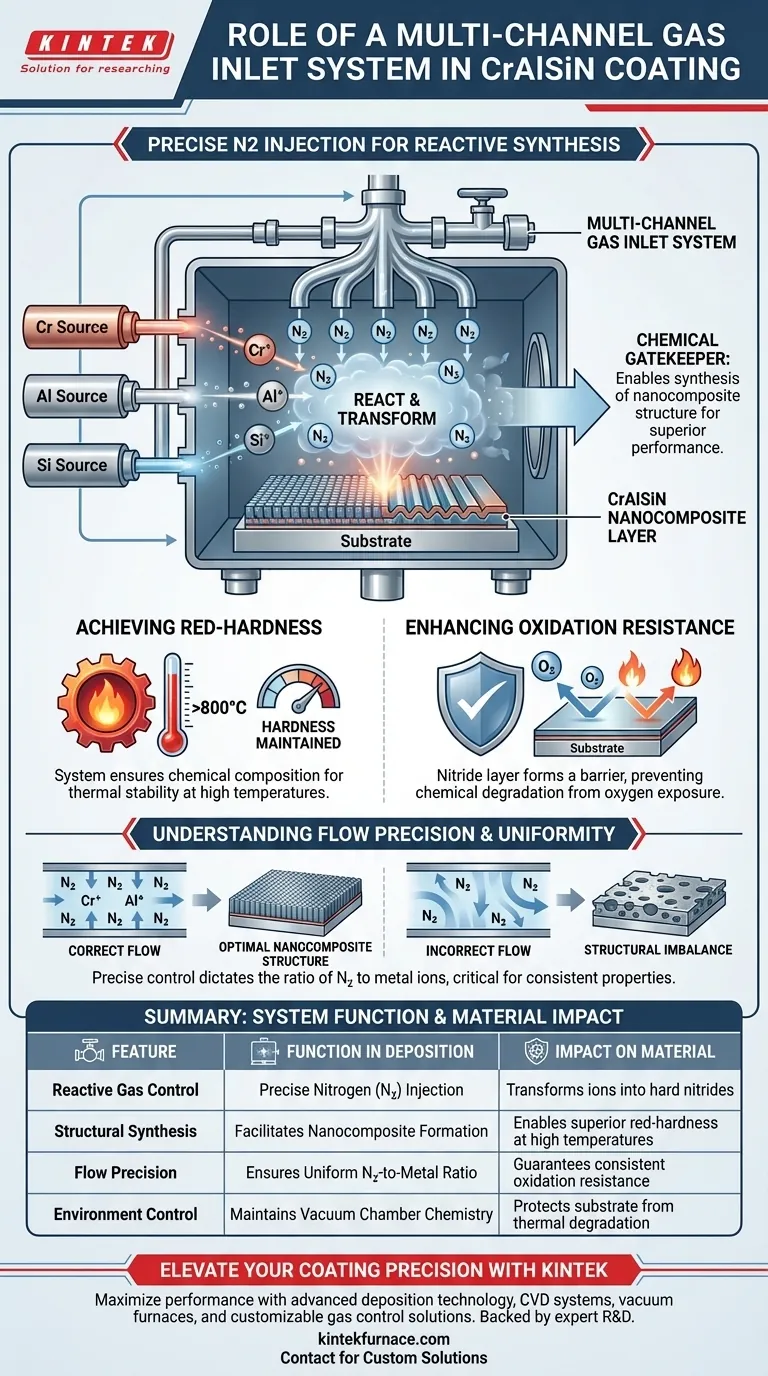

The primary role of a multi-channel gas inlet system during CrAlSiN deposition is to provide precise control over the injection of nitrogen (N2) gas into the vacuum chamber. This system ensures the reactive gas is available to combine with evaporated Chromium (Cr), Aluminum (Al), and Silicon (Si) ions, transforming simple metal ions into a complex nitride layer.

The system acts as the chemical gatekeeper of the process, enabling the synthesis of a nanocomposite structure that delivers superior red-hardness and oxidation resistance compared to standard single-layer metal films.

The Mechanics of Coating Synthesis

Facilitating the Reactive Process

The vacuum arc deposition process relies on the presence of a reactive gas to alter the properties of evaporated metals.

The multi-channel inlet introduces nitrogen specifically to act as this reactive agent. Without this controlled injection, the evaporated Cr, Al, and Si would merely deposit as a metallic mixture rather than a hard ceramic compound.

Creating a Nanocomposite Structure

The interaction between the nitrogen atoms and the metal ions is what forms the CrAlSiN layer.

This reaction does not result in a standard alloy; it creates a specific nanocomposite structure. The gas inlet system is responsible for maintaining the environment necessary to sustain this structural formation throughout the deposition cycle.

Impact on Material Properties

Achieving Red-Hardness

One of the distinct advantages of CrAlSiN coatings is their "red-hardness."

This property allows the coating to maintain its hardness even when subjected to high temperatures during operation. The gas inlet system ensures the chemical composition required for this thermal stability is consistently achieved.

Enhancing Oxidation Resistance

Beyond hardness, the coating provides a barrier against chemical degradation.

The nitride layer formed via the nitrogen injection offers significantly better oxidation resistance than single-layer metal films. This protects the underlying substrate from degrading when exposed to oxygen at high heat.

Understanding Critical Dependencies

The Importance of Flow Precision

While the primary reference highlights the benefits of the system, it is crucial to understand the dependency on flow control.

If the multi-channel system fails to deliver nitrogen uniformly, the ratio of nitrogen to metal ions will fluctuate. This imbalance prevents the correct formation of the nanocomposite structure, neutralizing the benefits of red-hardness and oxidation resistance.

Making the Right Choice for Your Application

To maximize the performance of CrAlSiN coatings, the operation of the gas inlet system must align with your specific performance targets.

- If your primary focus is high-temperature durability: Ensure the system is calibrated to maintain consistent nitrogen pressure, as this directly dictates the red-hardness of the final layer.

- If your primary focus is longevity in corrosive environments: Prioritize the uniformity of gas distribution to ensure the oxidation-resistant nitride structure is continuous across the entire surface.

The gas inlet system is not merely a supply line; it is the fundamental control mechanism that determines whether you achieve a high-performance nanocomposite or a standard metallic film.

Summary Table:

| Feature | Function in CrAlSiN Deposition | Impact on Material |

|---|---|---|

| Reactive Gas Control | Precise injection of Nitrogen (N2) | Transforms metal ions into hard nitrides |

| Structural Synthesis | Facilitates nanocomposite formation | Enables superior red-hardness at high temps |

| Flow Precision | Ensures uniform nitrogen-to-metal ratio | Guarantees consistent oxidation resistance |

| Environment Control | Maintains vacuum chamber chemistry | Protects substrate from thermal degradation |

Elevate Your Coating Precision with KINTEK

Maximize the red-hardness and oxidation resistance of your nanocomposite films with our advanced deposition technology. Backed by expert R&D and manufacturing, KINTEK offers high-performance CVD systems, vacuum furnaces, and customizable gas control solutions tailored to your unique material needs. Whether you require precise multi-channel gas flow for complex nitrides or high-temperature stability for industrial applications, our engineering team is ready to assist.

Contact KINTEK today to discuss your custom furnace and deposition requirements.

Visual Guide

References

- Sergey N. Grigoriev, Anna A. Okunkova. Increasing the Wear Resistance of Stamping Tools for Coordinate Punching of Sheet Steel Using CrAlSiN and DLC:Si Coatings. DOI: 10.3390/technologies13010030

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- How durable are CVD coatings? Unlock Extreme Durability for Your Components

- What are some applications of chemical vapor deposition? Powering Electronics, Coatings, and Sensors

- Why is an external heating belt necessary for CVD growth of 2DP-F films? Ensure Vapor Stability & Film Quality

- What are the main benefits of Chemical Vapor Deposition? Achieve Superior Film Quality and Versatility

- What is the role of Chemical Vapor Deposition (CVD) systems in manufacturing? Unlock Atomic-Level Precision for Advanced Materials

- How is argon used in Physical Vapor Deposition (PVD) processes? Enhance Coating Purity and Efficiency

- What types of materials can be deposited using CVD? Explore Versatile Thin Films for Advanced Applications

- How does precursor solution concentration affect (001) oriented TiO2 thin films? Master Precision PAD Synthesis