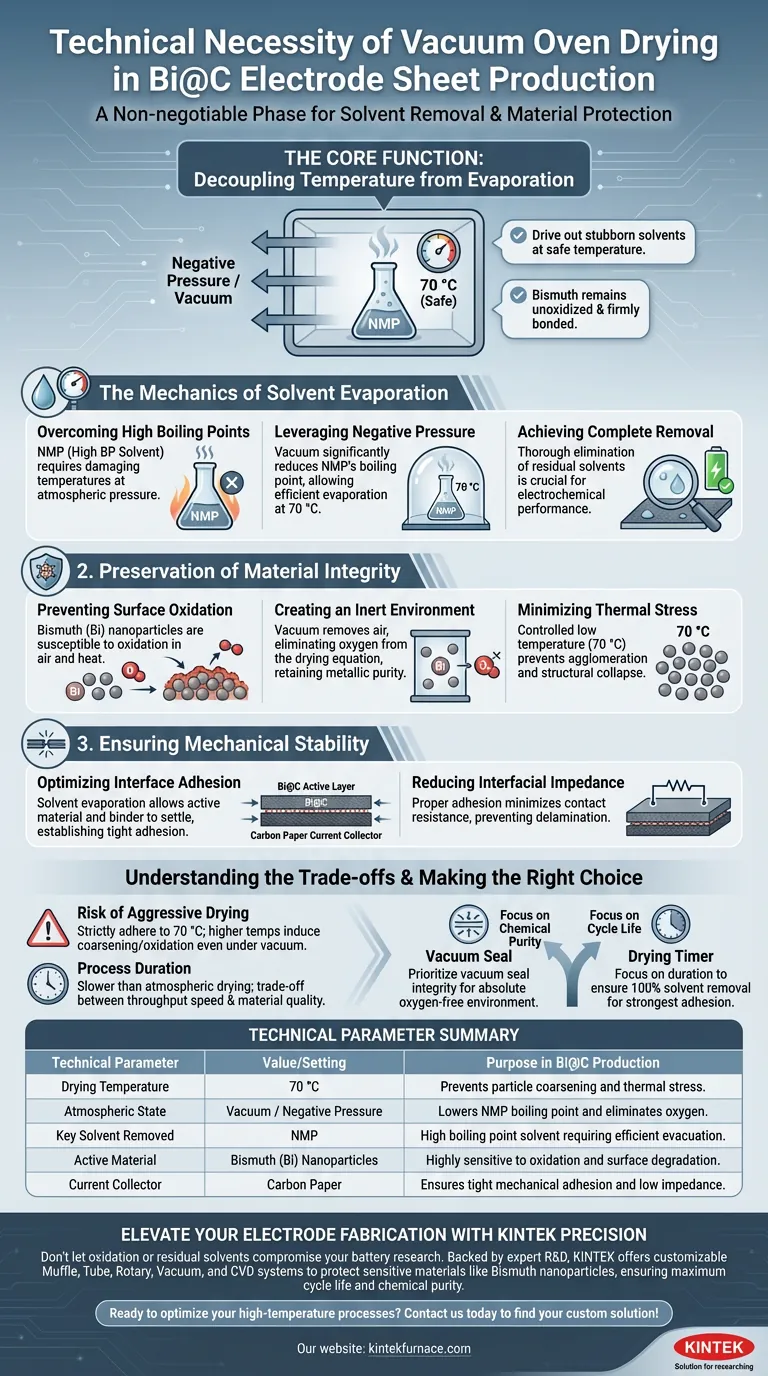

The vacuum oven drying step is a non-negotiable phase in the fabrication of Bi@C (Bismuth/Carbon) electrode sheets. It serves the dual technical purpose of effectively removing high-boiling-point solvents, specifically NMP, while creating a protective, oxygen-deprived environment. This process prevents the chemical degradation of Bismuth nanoparticles that would inevitably occur during standard air drying.

The core function of this step is to decouple temperature from evaporation. By lowering the ambient pressure, you can drive out stubborn solvents at a safe temperature (70 °C), ensuring the Bismuth active material remains unoxidized and firmly bonded to the current collector.

The Mechanics of Solvent Evaporation

Overcoming High Boiling Points

The production of electrode slurry typically utilizes N-Methyl-2-pyrrolidone (NMP), a solvent with a high boiling point. Removing this solvent at atmospheric pressure would require temperatures that could damage the active materials.

Leveraging Negative Pressure

By utilizing a vacuum environment, the boiling point of NMP is significantly reduced. This allows the solvent to evaporate efficiently at a moderate temperature of 70 °C.

Achieving Complete Removal

This step ensures the thorough elimination of residual solvents from the coated substrate. Incomplete removal would lead to poor electrochemical performance and potential side reactions inside the battery.

Preservation of Material Integrity

Preventing Surface Oxidation

Bismuth (Bi) nanoparticles are highly susceptible to oxidation, particularly when heated. A standard drying oven would expose these particles to hot air, leading to the formation of unwanted oxides.

Creating an Inert Environment

The vacuum oven removes air from the chamber, eliminating oxygen from the drying equation. This ensures the Bi@C material retains its metallic purity and intended chemical composition.

Minimizing Thermal Stress

Drying at a lower controlled temperature (70 °C) prevents the thermal stress that could lead to particle agglomeration or structural collapse. This maintains the specific morphology required for ion transport.

Ensuring Mechanical Stability

Optimizing Interface Adhesion

As the solvent evaporates under vacuum, the remaining active material and binder settle onto the substrate. This process is critical for establishing tight adhesion between the active Bi@C layer and the carbon paper current collector.

Reducing Interfacial Impedance

Proper adhesion minimizes the contact resistance between the material and the collector. Without this robust mechanical bond, the electrode would suffer from delamination and poor conductivity during cycling.

Understanding the Trade-offs

The Risk of aggressive Drying

While vacuum drying accelerates evaporation, setting the temperature too high—even under vacuum—can be detrimental. For Bi@C, adhering strictly to 70 °C is vital; higher temperatures may still induce particle coarsening or minor oxidation if the vacuum seal is imperfect.

Process Duration

Vacuum drying is often a slower process compared to high-heat atmospheric drying. It requires a longer duration to ensure solvents are evacuated from the deepest pores of the electrode, representing a trade-off between throughput speed and material quality.

Making the Right Choice for Your Goal

To maximize the quality of your Bi@C electrode sheets, tailor your focus based on your specific performance metrics:

- If your primary focus is Chemical Purity: Prioritize the vacuum seal integrity to ensure an absolute oxygen-free environment, preventing Bismuth oxidation.

- If your primary focus is Cycle Life: Focus on the duration of the drying phase to ensure 100% solvent removal, which guarantees the strongest physical adhesion to the current collector.

The success of the Bi@C electrode hinges on balancing efficient solvent removal with the delicate preservation of the Bismuth nanostructure.

Summary Table:

| Technical Parameter | Value/Setting | Purpose in Bi@C Production |

|---|---|---|

| Drying Temperature | 70 °C | Prevents particle coarsening and thermal stress |

| Atmospheric State | Vacuum / Negative Pressure | Lowers NMP boiling point and eliminates oxygen |

| Key Solvent Removed | NMP (N-Methyl-2-pyrrolidone) | High boiling point solvent requiring efficient evacuation |

| Active Material | Bismuth (Bi) Nanoparticles | Highly sensitive to oxidation and surface degradation |

| Current Collector | Carbon Paper | Ensures tight mechanical adhesion and low impedance |

Elevate Your Electrode Fabrication with KINTEK Precision

Don’t let oxidation or residual solvents compromise your battery research. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of your lab.

Our high-temp vacuum furnaces provide the precise thermal control and atmospheric integrity required to protect sensitive materials like Bismuth nanoparticles, ensuring maximum cycle life and chemical purity for your unique needs.

Ready to optimize your high-temperature processes? Contact us today to find your custom solution!

Visual Guide

References

- Xiaoqing Dong, Chaolin Li. Bismuth Nanoparticles Encapsulated in a Porous Carbon Skeleton as Stable Chloride-Storage Electrodes for Seawater Desalination. DOI: 10.3390/batteries10010035

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a vacuum drying oven play in the preparation of anhydrous calcium chloride? Ensuring High-Purity Results

- What advantages does a laboratory vacuum oven offer over a conventional oven for Pb SA/OSC catalyst drying?

- What are the main types of vacuum furnace chambers and their temperature ranges? Find the Perfect Fit for Your Lab

- How do vacuum-based systems like PLD and Magnetron Sputtering contribute to superconducting thin films? Expert Guide

- What furnace technology is needed for higher temperature sintering? Choose Vacuum or Walking Beam for Optimal Results

- Why are specific temperature gradients utilized in a vacuum drying oven? Master Mixed Matrix Membrane Preparation

- How are temperature and pressure controlled in vacuum sintering? Achieve Precise Material Densification and Performance

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control