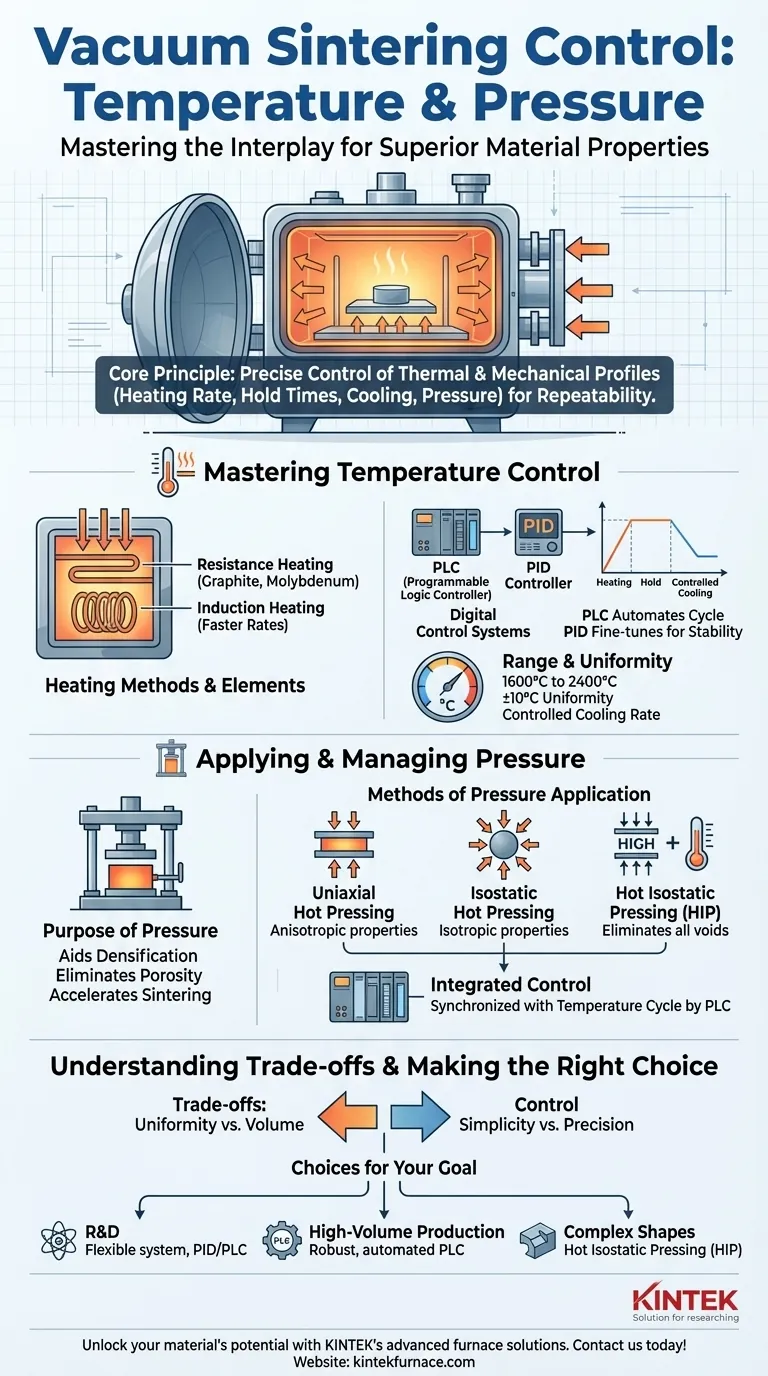

In vacuum sintering, temperature and pressure are managed through a sophisticated interplay of physical heating mechanisms, pressure application methods, and integrated digital control systems. These systems allow for precise, programmable control over the entire process cycle, with heating achieved via resistance or induction elements and pressure applied uniaxially or isostatically, all governed by automated PLC and PID controllers.

The core principle is not just to reach a target temperature and pressure, but to precisely control the entire thermal and mechanical profile—heating rate, hold times, cooling rate, and pressure application—to achieve desired final material properties with high repeatability.

Mastering Temperature Control

Achieving specific material densities and microstructures begins with precise command over the thermal environment. Modern furnaces offer a high degree of control over the entire heating and cooling cycle.

Heating Methods and Elements

The method of generating heat is foundational. Resistance heating, using materials like graphite or molybdenum, is common. Induction heating offers faster heating rates for specific conductive materials, while other methods like microwave heating exist for specialized applications.

This flexibility allows the furnace to be tailored to the specific thermal properties and processing requirements of the material being sintered.

Digital Control Systems

The "brain" of the furnace is its control system. PID (Proportional-Integral-Derivative) controllers are crucial for fine-tuning temperature, actively adjusting power to prevent overshooting the target and maintaining a stable hold.

This is often managed by a PLC (Programmable Logic Controller), which automates the entire pre-programmed cycle, including heating rates, hold times, and cooling. This ensures process consistency and repeatability from one batch to the next.

Temperature Range and Uniformity

Vacuum sintering furnaces are designed for high-performance applications, with capabilities often reaching ultra-high temperatures of 1600°C to 2400°C.

Equally important is temperature uniformity, typically maintained within ±10°C across the high-temperature zone. This ensures that all parts of a component, or all components in a batch, are processed under identical conditions, preventing variations in density or performance.

Controlled Cooling

The process doesn't end when the peak temperature is reached. The cooling rate is also a critical, controlled variable. Methods like controlled gas cooling are used to manage the rate of cooling, which can significantly influence the final microstructure and mechanical properties of the material.

Applying and Managing Pressure

In vacuum pressure sintering, controlled external pressure is applied to aid densification, eliminate residual porosity, and accelerate the sintering process at lower temperatures.

The Purpose of Pressure

While vacuum removes atmospheric contaminants and entrapped gases, applied pressure actively forces material particles together. This mechanical assistance is key to achieving near-full theoretical density, which is often impossible with vacuum alone.

Methods of Pressure Application

There are three primary methods for applying pressure during sintering:

- Uniaxial Hot Pressing: Pressure is applied along a single axis. This is a direct and relatively simple method but can result in anisotropic properties (different properties in different directions).

- Isostatic Hot Pressing: Pressure is applied uniformly from all directions, typically using a gas medium. This results in more uniform densification and isotropic properties.

- Hot Isostatic Pressing (HIP): This process combines very high isostatic pressure with high temperature, representing the gold standard for eliminating all residual porosity in critical components.

Integrated Control

The application of pressure is not an independent step. It is precisely timed and synchronized with the temperature cycle by the central PLC system. This ensures pressure is applied and released at the optimal moments in the process to achieve the desired outcome.

Understanding the Process Trade-offs

While powerful, these control systems come with inherent complexities and trade-offs that must be managed.

Uniformity vs. Volume

Achieving tight temperature uniformity becomes exponentially more challenging as the furnace volume increases. Large-scale production requires sophisticated furnace engineering to ensure every component experiences the same thermal profile.

Control Simplicity vs. Precision

Manual controls or simple programmers may be sufficient for basic tasks, but they lack the repeatability and precision of a fully automated PLC system. However, PLC systems require significant upfront investment in programming, setup, and operator training.

Pressure Method and Component Geometry

Uniaxial pressing is best suited for simple shapes like discs or blocks. Complex, three-dimensional shapes greatly benefit from isostatic pressing, which ensures pressure is applied evenly to all surfaces, but the equipment is more complex and costly.

Making the Right Choice for Your Goal

The optimal control strategy depends entirely on your specific material and manufacturing objectives.

- If your primary focus is material research and development: You need a flexible system with fully programmable PID/PLC control to easily test and validate new processing cycles.

- If your primary focus is high-volume production: Prioritize a robust and fully automated PLC system to ensure maximum repeatability, process safety, and operational efficiency.

- If your primary focus is achieving maximum density in complex shapes: Hot Isostatic Pressing (HIP) is the definitive choice for its ability to apply uniform pressure and eliminate internal voids.

Mastering the precise and synchronized control of temperature and pressure is the key to unlocking the full performance potential of advanced sintered materials.

Summary Table:

| Control Aspect | Key Methods | Typical Range/Uniformity | Purpose |

|---|---|---|---|

| Temperature | Resistance/Induction Heating, PID/PLC Control | 1600°C to 2400°C, ±10°C uniformity | Achieve desired density and microstructure |

| Pressure | Uniaxial, Isostatic, Hot Isostatic Pressing (HIP) | Applied uniformly or uniaxially | Eliminate porosity, accelerate sintering |

Unlock the full potential of your materials with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precise control systems for vacuum sintering. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental needs. Whether for R&D, high-volume production, or complex shapes, KINTEK ensures repeatable, efficient processes. Contact us today to discuss how we can enhance your sintering outcomes!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction