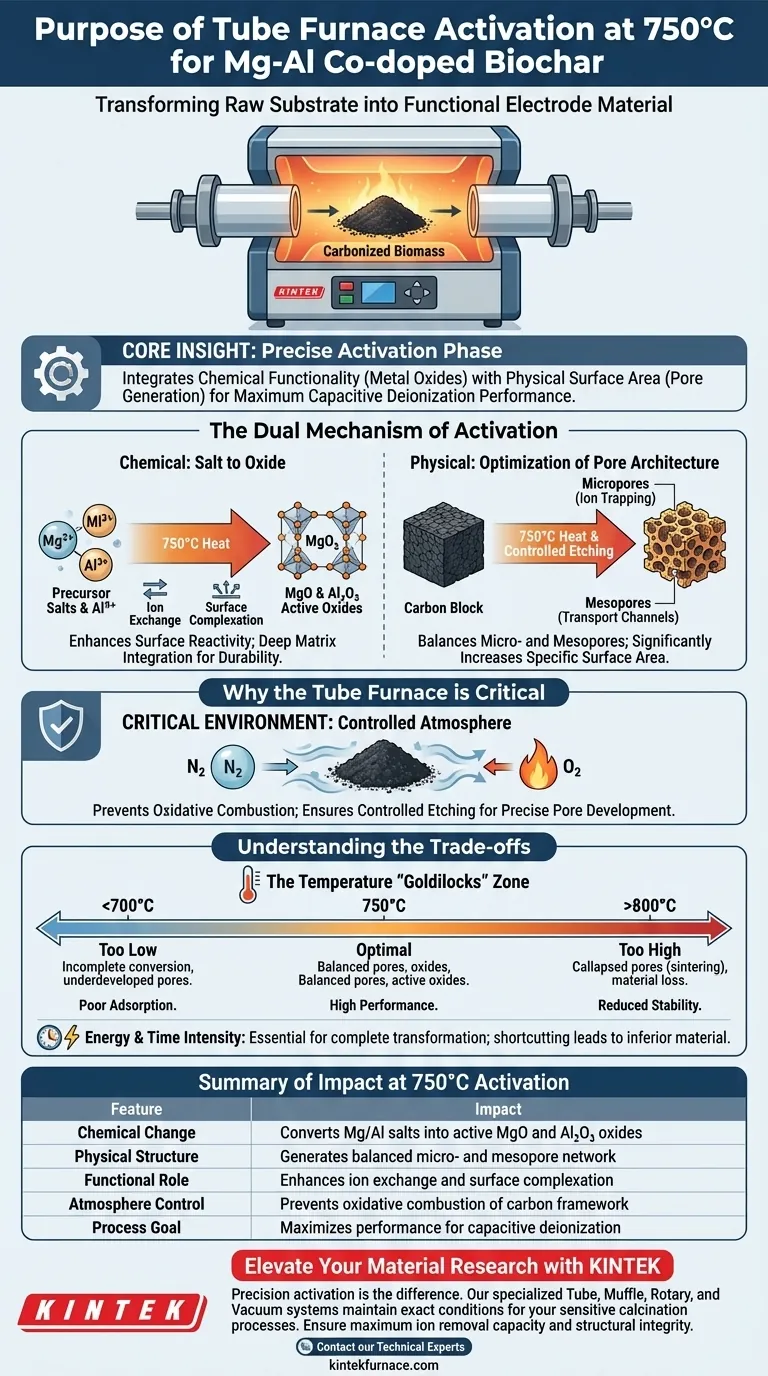

The primary purpose of this second calcination is to physically and chemically activate the biochar, transforming it from a raw substrate into a functional electrode material. At 750°C, the tube furnace facilitates the conversion of doped metal salts into active oxides (MgO and Al2O3) and etches the carbon framework to create a highly porous structure optimized for ion adsorption.

Core Insight: This process is not merely about heating; it is a precise activation phase. It integrates chemical functionality (through metal oxides) with physical surface area (through pore generation) to maximize the material's performance in capacitive deionization.

The Dual Mechanism of Activation

Chemical Transformation: Salt to Oxide

The most critical chemical change occurring at 750°C is the conversion of magnesium and aluminum salts. The high thermal energy drives a reaction that transforms these precursor salts into stable active oxides, specifically MgO and Al2O3.

Enhancing Surface Reactivity

These newly formed oxides are not passive fillers. They provide the biochar with specific chemical capabilities, including ion exchange and surface complexation. This chemical activation allows the material to actively interact with and capture ions, rather than relying solely on physical trapping.

Deep Matrix Integration

The tube furnace ensures the deep integration of these metals into the carbon matrix. Rather than sitting loosely on the surface, the metal species are thermally fused within the carbon structure, ensuring durability and consistent performance during electrochemical applications.

Physical Structuring of the Biochar

Optimization of Pore Architecture

Simultaneous with the chemical changes, the heat treatment remodels the physical structure of the carbon. The process induces the generation of new pores, significantly increasing the specific surface area of the material.

Balancing Micro- and Mesopores

The 750°C activation specifically optimizes the distribution of micropores (tiny pores for trapping small ions) and mesopores (transport channels). This balanced pore structure allows ions to penetrate the material quickly and be stored effectively, which is essential for high-capacity deionization.

Why the Tube Furnace Environment is Critical

Prevention of Oxidative Combustion

While the primary reaction involves oxidation of the salts, the carbon backbone itself must be protected. A tube furnace typically operates under a controlled inert atmosphere (such as nitrogen), which prevents the biochar from burning away (oxidative combustion) at these high temperatures.

Controlled Etching

By excluding external oxygen, the furnace ensures that the carbon framework is etched precisely by the internal activating agents rather than consumed by fire. This controlled environment is what allows for the precise development of the porous structure without destroying the material's yield.

Understanding the Trade-offs

The Temperature "Goldilocks" Zone

Operating at exactly 750°C is a deliberate choice involving distinct trade-offs.

- Too Low (<700°C): The metal salts may not fully decompose into active oxides, and the pore structure may remain underdeveloped, resulting in poor adsorption capacity.

- Too High (>800°C): Excessive heat can cause the pore structure to collapse (sintering) or lead to aggressive etching that reduces the overall material yield and mechanical stability.

Energy and Time Intensity

This secondary calcination is an energy-intensive step. It requires maintaining high temperatures for sustained periods to ensure complete crystal phase transformation and diffusion. Skipping or shortening this step to save energy will result in a material with "blocked" pores and chemically inert surfaces.

Making the Right Choice for Your Goal

If your primary focus is Ion Removal Capacity:

- Ensure the temperature reaches the full 750°C to guarantee the complete conversion of salts into MgO and Al2O3, as these are the active sites for ion exchange.

If your primary focus is Structural Integrity:

- Monitor the atmosphere strictly; any leak of oxygen into the tube furnace at this temperature will incinerate your carbon matrix and destroy the pore structure.

The tube furnace activation is the defining step that converts a simple carbonized biomass into a high-performance electrochemical tool.

Summary Table:

| Feature | Impact at 750°C Activation Phase |

|---|---|

| Chemical Change | Converts Mg/Al salts into active MgO and Al2O3 oxides |

| Physical Structure | Generates a balanced network of micro- and mesopores |

| Functional Role | Enhances ion exchange and surface complexation capabilities |

| Atmosphere Control | Prevents oxidative combustion of the carbon framework |

| Process Goal | Maximizes performance for capacitive deionization |

Elevate Your Material Research with KINTEK

Precision activation is the difference between raw carbon and a high-performance electrode. Backed by expert R&D and manufacturing, KINTEK offers specialized Tube, Muffle, Rotary, and Vacuum systems designed to maintain the exact thermal and atmospheric conditions required for your most sensitive calcination processes.

Whether you are synthesizing Mg-Al co-doped biochar or developing advanced CVD systems, our lab high-temp furnaces are fully customizable to meet your unique research needs. Ensure maximum ion removal capacity and structural integrity for your materials today.

Ready to optimize your activation phase? Contact our technical experts at KINTEK today.

Visual Guide

References

- Geming Wang, Qirui Wu. Exploring a Porous Biochar-Based Capacitive Deionization Device for Phosphogypsum Wastewater Treatment in Undergraduate Experimental Teaching: Understanding, Development, and Practice. DOI: 10.1021/acsomega.5c05966

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the advantages of decomposing tube furnaces? Achieve Precise Control and High Efficiency in Thermal Processes

- Why must air inlets be equipped with HEPA filters? Preventing Fiber Backflow in Split Tube Furnace Enclosures

- How should crucibles be selected for tube furnaces? Ensure Chemical Purity and Thermal Uniformity

- What is the core function of a high-temperature tube furnace in Pb SA/OSC construction? Precision Atomic Engineering

- How do high-temperature tube furnaces facilitate growth control in MoS2 LPCVD? Precision Synthesis Techniques

- How does a tube resistance furnace contribute to converting industrial sludge into high-activity geopolymer precursors?

- What are the technical requirements for a fixed-bed quartz reactor? Ensure Pure Data in Dry Reforming of Methane

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?