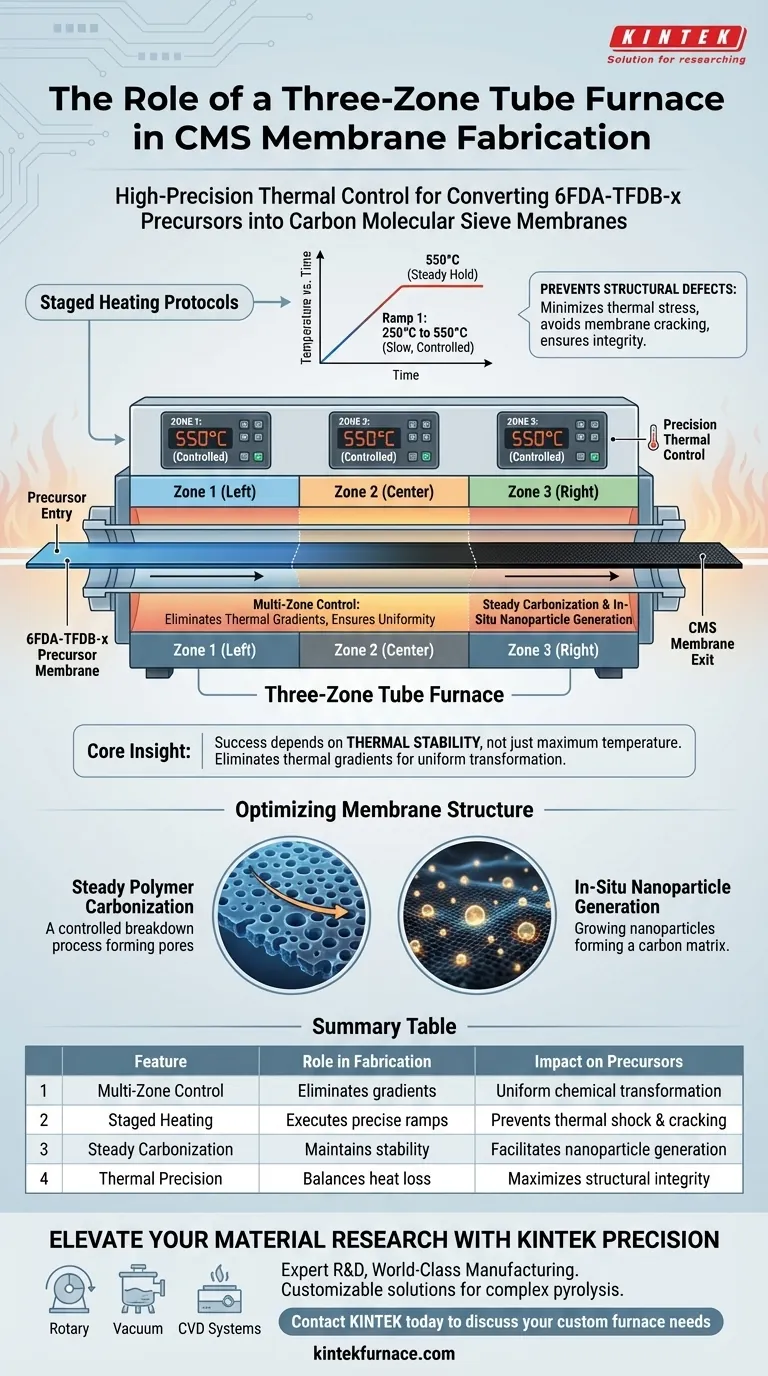

A three-zone tube furnace serves as a high-precision thermal control system essential for converting 6FDA-TFDB-x precursors into Carbon Molecular Sieve (CMS) membranes. By maintaining strict temperature uniformity and executing complex staged heating protocols, this equipment facilitates steady carbonization and in-situ nanoparticle generation while preventing structural failures like cracking.

Core Insight: The success of CMS membrane fabrication depends less on maximum temperature and more on thermal stability. The three-zone furnace is critical because it eliminates thermal gradients that cause stress, ensuring the delicate polymer structure survives the transition to carbon.

Ensuring Thermal Field Uniformity

The Mechanism of Multi-Zone Control

The defining characteristic of a three-zone furnace is its ability to divide the heating chamber into three individually controlled segments. Unlike single-zone furnaces, which may suffer from temperature drop-offs near the ends, this configuration actively balances heat input across the entire tube length.

