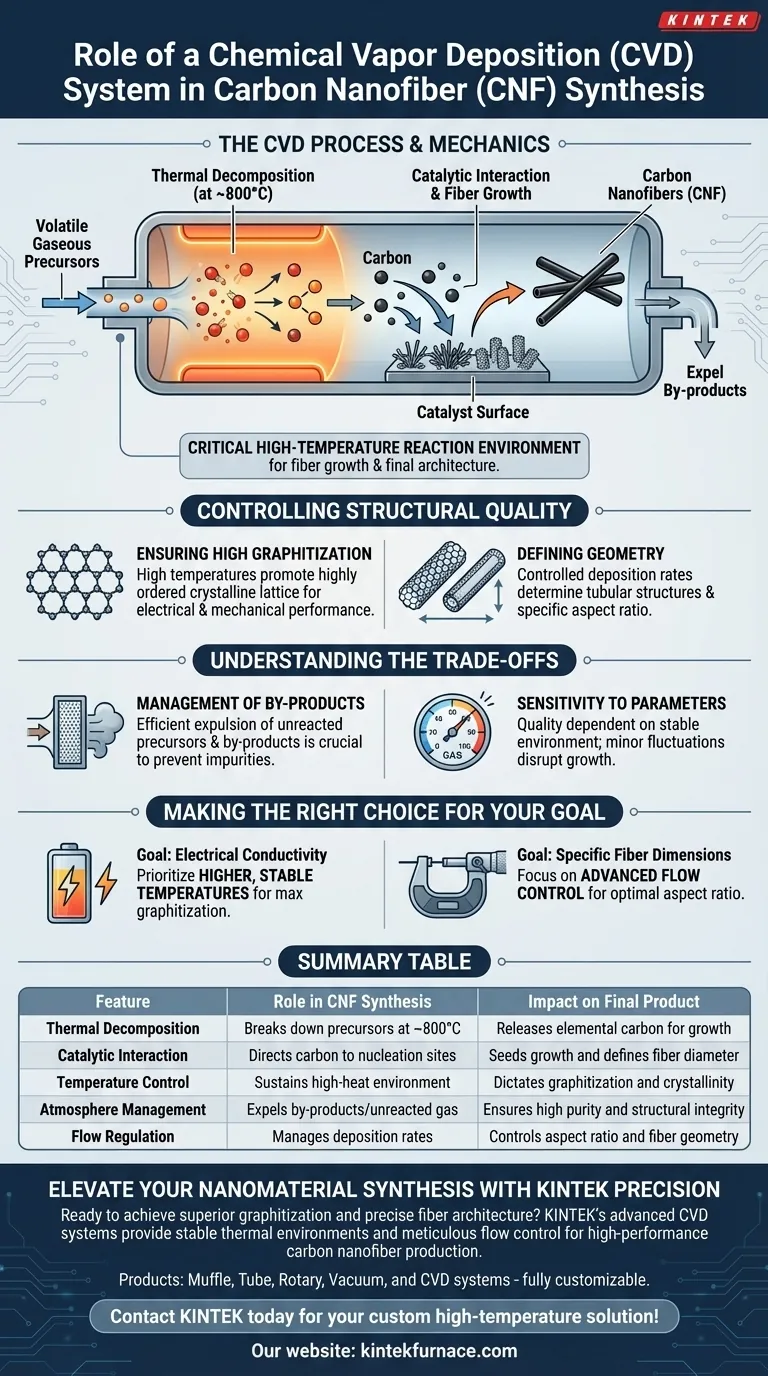

The specific role of a Chemical Vapor Deposition (CVD) system in carbon nanofiber (CNF) synthesis is to provide the critical high-temperature reaction environment required for fiber growth. It functions by introducing gaseous precursors into a chamber where they undergo thermal decomposition—typically at temperatures around 800°C—and subsequently deposit onto catalyst surfaces to form solid fibers.

The CVD system does more than just heat materials; it dictates the final architecture of the fiber. By strictly controlling the thermal decomposition process on catalyst sites, the system ensures the resulting nanofibers achieve necessary tubular structures, high degrees of graphitization, and specific aspect ratios.

The Mechanics of Deposition

Thermal Decomposition

The CVD process begins by introducing volatile gaseous precursors into the reaction chamber.

The system applies precise thermal energy, often maintaining an environment near 800°C. This heat forces the gas to break down (decompose) into its elemental carbon components.

Catalytic Interaction

The decomposed carbon atoms do not settle randomly. The system directs them to deposit onto catalyst surfaces located within the chamber.

This interaction between the carbon vapor and the solid catalyst is the nucleation point. It effectively "seeds" the growth of the nanofiber, allowing it to elongate from the substrate.

Controlling Structural Quality

Ensuring High Graphitization

The thermal environment provided by the CVD system is essential for the material's internal order.

High temperatures promote a high degree of graphitization. This means the carbon atoms arrange themselves into a highly ordered, crystalline lattice, which is crucial for the electrical and mechanical performance of the fiber.

Defining Geometry

The CVD system is responsible for the morphological characteristics of the CNF.

Through controlled deposition rates, the system enables the formation of specific tubular structures. It also determines the fiber's aspect ratio (the relationship between its length and width), which defines its suitability for different applications.

Understanding the Trade-offs

Management of By-products

The decomposition process inherently creates chemical by-products alongside the desired carbon material.

The CVD system must efficiently expel these unreacted precursors and by-products from the chamber. Failure to do so can lead to impurities or defects in the nanofiber structure.

Sensitivity to Parameters

CVD is a high-precision technique, not a bulk method.

The quality of the CNF is heavily dependent on the stability of the environment. Minor fluctuations in temperature or gas flow can disrupt nucleation kinetics, leading to inconsistent fiber growth or poor graphitization.

Making the Right Choice for Your Goal

The configuration of your CVD system should depend on the specific properties you need from the carbon nanofibers.

- If your primary focus is electrical conductivity: Prioritize a system capable of sustaining higher, stable temperatures to maximize the degree of graphitization.

- If your primary focus is specific fiber dimensions: Focus on systems with advanced flow control to precisely manage the deposition rate and achieve the optimal aspect ratio.

Success in CNF synthesis relies on viewing the CVD system not just as a furnace, but as a precision tool for molecular assembly.

Summary Table:

| Feature | Role in CNF Synthesis | Impact on Final Product |

|---|---|---|

| Thermal Decomposition | Breaks down precursors at ~800°C | Releases elemental carbon for growth |

| Catalytic Interaction | Directs carbon to nucleation sites | Seeds growth and defines fiber diameter |

| Temperature Control | Sustains high-heat environment | Dictates graphitization and crystallinity |

| Atmosphere Management | Expels by-products/unreacted gas | Ensures high purity and structural integrity |

| Flow Regulation | Manages deposition rates | Controls aspect ratio and fiber geometry |

Elevate Your Nanomaterial Synthesis with KINTEK Precision

Ready to achieve superior graphitization and precise fiber architecture? KINTEK’s advanced CVD systems are engineered to provide the stable thermal environments and meticulous flow control required for high-performance carbon nanofiber production.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory or industrial needs. Don't let process fluctuations compromise your research.

Contact KINTEK today to find your custom high-temperature solution!

Visual Guide

References

- Teguh Endah Saraswati, Wijang Wisnu Raharjo. Enhanced Performance of Epoxy Resin-Polyimide Hybrid Composites with Aminated Carbon Nanofibers Filler. DOI: 10.26554/sti.2025.10.1.152-164

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- Why is high-precision gas flow control essential for the CVD of graphene-palladium? Master Material Quality Control

- What roles do PVD and CVD play in modern thin-film technology? Key Differences and Applications Explained

- What is the difference between CVD and PVD deposition? Choose the Right Coating Technology

- What role does ultra-high vacuum PVD play in Pulsed Irradiation Synthesis? Build Pure Precursors for Metal Chalcogenides

- How are CVD furnaces utilized in the energy sector? Powering Solar and Battery Innovations

- How is argon used in Physical Vapor Deposition (PVD) processes? Enhance Coating Purity and Efficiency

- What materials are used in the hot zone of CVD furnaces? Optimize for Purity, Cost, and Performance

- What are the benefits of enhanced growth rates in CVD furnaces? Boost Throughput and Cut Costs