For successful high-temperature sintering, particularly in the 1200°C to 1300°C range, the choice of furnace technology is critical and depends heavily on your material's sensitivity. The two primary technologies for this application are Vacuum Furnaces for ultimate purity and atmospheric control, and Walking Beam Furnaces for specific, continuous processes involving materials like chrome alloys.

The fundamental decision is not about achieving high temperatures, but about controlling the environment at those temperatures. Your material's sensitivity to atmospheric gases like oxygen will be the primary factor guiding your choice between a vacuum or a controlled-atmosphere furnace.

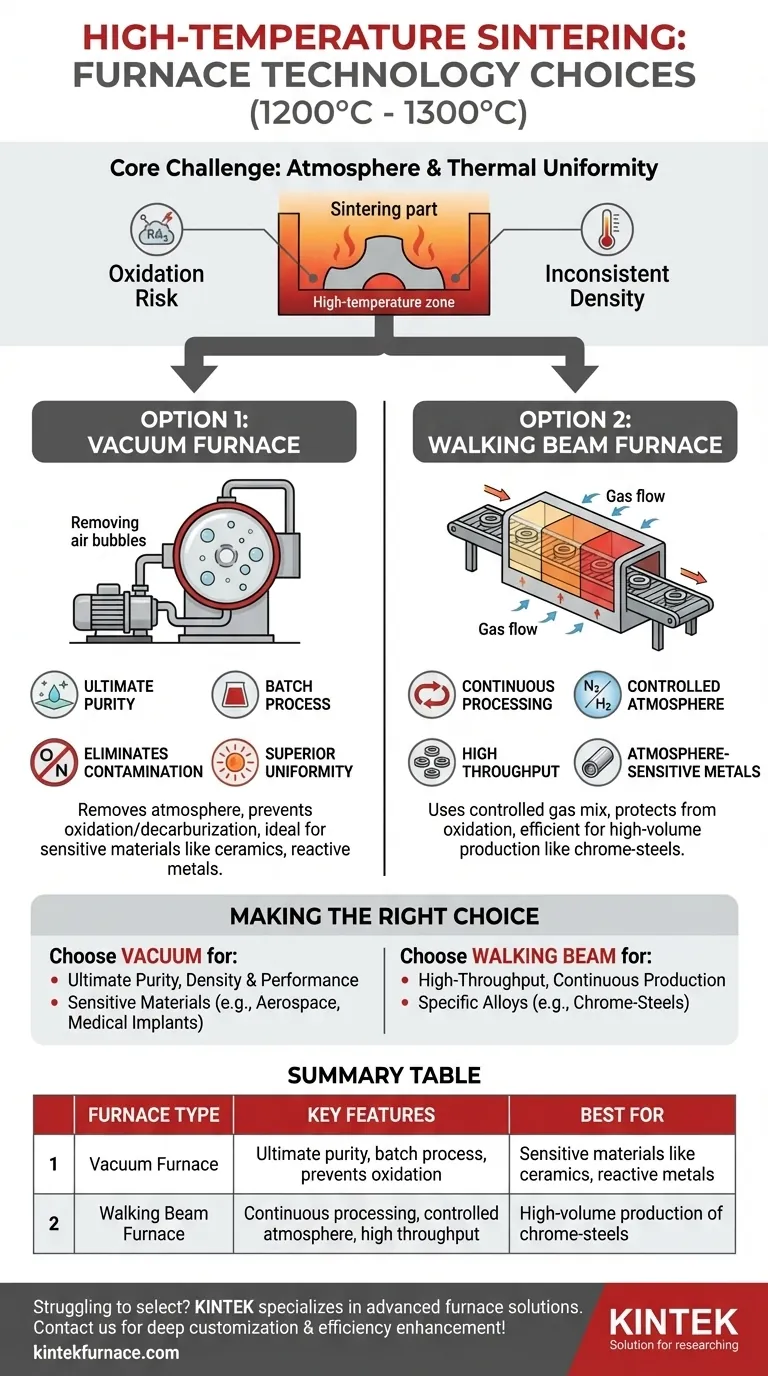

The Core Challenge: Atmosphere and Uniformity

Sintering at elevated temperatures introduces two significant process challenges. First, the risk of unwanted chemical reactions, like oxidation, increases dramatically. Second, maintaining a perfectly uniform temperature across the entire part or batch becomes more difficult, which can lead to inconsistent density and dimensional stability.