Consistency for Pyrolysis

For 6FDA-TFDB-x precursors, the pyrolysis environment must be identical across the entire membrane surface. The multi-zone system creates a high-uniformity temperature field, ensuring that every part of the precursor undergoes the same chemical transformation at temperatures of 550°C or higher.

Managing Pyrolysis Dynamics

Precise Staged Heating

Converting polymer precursors is a delicate process requiring specific ramp rates. The furnace enables precise, staged heating controls, particularly in the critical window between 250°C and 550°C. This allows the material to evolve chemically without undergoing thermal shock.

Preventing Structural Defects

Membrane cracking is a common failure mode caused by thermal stress during rapid or uneven heating. By strictly controlling the heating rate and maintaining uniformity, the furnace minimizes these stresses. This protection allows the membrane to remain intact during the significant volume changes associated with carbonization.

Optimizing Membrane Structure

Steady Polymer Carbonization

The stability provided by the furnace ensures that carbonization proceeds at a steady, predictable pace. This controlled breakdown is necessary to form the specific pore structures required for effective molecular sieving.

In-Situ Nanoparticle Generation

Beyond preventing defects, the thermal environment plays an active role in material synthesis. The precise thermal treatment facilitates the in-situ generation of nanoparticles within the matrix, a key factor in the performance of the final CMS membrane.

Understanding the Trade-offs

Calibration Complexity

While a three-zone furnace offers superior control, it introduces operational complexity. To achieve a perfectly flat temperature profile, the three zones must be carefully calibrated to compensate for heat loss at the tube ends.

Throughput vs. Precision

The rigorous staged heating protocols required for 6FDA-TFDB-x precursors often necessitate longer processing times compared to rapid thermal treatments. This is a necessary trade-off: speed is sacrificed to ensure the structural integrity and chemical uniformity of the final membrane.

Making the Right Choice for Your Goal

When configuring your thermal treatment process for CMS membranes, consider the following priorities:

- If your primary focus is preventing membrane cracking: Prioritize the staged heating control capabilities of the furnace to ensure a slow, steady ramp from 250°C to 550°C.

- If your primary focus is consistent pore structure: Rely on the multi-zone temperature control to eliminate gradients and ensure every millimeter of the sample experiences the exact same thermal history.

Mastering the thermal profile of the three-zone furnace is the decisive factor in producing defect-free, high-performance carbon molecular sieve membranes.

Summary Table:

| Feature | Role in CMS Membrane Fabrication | Impact on 6FDA-TFDB-x Precursors |

|---|---|---|

| Multi-Zone Control | Eliminates thermal gradients across the tube | Ensures uniform chemical transformation and pore structure |

| Staged Heating | Executes precise ramp rates (250°C to 550°C) | Prevents thermal shock and membrane cracking |

| Steady Carbonization | Maintains consistent thermal field stability | Facilitates in-situ nanoparticle generation |

| Thermal Precision | Balances heat loss at tube ends | Maximizes structural integrity of the delicate polymer matrix |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect pore structure in CMS membranes requires more than just heat—it requires absolute thermal control. KINTEK provides industry-leading Three-Zone Tube Furnaces, alongside our specialized Rotary, Vacuum, and CVD systems, specifically engineered for complex pyrolysis and carbonization workflows.

Backed by expert R&D and world-class manufacturing, our systems are fully customizable to meet the rigorous staged heating demands of 6FDA-TFDB-x precursors and other advanced polymers. Ensure defect-free results and superior molecular sieving performance—Contact KINTEK today to discuss your custom furnace needs.

Visual Guide

References

- Xiuling Chen, Nanwen Li. Atomically distributed Al-F3 nanoparticles towards precisely modulating pore size of carbon membranes for gas separation. DOI: 10.1038/s41467-024-54275-1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary function of a horizontal tube furnace in simulating the oxidation behavior of hot-rolled steel?

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a Tube Furnace play in HDS catalyst de-oiling? Unlock Efficient Pyrolysis Recovery

- Why is a tube furnace preferred for NRBBO:Eu2+ synthesis? Achieve Precise Atmosphere Control for Phosphors

- What happens to quartz tubes in a tube furnace at temperatures above 1000°C? Understanding Devitrification and Material Limits

- What are the technical functions of an industrial tube furnace for ZIF-8 carbonization? Master Precise Pyrolysis

- What advantages does a fluidized bed vertical tube furnace offer in terms of operation? Unlock Superior Heat Transfer and Uniformity

- What is the role of a horizontal tube furnace in the plastic waste pyrolysis process? Driving Polymer Decomposition