A graphite crucible serves as the foundational melting vessel and thermal interface in the preparation of Al2214-B4C-graphite hybrid composites. It functions primarily to contain the aluminum alloy matrix within an electric furnace, utilizing its specific material properties to facilitate the melting process before reinforcement particles are introduced.

The graphite crucible leverages superior thermal conductivity and chemical stability to efficiently melt the aluminum matrix while minimizing contamination, providing a stable platform for the subsequent mechanical stirring process.

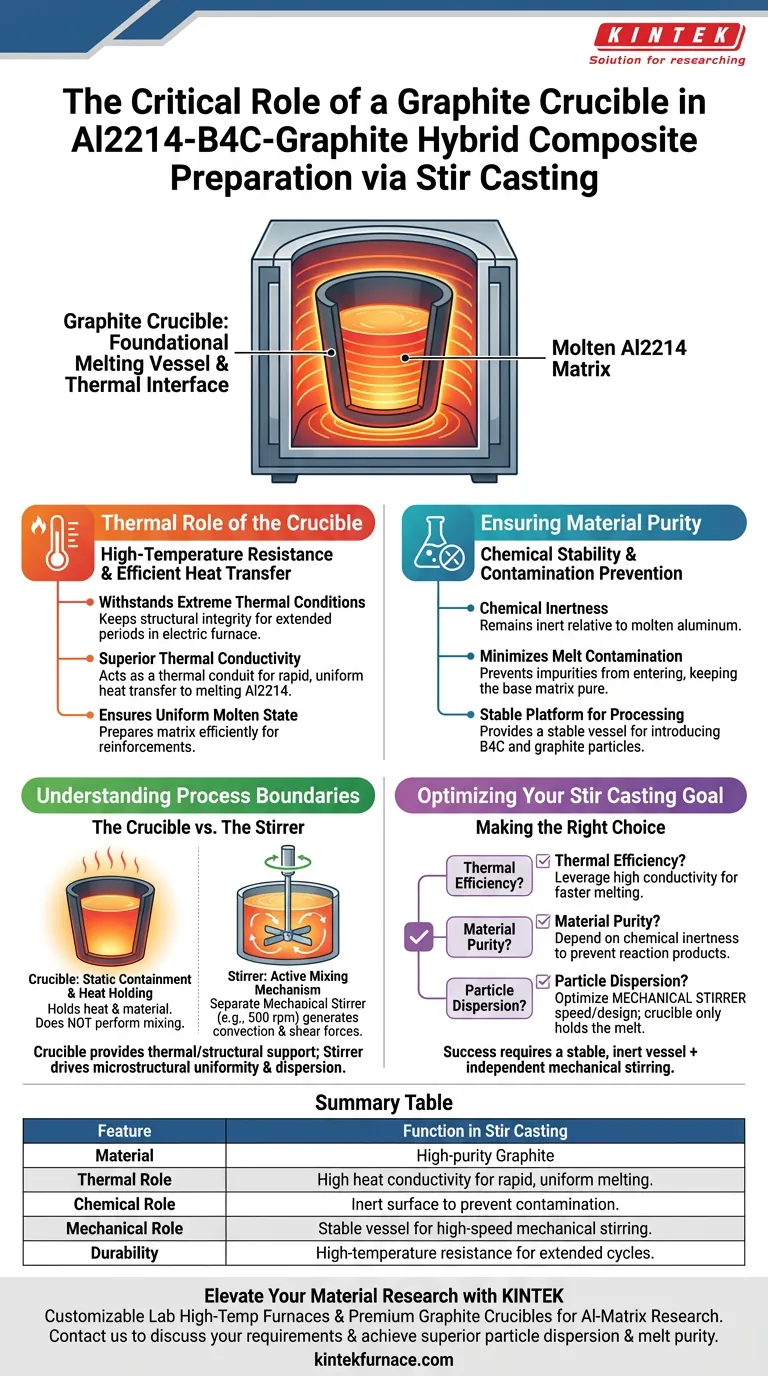

The Thermal Role of the Crucible

High-Temperature Resistance

The stir casting process requires maintaining the aluminum matrix in a molten state for extended periods.

A graphite crucible is selected for its ability to withstand these extreme thermal conditions without degrading. It maintains structural integrity inside the electric furnace, ensuring the safety and stability of the molten pool.

Efficient Heat Transfer

Beyond simply holding the metal, the crucible acts as a thermal conduit.

It possesses superior thermal conductivity, which allows for the rapid and even transfer of heat from the furnace elements to the Al2214 alloy. This ensures the matrix reaches its melting point efficiently, preparing it for the addition of reinforcements.

Ensuring Material Purity

Chemical Stability

One of the most critical challenges in casting aluminum alloys is preventing impurities from entering the melt.

The graphite crucible offers chemical stability, meaning it is inert relative to the molten aluminum. This property is essential for minimizing melt contamination, ensuring that the base matrix remains pure before the B4C and graphite particles are added.

A Stable Platform for Processing

The crucible acts as the static environment where the dynamic processing takes place.

It provides the foundational platform necessary to hold the molten metal. This stability is required to safely introduce the reinforcement particles and to accommodate the mechanical equipment used in later steps.

Understanding the Process Boundaries

The Crucible vs. The Stirrer

It is vital to distinguish between the role of the containment vessel and the active mixing mechanism.

While the graphite crucible holds the heat and the material, it does not perform the mixing. As noted in supplementary technical context, a separate mechanical stirrer is required to generate the convection and shear forces needed to disperse the particles.

The Limits of Static Containment

The crucible creates the environment for melting, but it cannot prevent particle agglomeration on its own.

The uniform dispersion of hard B4C and self-lubricating graphite particles relies on the mechanical action of the stirrer (often at speeds around 500 rpm), not the crucible. The crucible’s role is strictly thermal and structural support, whereas the stirrer drives microstructural uniformity.

Making the Right Choice for Your Goal

To optimize the stir casting of Al2214 hybrid composites, you must leverage the distinct functions of your equipment:

- If your primary focus is thermal efficiency: Rely on the graphite crucible's high conductivity to reduce the time required to bring the matrix to a uniform molten state.

- If your primary focus is material purity: Depend on the crucible's chemical inertness to prevent reaction products from the vessel walls from contaminating the sensitive aluminum alloy.

- If your primary focus is particle dispersion: Understand that the crucible only holds the melt; you must optimize the mechanical stirrer's speed and design to break up particle clusters.

Success in stir casting depends on a stable, chemically inert vessel that allows the mechanical stirring process to function without interference.

Summary Table:

| Feature | Function in Stir Casting |

|---|---|

| Material | High-purity Graphite |

| Thermal Role | High heat conductivity for rapid, uniform melting |

| Chemical Role | Inert surface to prevent aluminum matrix contamination |

| Mechanical Role | Stable vessel for high-speed mechanical stirring (e.g., 500 rpm) |

| Durability | High-temperature resistance for extended processing cycles |

Elevate Your Material Research with KINTEK

Precision in hybrid composite preparation starts with the right equipment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside premium graphite crucibles and lab high-temp furnaces—all fully customizable to your unique Al-matrix research needs.

Ready to achieve superior particle dispersion and melt purity? Contact us today to discuss your custom furnace and crucible requirements with our technical specialists.

Visual Guide

References

- Revanna Kambaiah, Anteneh Wogasso Wodajo. Mechanical‐wear behavior and microstructure analysis of Al2214 alloy with <scp>B<sub>4</sub>C</scp> and graphite particles hybrid composites. DOI: 10.1002/eng2.12876

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary purpose of using a high-purity quartz vacuum ampule? Unlock High-Quality WSe2 Crystal Growth

- Why is a platinum-gold alloy crucible utilized during the glass melting process? Achieve Unmatched Purity

- How do vacuum systems assist in pure thin film growth? Enhance PLD Chemical Purity with Turbo-Molecular Pumps

- Why use high-purity quartz glass tubes for copper sulfide synthesis? Ensure Thermal Stability & Purity

- Why are high-purity graphite crucibles with lids used for ilmenite reduction? Control Your Micro-Reducing Atmosphere

- Why is a U-shaped quartz reactor required for H2-TPR? Ensure Precision for Cu–Ce/HZSM-5 Analysis

- Why is a graphite crucible used for melting Al-Mg-Si alloys? Superior Purity & Thermal Efficiency

- How does a heating stage contribute to the quality of multi-material 3D printing? Optimize Precision and Stability