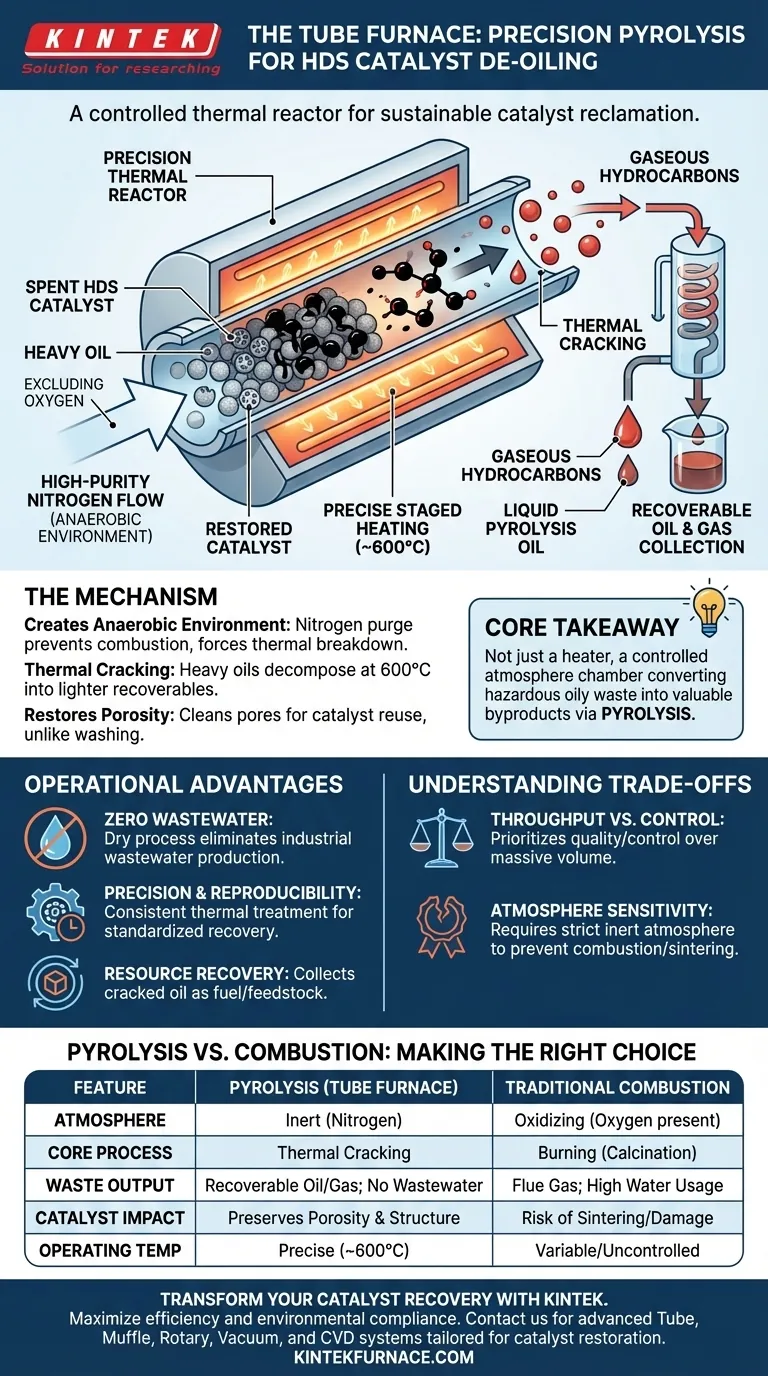

The Tube Furnace acts as a precision thermal reactor that creates the specific anaerobic conditions necessary to reclaim spent catalysts. By utilizing high-purity nitrogen to exclude oxygen and maintaining temperatures around 600°C, it forces the heavy oil contaminants trapped within the catalyst to thermally decompose into lighter hydrocarbons, effectively cleaning the material without the environmental burden of wastewater.

Core Takeaway: The Tube Furnace is not merely a heater; it is a controlled atmosphere chamber that replaces combustion with pyrolysis. This transforms hazardous oily waste into recoverable byproducts (gas and liquid oil) while restoring the catalyst’s porous structure for reuse.

The Mechanism of De-Oiling via Pyrolysis

The primary function of the Tube Furnace in this application is to facilitate thermal cracking under strict atmospheric controls. This process removes contaminants that mechanical washing cannot reach.

Creating an Anaerobic Environment

The furnace utilizes a flow of high-purity nitrogen to purge oxygen from the chamber. This is the critical differentiator between burning (combustion) and cracking (pyrolysis).

By removing oxygen, the furnace prevents the oil from catching fire, which would damage the catalyst's structure and produce uncontrolled emissions. Instead, the environment forces the chemical bonds of the oil to break down due to heat alone.

Thermal Cracking of Heavy Oils

The furnace employs precise, staged heating to reach and maintain a target temperature, typically around 600°C.

At this temperature, the heavy, viscous oil molecules clogging the catalyst cannot survive. They thermally crack (break apart) into smaller, lighter molecules. These convert into gaseous hydrocarbons and liquid pyrolysis oil, which vaporize and exit the material.

Restoring Catalyst Porosity

The ultimate goal of this thermal treatment is the physical restoration of the catalyst.

Spent hydrodesulfurization (HDS) catalysts lose effectiveness because their pores—the tiny tunnels where reactions happen—are plugged with residual oil. The tube furnace effectively empties these pores, recovering the surface area required for the catalyst to function again.

Operational Advantages of the Tube Furnace

Beyond the basic chemistry, the tube furnace offers specific operational benefits that make it superior to open-air calcination for this specific task.

Zero Wastewater Generation

One of the most significant advantages is environmental compliance. Unlike chemical washing methods, the pyrolysis process in a tube furnace is a dry technique.

Because the oil is converted into gas and collectable liquid oil rather than being washed away with water, the process eliminates the production of industrial wastewater, simplifying downstream waste management.

Precision and Reproducibility

Tube furnaces are engineered for high thermal stability and accurate atmosphere control.

Whether dealing with waste salts or HDS catalysts, the ability to strictly regulate heating rates and dwell times ensures that every batch undergoes the exact same thermal stress. This consistency is vital for standardized recovery rates and ensuring the catalyst substrate is not overheated or damaged.

Understanding the Trade-offs

While the tube furnace is highly effective for de-oiling, you must consider the operational constraints inherent in the technology.

Throughput vs. Control

Tube furnaces prioritize environmental control over massive volume.

They are typically batch or continuous-flow systems with limited cross-sectional area. While they provide superior quality control for the de-oiling process, they may have lower throughput compared to large-scale rotary kilns or industrial incinerators used for less sensitive materials.

Atmosphere Sensitivity

The success of the process relies entirely on the integrity of the inert atmosphere.

If the nitrogen flow is interrupted or a seal fails, oxygen will enter the chamber at 600°C. This will instantly shift the process from controlled pyrolysis to uncontrolled combustion, potentially sintering the catalyst and destroying its active sites.

Making the Right Choice for Your Goal

The decision to use a tube furnace for HDS catalyst recovery depends on your specific operational priorities.

- If your primary focus is Environmental Compliance: The tube furnace is the optimal choice because it eliminates wastewater generation and allows for the capture of volatile organic compounds.

- If your primary focus is Catalyst Longevity: The precise temperature control prevents thermal shock and sintering, ensuring the catalyst's pore structure remains intact for future use.

- If your primary focus is Resource Recovery: The anaerobic process allows you to collect the cracked liquid pyrolysis oil as a fuel source or chemical feedstock, rather than burning it off as waste.

By leveraging the controlled atmosphere of a tube furnace, you turn a waste disposal problem into a resource recovery opportunity.

Summary Table:

| Feature | Pyrolysis in Tube Furnace | Traditional Combustion |

|---|---|---|

| Atmosphere | Inert (High-purity Nitrogen) | Oxidizing (Oxygen present) |

| Core Process | Thermal Cracking | Burning (Calcination) |

| Waste Output | Recoverable Oil/Gas; No Wastewater | Flue Gas; High Water Usage |

| Catalyst Impact | Preserves Porosity & Structure | Risk of Sintering/Damage |

| Operating Temp | Precise (Approx. 600°C) | Often Variable/Uncontrolled |

Transform Your Catalyst Recovery Process Today

Maximize your laboratory efficiency and environmental compliance with KINTEK’s advanced thermal solutions. Backed by expert R&D and precision manufacturing, we provide high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems tailored specifically for catalyst restoration and pyrolysis applications.

Whether you need customizable heating rates for sensitive HDS catalysts or robust atmospheric control to eliminate industrial wastewater, our experts are ready to design a system for your unique needs.

Ready to upgrade your thermal processing? Contact us today to get a quote!

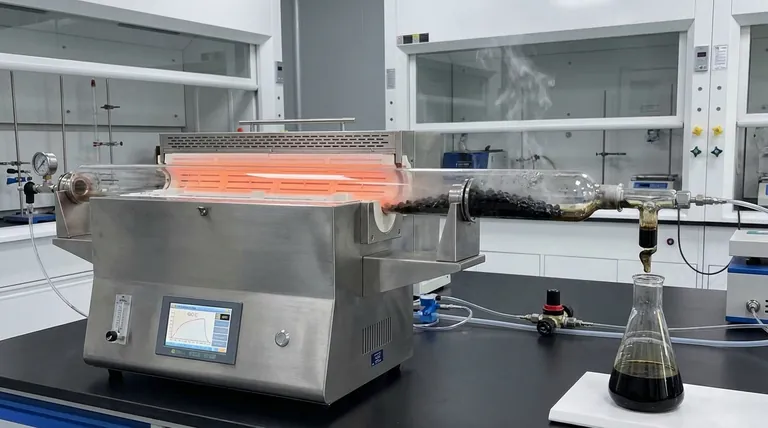

Visual Guide

References

- Hong Xin, Ganfeng Tu. Recovering Attached Crude Oil from Hydrodesulfurization Spent Catalysts. DOI: 10.3390/recycling10010010

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is a multi zone tube furnace used for? Unlock Precision Thermal Processing for Advanced Materials

- What role does a high-purity quartz tube furnace play in graphene growth? Achieve Conformal Optical Resonator Coating

- What is the primary function of a tube resistance furnace in g-C3N4 synthesis? Achieve Precise Thermal Condensation

- What is the basic working principle of a tube furnace? Master Precise Heating for Material Processing

- What is the specific purpose of tilting a tube resistance furnace during synthesis? Maximize Yield & Crystal Quality

- How does tube furnace cracking compare to fuel furnaces in terms of efficiency? Discover Higher Efficiency and Precision

- What are the primary uses of tube furnaces in academic and industrial settings? Unlock Precision Thermal Processing

- What is the function of autoclaves and tube reactors in hydrometallurgical leaching? Unlock Refractory Ore Potential