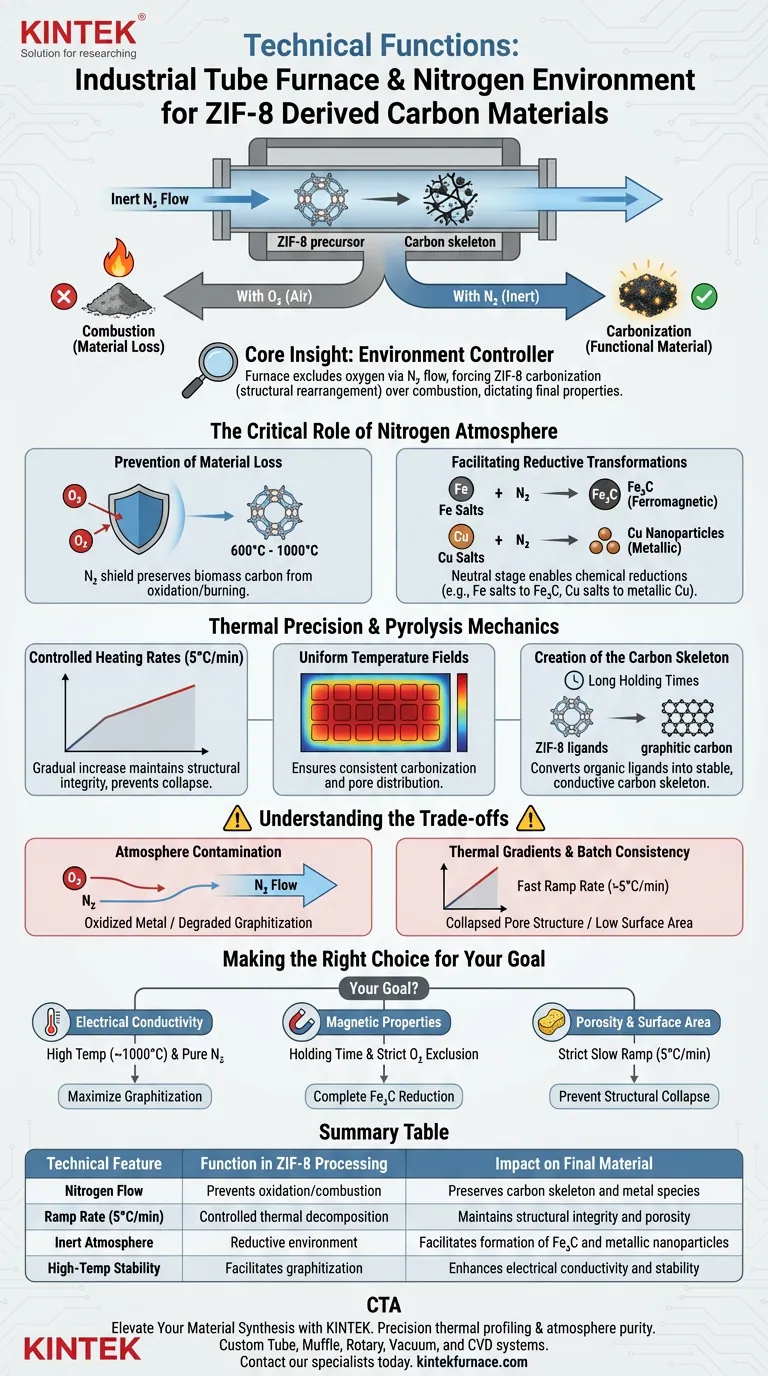

The technical function of an industrial tube furnace in this context is to provide a strictly regulated thermal reactor that decouples high temperatures from oxidation. By maintaining a continuous flow of inert nitrogen gas, the system allows for the pyrolysis of ZIF-8 precursors, enabling the precise conversion of organic ligands into conductive carbon skeletons and the transformation of metal salts into active species without combustion.

Core Insight: The tube furnace is not simply a heating element; it is an environment controller. By excluding oxygen via nitrogen flow, it forces the ZIF-8 material to undergo carbonization (structural rearrangement) rather than combustion (burning), directly dictating the final material's conductivity, porosity, and magnetic properties.

The Critical Role of the Nitrogen Atmosphere

Prevention of Material Loss

At the elevated temperatures required for this process (often between 600°C and 1000°C), carbon-based materials are highly susceptible to oxidation.

Without a nitrogen shield, the organic components of ZIF-8 would react with oxygen and burn away completely. The inert nitrogen atmosphere ensures that the biomass carbon is preserved and restructured rather than consumed.

Facilitating Reductive Transformations

The nitrogen environment creates a neutral stage that allows specific chemical reductions to occur.

As referenced in your primary data, this atmosphere enables impregnated iron salts to transform into ferromagnetic iron carbide (Fe3C) species. Similarly, it allows for the reduction of other metals, such as converting copper salts into metallic copper nanoparticles, which would otherwise form oxides in standard air.

Thermal Precision and Pyrolysis Mechanics

Controlled Heating Rates

The tube furnace allows for programmable ramp rates, such as the specific 5 °C per minute rate mentioned in technical specifications.

This gradual increase is critical for maintaining the structural integrity of the material. A controlled rate prevents the rapid collapse of the framework, allowing organic ligands to decompose systematically into a nitrogen-doped carbon substrate.

Uniform Temperature Fields

For industrial applications, consistency across the material batch is paramount.

The tube furnace provides a uniform temperature field that ensures consistent carbonization throughout the sample. This uniformity directly impacts the final adsorbent's porosity and the even distribution of chemical active sites.

Creation of the Carbon Skeleton

The defining function of the furnace is to facilitate long-duration thermal treatment, known as holding times.

During this phase, the ZIF-8 organic ligands are converted into a chemically stable and electrically conductive carbon skeleton. This process, often involving graphitization at higher temperatures (e.g., 1000°C), locks in the specific pore structures derived from the original ZIF framework.

Understanding the Trade-offs

The Risk of Atmosphere Contamination

The process relies entirely on the purity of the nitrogen flow.

Even trace amounts of oxygen entering the tube can degrade the graphitization process or oxidize the metal active sites (e.g., turning Fe3C into iron oxide), rendering the material less conductive or non-magnetic.

Thermal Gradients and Batch Consistency

While tube furnaces offer precise control, ramping temperatures too quickly to save time is a common pitfall.

Accelerating the heating rate beyond the recommended 5 °C/min can lead to the collapse of the pore structure before the carbon skeleton hardens, resulting in a material with low surface area and poor catalytic performance.

Making the Right Choice for Your Goal

To optimize your ZIF-8 derived materials, align your furnace settings with your specific end-goal:

- If your primary focus is Electrical Conductivity: Prioritize higher temperatures (around 1000°C) and ensure absolute nitrogen purity to maximize graphitization of the carbon skeleton.

- If your primary focus is Magnetic Properties: Focus on the holding time and the strict exclusion of oxygen to ensure the complete reduction of iron salts into ferromagnetic iron carbide (Fe3C).

- If your primary focus is Porosity and Surface Area: Adhere strictly to slow heating rates (e.g., 5 °C/min) to prevent structural collapse during ligand decomposition.

Precision in the thermal profile and atmosphere purity is the difference between creating high-performance functional carbon and creating simple ash.

Summary Table:

| Technical Feature | Function in ZIF-8 Processing | Impact on Final Material |

|---|---|---|

| Nitrogen Flow | Prevents oxidation/combustion | Preserves carbon skeleton and metal species |

| Ramp Rate (5°C/min) | Controlled thermal decomposition | Maintains structural integrity and porosity |

| Inert Atmosphere | Reductive environment | Facilitates formation of Fe3C and metallic nanoparticles |

| High-Temp Stability | Facilitates graphitization | Enhances electrical conductivity and stability |

Elevate Your Material Synthesis with KINTEK

Precision in thermal profiling and atmosphere purity is the difference between high-performance functional carbon and simple ash. Backed by expert R&D and manufacturing, KINTEK offers specialized Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of ZIF-8 derivation and advanced carbonization.

Our lab high-temp furnaces provide the uniform temperature fields and airtight nitrogen control required to ensure your materials achieve peak conductivity, porosity, and magnetic properties.

Ready to optimize your research or production? Contact our specialists today to find your custom furnace solution.

Visual Guide

References

- Yongheng Shi, Wei Du. Preparation of Ordered Macroporous ZIF-8-Derived Magnetic Carbon Materials and Its Application for Lipase Immobilization. DOI: 10.3390/catal14010055

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the function of a laboratory tube furnace in Ti-5Al-4W-2Fe alloy forging? Enhance Thermoplasticity & Purity

- What is the purpose of using a tube furnace for a second calcination at 750°C? Mastering Biochar Activation

- Why is high-purity argon purging necessary for a tube furnace prior to Sb2Se3 synthesis? Ensure Pure Nanowire Growth

- How does a laboratory horizontal tube furnace facilitate the sintering of powder metallurgy structural steel?

- What role does a high-temperature tube furnace play in biomass carbon skeletons? Master Structural Integrity.

- How does the gas control system of a tube furnace contribute to the transformation of Ni-MOF into NiO/Ni@C?

- Why is the temperature control accuracy of a high-purity tube furnace critical? Mastering PCNF Carbonization

- How does a tube furnace facilitate the annealing process for Antimony-doped ZnSe and PbSe thin films? Key Performance Tips