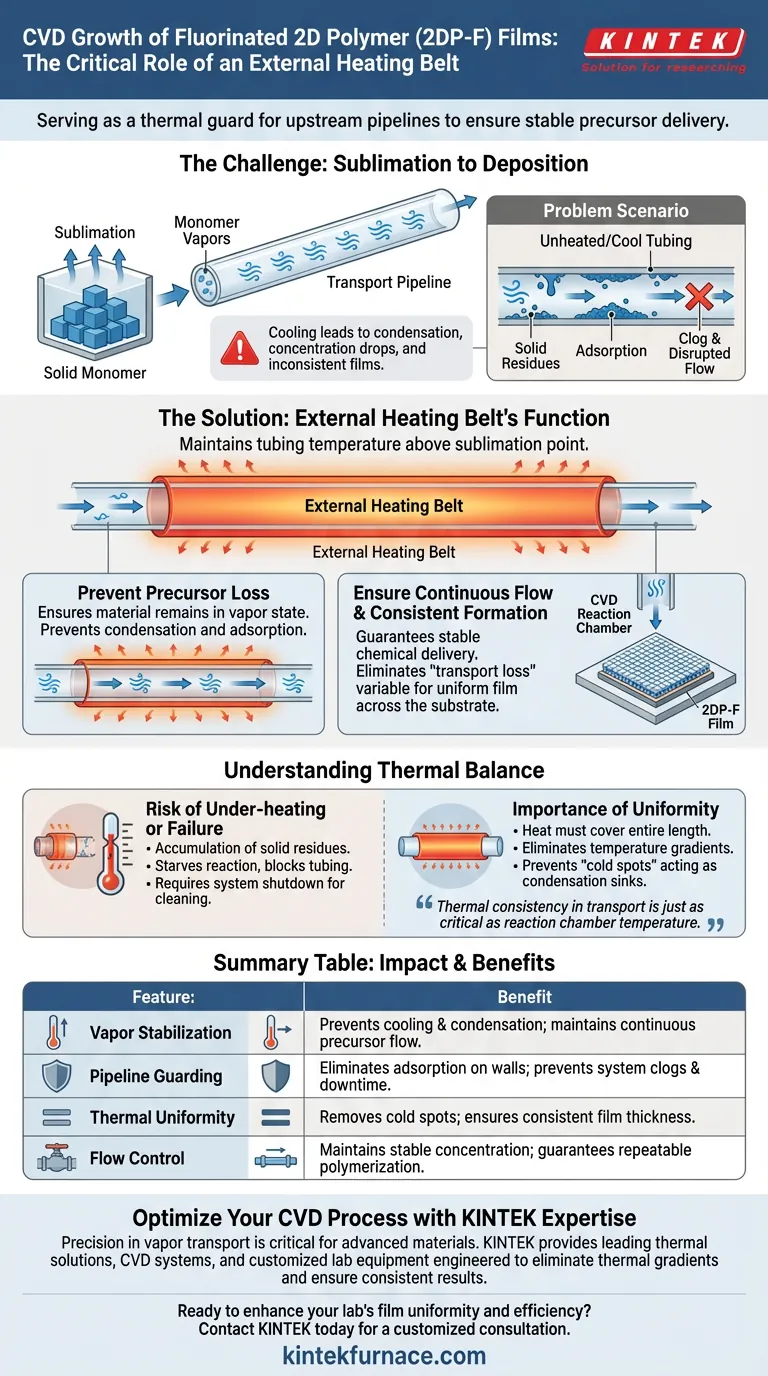

An external heating belt serves as a critical thermal guard for upstream pipelines. During the Chemical Vapor Deposition (CVD) of fluorinated two-dimensional polymer (2DP-F) films, this belt provides essential auxiliary heating. Its specific function is to prevent sublimated monomer vapors from cooling, condensing, and adsorbing onto the internal walls of transport tubing before they reach the deposition zone.

Core Insight: The integrity of a CVD process relies on stable precursor delivery. The external heating belt ensures monomers remain in a vapor state during transport, preventing clogs and concentration drops that lead to inconsistent film formation.

The Mechanics of Vapor Transport

Preventing Precursor Loss

In the CVD process for 2DP-F films, monomers are often sublimated, turning from solid directly into gas.

If these vapors travel through unheated or cool tubing, they lose thermal energy rapidly.

This cooling causes the vapors to condense and adsorb onto the inner walls of the upstream pipelines. The heating belt maintains the tubing temperature above the sublimation point, ensuring the material stays airborne.

Ensuring Continuous Flow

When vapors stick to the tubing walls, the actual amount of chemical reaching the reaction chamber drops.

This creates fluctuations in the supply of reactants.

By preventing condensation, the heating belt guarantees a continuous and stable delivery of chemical components to the substrate surface.

Achieving Consistent Film Formation

The formation of high-quality 2DP-F films requires a precise and steady supply of monomers.

Interrupted or unstable flow leads to defects, uneven thickness, or incomplete polymerization.

The heating belt eliminates the variable of "transport loss," allowing for consistent film formation across the entire substrate.

Understanding the Thermal Balance

The Risk of Under-heating

If the external heating belt is set too low or fails, the immediate result is the accumulation of solid residues in the transport lines.

This not only starves the reaction of necessary precursors but can eventually block the tubing entirely, requiring a system shutdown for cleaning.

The Importance of Uniformity

It is not enough to simply apply heat; the heat must cover the entire length of the transport line.

Any "cold spots" along the pipeline can act as condensation sinks.

Therefore, the heating belt must be applied uniformly to eliminate temperature gradients that could disrupt the vapor flow.

Making the Right Choice for Your Goal

To ensure high-quality 2DP-F growth, you must view the heating belt as an active control parameter, not just a passive accessory.

- If your primary focus is Film Uniformity: Ensure the heating belt maintains a temperature consistently above the monomer's sublimation point along the entire transport path to prevent concentration gradients.

- If your primary focus is System Maintenance: Regularly verify the heating belt's performance to prevent gradual buildup in upstream pipelines, which minimizes downtime for cleaning.

Thermal consistency in transport is just as critical as the temperature in the reaction chamber itself.

Summary Table:

| Feature | Impact on 2DP-F CVD Process | Benefit |

|---|---|---|

| Vapor Stabilization | Prevents monomers from cooling and condensing | Maintains continuous precursor flow |

| Pipeline Guarding | Eliminates adsorption on internal tubing walls | Prevents system clogs and downtime |

| Thermal Uniformity | Removes cold spots in transport lines | Ensures consistent film thickness |

| Flow Control | Maintains stable chemical concentration | Guarantees repeatable polymerization |

Optimize Your CVD Process with KINTEK Expertise

Precision in vapor transport is critical for the synthesis of advanced materials like 2DP-F films. KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing. Whether you require CVD systems, Vacuum furnaces, or customized high-temperature lab equipment, our systems are engineered to eliminate thermal gradients and ensure consistent results for your unique research needs.

Ready to enhance your lab’s film uniformity and efficiency? Contact KINTEK today for a customized consultation

Visual Guide

References

- Qiyi Fang, Jun Lou. High-performance 2D electronic devices enabled by strong and tough two-dimensional polymer with ultra-low dielectric constant. DOI: 10.1038/s41467-024-53935-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the different types of CVD systems and their applications? Choose the Right CVD for Your Lab Needs

- What are the technical advantages of using a CVD system? Optimize Carbon Nanotube Growth for Thermal Conductivity

- How does high vacuum thermal evaporation equipment contribute to Cu2SnS3 (CTS) PVD? High-Purity Film Solutions

- What role does a Rapid Thermal Processing (RTP) system play in MoS2 thin films? Achieve Precise Atomic Layer Control

- What are the key characteristics and advantages of CVD coatings? Enhance Durability and Precision for Complex Parts

- How does a CVD system ensure the quality of carbon layers? Achieving Nanometer Precision with KINTEK

- Why is CVD important in the fabrication of CMOS devices? Essential for Precise, Conformal Film Deposition

- What is the function of an infrared pyrometer in β-Ga2O3 growth? Key to Precise MOCVD Temperature Control