In short, a multi-zone tube furnace is used for sophisticated thermal processes that require a precise, engineered temperature profile across the length of the furnace tube. Unlike a standard single-zone furnace that creates one uniform hot area, a multi-zone furnace uses multiple, independently controlled heating sections to create specific temperature gradients, steps, or an extended uniform zone.

The core value of a multi-zone furnace is not just heating, but the ability to precisely control the temperature gradient. This unlocks complex material synthesis, purification, and crystal growth processes that are impossible to achieve with a single, uniform heat source.

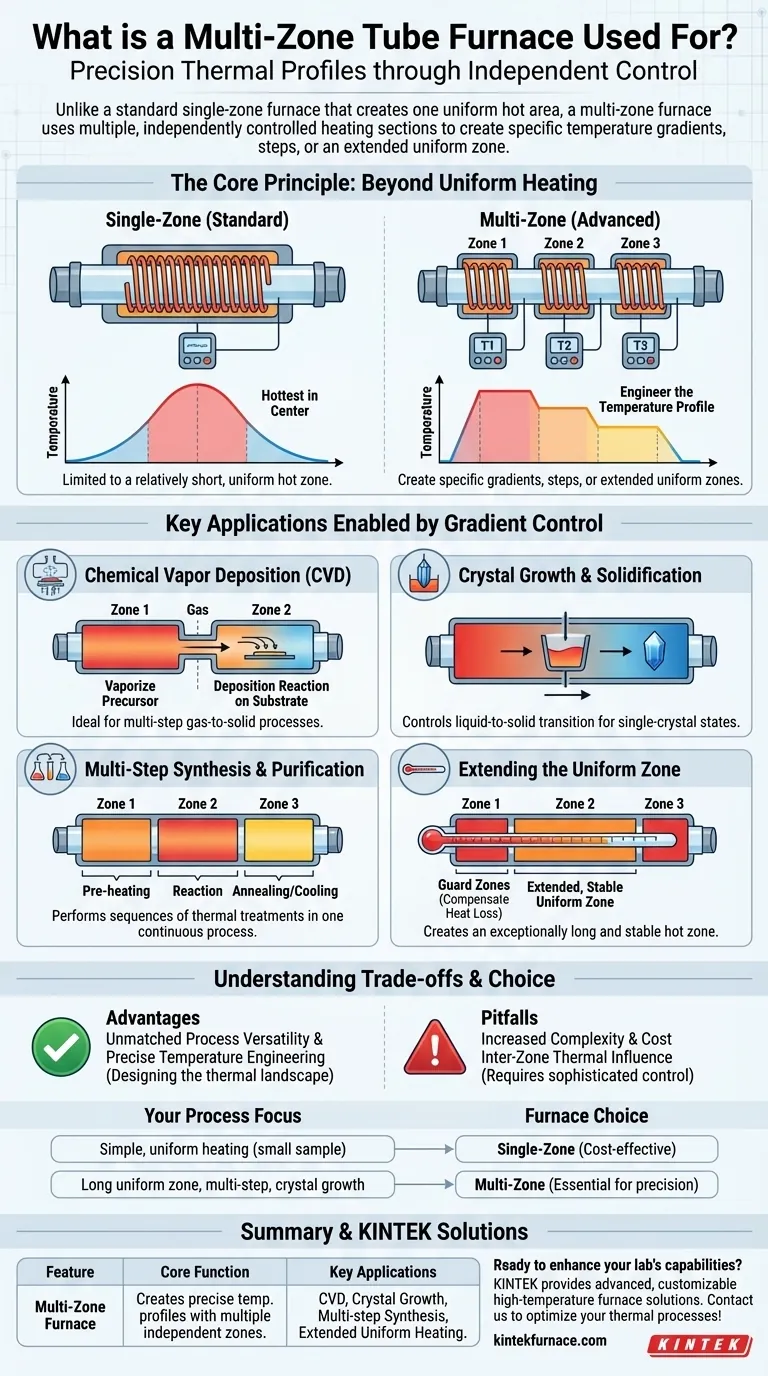

The Core Principle: Beyond Uniform Heating

A standard tube furnace is a simple, effective tool for heating samples in a controlled atmosphere. However, its usefulness is limited by its fundamental design. Understanding this limitation is key to seeing the value of a multi-zone system.

The Single-Zone Limitation

A single-zone furnace has one set of heating elements and one controller. This creates a temperature profile that is hottest in the center and naturally cools toward the ends of the tube due to heat loss.

While useful, this design provides only a relatively short, uniform hot zone. Any process requiring different temperatures at different points, or a very long uniform zone, is difficult to manage.

Introducing Multiple Zones for Gradient Control

A multi-zone furnace divides the heating elements into two, three, or more independent sections, each with its own thermocouple and controller. This allows you to engineer the temperature profile along the tube.

You can set each zone to a different temperature, creating a precise thermal gradient. This is the defining feature and primary advantage of a multi-zone furnace. For example, a three-zone furnace can be programmed to create a stepped profile, a sloped gradient, or an exceptionally long and stable uniform hot zone.

Key Applications Enabled by Gradient Control

The ability to create custom temperature profiles makes multi-zone furnaces essential for several advanced laboratory and industrial processes.

Chemical Vapor Deposition (CVD)

CVD is a process where a material is deposited from a vapor or gas onto a substrate. A multi-zone furnace is ideal for this.

A common setup involves using the first zone to vaporize a precursor material at a specific temperature, with the subsequent zone(s) set to a different, optimal temperature for the deposition reaction to occur on the substrate.

Crystal Growth and Solidification

Techniques like the Bridgman-Stockbarger method for growing crystals require slowly moving a material through a precise temperature gradient to control the transition from liquid to a solid, single-crystal state.

A multi-zone furnace can create and maintain this exact stationary gradient, while the material is moved through it, or the temperature profile itself can be programmed to move electronically.

Multi-Step Synthesis and Purification

Many advanced materials require a sequence of thermal treatments. A multi-zone furnace can perform these steps in a single, continuous process.

For example, a material can be moved through a pre-heating zone, into a high-temperature reaction zone, and finally into a controlled annealing or cooling zone, all within the same furnace tube.

Extending the Uniform Zone

A three-zone furnace is also the best tool for creating a long and highly uniform temperature zone.

The two outer "guard" zones are set to a slightly higher temperature to actively compensate for the natural heat loss at the ends. This forces the central zone to be extremely stable and uniform over a much greater length than is possible with a single-zone design.

Understanding the Trade-offs

While powerful, a multi-zone furnace is not always the necessary choice. Its advantages come with specific considerations.

Advantage: Unmatched Process Versatility

A multi-zone furnace can do everything a single-zone furnace can, but it also provides the flexibility to create custom thermal profiles for more complex experiments.

Advantage: Precise Temperature Engineering

The primary benefit is the ability to move beyond simple heating and into designing the thermal landscape for your process, enabling otherwise impossible research and production.

Pitfall: Increased Complexity and Cost

The additional heating elements, thermocouples, and controllers make multi-zone furnaces more expensive and complex to operate than their single-zone counterparts. Programming and calibration require more attention to detail.

Pitfall: Inter-Zone Thermal Influence

Because the zones are physically adjacent, the heat from one zone can influence its neighbor. Sophisticated controllers are required to manage this interaction and maintain the integrity of the desired temperature profile.

Making the Right Choice for Your Process

Selecting the correct furnace depends entirely on the requirements of your thermal process.

- If your primary focus is simple, uniform heating of a small sample: A single-zone furnace is more than sufficient and the most cost-effective solution.

- If your primary focus is creating a very long, stable, and uniform hot zone: A three-zone furnace is the ideal tool, as it can actively compensate for end-of-furnace heat losses.

- If your primary focus is a multi-step process like CVD or purification: A multi-zone furnace is essential for creating the necessary sequence of different temperature zones.

- If your primary focus is advanced material science like crystal growth: A multi-zone furnace is the only tool that provides the required precision for engineering specific temperature gradients.

Ultimately, choosing a multi-zone furnace is a decision to invest in process control and experimental capability.

Summary Table:

| Feature | Description |

|---|---|

| Core Function | Creates precise temperature profiles with multiple, independently controlled heating zones. |

| Key Applications | Chemical Vapor Deposition (CVD), crystal growth, multi-step synthesis, and extended uniform heating. |

| Advantages | Unmatched versatility, precise temperature engineering, and ability to perform complex thermal processes. |

| Considerations | Higher cost, increased complexity, and potential inter-zone thermal influence requiring careful management. |

Ready to enhance your lab's capabilities with a custom multi-zone tube furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how we can optimize your thermal processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing