In short, a fluidized bed vertical tube furnace offers superior operational advantages primarily through exceptional temperature uniformity, high heat transfer efficiency, and precise process control. These benefits stem from its unique method of suspending solid particles in an upward-flowing gas, which creates a fluid-like state for highly effective and consistent heating.

The core advantage is not the furnace itself, but the fluidization process it enables. By turning solid particles into a dynamic, suspended bed, it creates a near-ideal environment for rapid and uniform heat and mass transfer, solving many problems inherent in static heating methods.

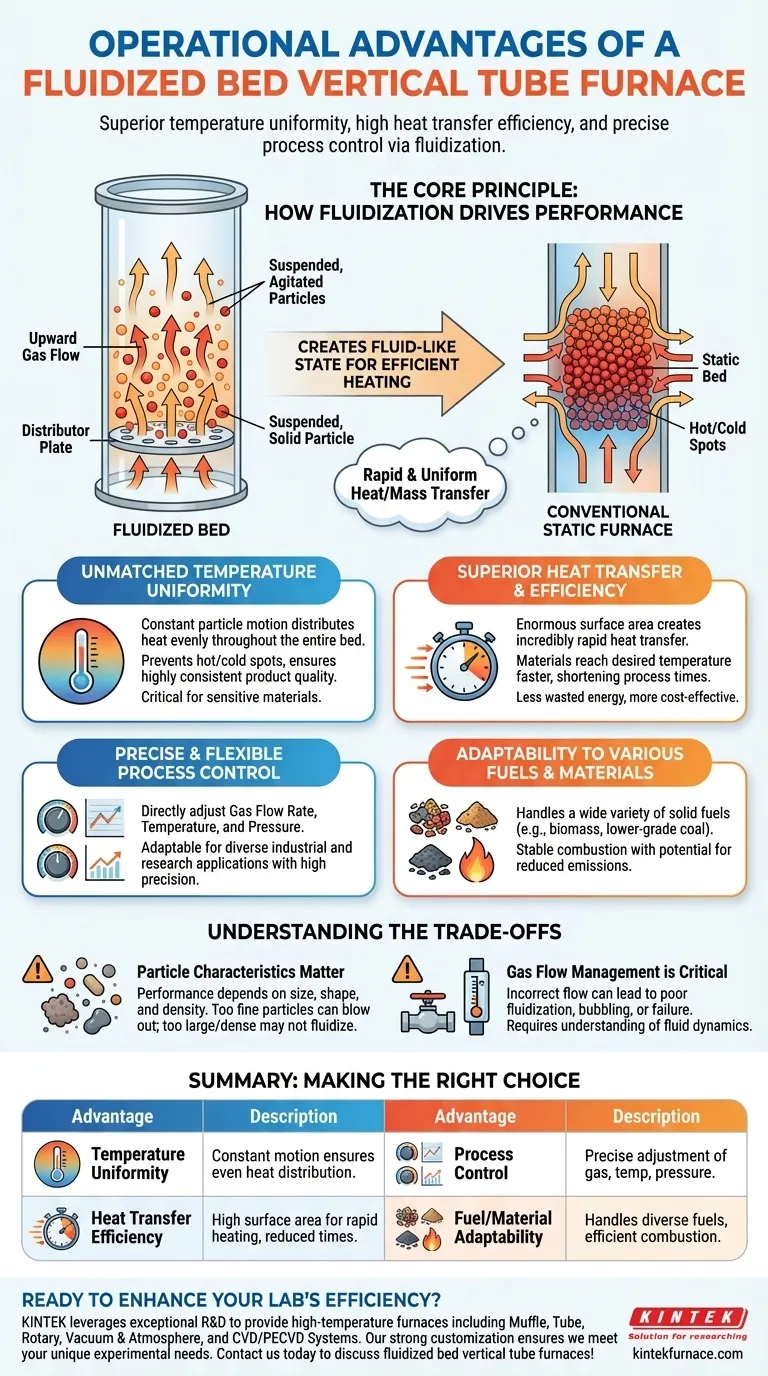

The Core Principle: How Fluidization Drives Performance

To understand the furnace's advantages, you must first understand its central mechanism. It doesn't just heat materials; it transforms their physical state to optimize the process.

What is a Fluidized Bed?

A fluidized bed is created when a flow of gas is passed upward through a bed of solid particulate material.