The Role of Atmospheric Control

At temperatures exceeding 1200°C, many materials become highly reactive with gases present in a standard atmosphere. Even trace amounts of oxygen can cause oxidation on the surface of metal parts, leading to discoloration, poor surface finish, and compromised mechanical properties.

For materials like ceramics or cemented carbides, trapped gases can create porosity, reducing the final density and strength of the sintered product.

The Importance of Thermal Uniformity

If one part of a component is hotter than another during sintering, it will densify at a different rate. This thermal gradient creates internal stresses, which can lead to warping, cracking, or a failure to meet dimensional tolerances. A high-quality furnace must deliver uniform heat to every surface of the part.

Option 1: The Vacuum Furnace for Ultimate Purity

A vacuum furnace operates by removing the atmosphere from the heating chamber before raising the temperature. This makes it an exceptional choice for the most sensitive and demanding sintering applications.

How It Works

By pumping out the air, a vacuum furnace creates an environment with extremely low pressure. This effectively eliminates reactive gases like oxygen and nitrogen, preventing them from interacting with the material being processed.

Key Advantage: Eliminating Contamination

This near-total removal of the atmosphere is the vacuum furnace's greatest strength. It prevents oxidation and decarburization in metals and helps extract impurity gases from ceramics and cermets. The result is a purer, denser, and higher-quality final product with superior mechanical properties and corrosion resistance.

Superior Temperature Uniformity

In a vacuum, heat is primarily transferred through radiation. This method promotes highly uniform temperature distribution throughout the chamber, ensuring consistent heating and, consequently, consistent part quality and density.

Option 2: The Walking Beam Furnace for Continuous Processing

While vacuum furnaces offer the highest purity, some industrial processes require a continuous flow of material. This is where a walking beam furnace becomes a viable alternative for specific applications.

How It Works

This furnace uses a "walking beam" mechanism to transport parts continuously through different temperature zones. It does not operate in a vacuum but instead uses a precisely controlled atmosphere, such as a specific mix of nitrogen and hydrogen, to manage the environment.

Key Advantage: Processing Atmosphere-Sensitive Metals

Walking beam furnaces are particularly well-suited for sintering materials that are sensitive to oxygen but do not require a hard vacuum, such as chrome-containing steels. The controlled atmosphere can be tailored to protect these materials from oxidation during the high-temperature cycle, making it a robust solution for high-volume production.

Understanding the Trade-offs

Choosing the right technology requires a clear understanding of the compromises between atmospheric purity, throughput, and complexity.

Atmosphere vs. Throughput

A vacuum furnace provides the purest possible environment, making it ideal for research, medical implants, aerospace components, and other critical applications. However, it is typically a batch process, which can limit overall throughput.

A walking beam furnace offers significantly higher throughput due to its continuous nature. While its atmosphere is controlled, it is not as pure as a vacuum, making it better suited for industrial production where specific, known atmospheric reactions need to be managed.

Material Sensitivity is the Deciding Factor

Your material dictates the choice. For advanced ceramics, reactive metals like titanium, or any part where absolute purity and density are non-negotiable, a vacuum furnace is the correct tool. For high-volume sintering of materials like chrome-steels where a specific protective atmosphere is sufficient, a walking beam furnace is more efficient.

Critical System Features

Regardless of the type, any modern high-temperature furnace should possess advanced control systems. Demand precise, programmable temperature controls for rapid heating and stable temperature maintenance, as well as efficient, controlled cooling systems to optimize material properties and cycle times.

Making the Right Choice for Your Process

Your decision should be guided by the final properties your component requires.

- If your primary focus is ultimate purity, density, and performance for sensitive materials: A vacuum furnace is the superior choice for eliminating atmospheric contamination.

- If your primary focus is high-throughput, continuous production of specific alloys like chrome-steels: A walking beam furnace with precise atmospheric control is the more efficient solution.

Ultimately, the most advanced furnace technology is the one that correctly matches the metallurgical or ceramic requirements of your specific material.

Summary Table:

| Furnace Type | Key Features | Best For |

|---|---|---|

| Vacuum Furnace | Ultimate purity, batch process, prevents oxidation | Sensitive materials like ceramics, reactive metals |

| Walking Beam Furnace | Continuous processing, controlled atmosphere, high throughput | High-volume production of chrome-steels |

Struggling to select the right furnace for your high-temperature sintering needs? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental requirements. Contact us today to enhance your lab's efficiency and achieve superior material performance!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process