By carefully controlling the gas flow rate and pressure, the gas-solid friction counteracts gravity, causing the particles to become suspended and agitated. This mixture of gas and solids behaves like a boiling liquid.

The Impact on Heat and Mass Transfer

This fluid-like state is the key to the furnace's performance. The constant motion and mixing of particles dramatically increase the contact surface area between the gas and the solid material.

This maximized contact ensures that heat is transferred from the gas to the particles—or from particle to particle—with extreme speed and efficiency.

Achieving Unparalleled Uniformity

In a conventional furnace, materials can develop hot spots or cold spots. The constant, turbulent motion within a fluidized bed eliminates this issue entirely.

Every particle is continuously moving, ensuring the temperature across the entire bed is exceptionally uniform.

Key Operational Advantages Explained

The fluidization principle directly translates into several tangible benefits during operation, making this furnace a powerful tool for specific applications.

Unmatched Temperature Uniformity

Because the solid particles are in constant motion, heat is distributed evenly throughout the entire volume. This prevents localized overheating or under-heating, which is critical for sensitive materials and chemical reactions.

This results in a highly consistent product quality that is difficult to achieve in other furnace types.

Superior Heat Transfer and Efficiency

The enormous surface area created by suspending the particles allows for incredibly rapid heat transfer. Materials reach the desired temperature much faster, which shortens process times and improves throughput.

This high efficiency also means less wasted energy, leading to more energy-saving and cost-effective operation.

Precise and Flexible Process Control

The entire system is governed by physical parameters that you can adjust with high precision. By manipulating the gas flow rate, temperature, and pressure, you have direct control over the fluidization state and the reaction environment.

This flexibility allows the furnace to be adapted for a wide range of industrial processes, research applications, and material types.

Adaptability to Various Fuels and Materials

The robust nature of the fluidized bed allows it to handle a wide variety of solid fuels, including lower-grade options like biomass or different types of coal.

The stable and efficient combustion process ensures high temperatures can be achieved regardless of the fuel source, with exhaust gases that can meet strict environmental emission standards after purification.

Understanding the Trade-offs

While powerful, this technology is not a universal solution. Its operational advantages depend on careful system design and management.

Particle Characteristics Matter

The performance of a fluidized bed is highly dependent on the size, shape, and density of the solid particles. Materials that are too fine may be blown out of the furnace, while those that are too large or dense may not fluidize properly.

Your material must be suitable for fluidization or be processed to meet the required specifications.

Gas Flow Management is Critical

The system's success lives or dies by the gas flow. An incorrect flow rate can lead to poor fluidization (sluggishness), bubbling, or even complete failure of the process.

Operating this furnace requires a more sophisticated understanding of fluid dynamics compared to a simple static furnace.

Making the Right Choice for Your Application

To determine if this furnace is the correct tool, align its core strengths with your primary goal.

- If your primary focus is process efficiency and speed: This furnace excels due to its rapid heat transfer, which shortens cycle times and increases throughput.

- If your primary focus is product quality and consistency: The exceptional temperature uniformity ensures every particle is treated identically, eliminating defects from hot or cold spots.

- If your primary focus is research and development: The precise control over gas flow, temperature, and pressure provides a highly adjustable environment for experimenting with novel materials and reactions.

- If your primary focus is fuel flexibility and environmental compliance: The furnace's ability to efficiently burn diverse solid fuels while maintaining low emissions makes it a strong choice for sustainable energy applications.

Ultimately, choosing a fluidized bed vertical tube furnace is a decision to prioritize dynamic control and uniformity over operational simplicity.

Summary Table:

| Advantage | Description |

|---|---|

| Temperature Uniformity | Constant particle motion ensures even heat distribution, eliminating hot/cold spots for consistent results. |

| Heat Transfer Efficiency | High surface area from fluidization enables rapid heating, reducing process times and energy waste. |

| Process Control | Precise adjustment of gas flow, temperature, and pressure allows flexible adaptation to various applications. |

| Fuel and Material Adaptability | Handles diverse solid fuels and materials, supporting efficient combustion and environmental compliance. |

Ready to enhance your lab's efficiency with advanced furnace solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs—whether you're focused on process speed, product quality, or fuel flexibility. Contact us today to discuss how our fluidized bed vertical tube furnaces can deliver superior performance for your applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis