At its core, Chemical Vapor Deposition (CVD) provides a unique combination of advantages that distinguish it from other surface modification techniques. Its primary benefits are the ability to apply a perfectly uniform coating over highly complex geometries, create an exceptionally durable and strongly bonded layer, and allow for the precise tailoring of the coating’s material properties for a specific function.

The true value of CVD is not just in covering a surface, but in its power to fundamentally re-engineer that surface at a molecular level. This allows it to add entirely new capabilities—like extreme wear resistance or chemical inertness—to components of almost any shape.

The Defining Advantage: Conformal Coating on Any Geometry

The most significant characteristic of CVD is its ability to coat surfaces uniformly, regardless of their complexity. This stems from the fact that the coating is formed from a gas phase, not a line-of-sight spray or bath.

Beyond Line-of-Sight Deposition

The precursor gases in a CVD process flow and diffuse to envelop the entire part. This means that internal channels, threaded holes, and intricate features receive the same high-quality coating as exposed, flat surfaces.

Uniformity Across Complex Surfaces

CVD ensures a consistent coating thickness across the entire component. This "wrap-around" effect is critical for parts with complex shapes, where even slight variations in coating thickness could lead to performance failures.

Eliminating Weak Points

By completely and uniformly covering the substrate, CVD avoids exposed areas that could become reactive sites for corrosion or wear. This creates a truly sealed and protected surface.

Building a Foundation of Extreme Durability

CVD coatings are not simply "stuck on" the surface; they are chemically integrated with it. This results in superior adhesion and resilience in demanding environments.

The Power of the Diffusion Bond

The high temperatures involved in many CVD processes promote diffusion between the coating and the substrate material. This creates a metallurgical bond that is exceptionally strong and far more robust than a purely mechanical one.

Resilience in Harsh Environments

This strong bond, combined with the dense and stable nature of the deposited film, gives CVD coatings the ability to withstand extreme temperatures, rapid thermal cycling, and significant mechanical stress without delaminating.

High Load-Bearing Capacity

Because the coating is intrinsically part of the surface, it has a high load-bearing capacity. The low residual stress in the film also means it is less prone to cracking or flaking under pressure.

Tailoring Material Properties at the Molecular Level

CVD is not a single process but a versatile platform that allows for precise control over the final coating's characteristics.

Achieving Unmatched Purity

The process uses highly pure precursor gases and a controlled environment, resulting in films with exceptionally high purity and a well-defined crystalline structure.

Customizing for a Specific Function

By changing the precursor gases and process parameters, the coating can be optimized for a specific goal. This includes enhancing wear resistance, creating a chemically inert barrier, providing lubricity, or blocking corrosion.

Precise Control Over Thickness

The deposition rate in CVD is highly controllable, allowing for precise management of the final coating thickness, which is critical for components with tight engineering tolerances.

Understanding the Trade-offs and Considerations

While powerful, the characteristics of the CVD process introduce practical considerations that must be weighed against its benefits.

The High-Temperature Requirement

Traditional CVD processes operate at very high temperatures. This can limit the types of substrate materials that can be coated, as the material must be able to withstand the heat without deforming or undergoing undesirable metallurgical changes.

Precursor Chemistry and Handling

The gases used as precursors in CVD can be toxic, flammable, or corrosive. This necessitates specialized handling equipment and safety protocols, which can impact the operational complexity and cost.

Process vs. Part Complexity

While CVD excels at coating complex parts, the process itself can be more intricate to set up and control than simpler methods like electroplating or painting. Its value is highest when the performance requirements justify the investment.

Making the Right Choice for Your Application

Selecting the right coating technology depends entirely on your primary engineering goal.

- If your primary focus is coating complex internal geometries: CVD is often the superior choice due to its non-line-of-sight, gas-phase deposition that ensures complete coverage.

- If your primary focus is extreme durability and adhesion: The diffusion bond created by high-temperature CVD offers unmatched performance for high-stress and high-temperature environments.

- If your primary focus is high purity or specific chemical properties: CVD provides the molecular-level control needed for demanding applications in semiconductors, medical devices, or chemical processing.

- If your primary focus is coating a temperature-sensitive material: You must either ensure the substrate can withstand the process or explore lower-temperature CVD variants (like PECVD).

Ultimately, understanding these core principles empowers you to determine if CVD's unique capabilities align with your component's performance demands.

Summary Table:

| Characteristic | Advantage |

|---|---|

| Conformal Coating | Uniform coverage on complex geometries, including internal features |

| Strong Adhesion | Diffusion bond for extreme durability and resilience in harsh environments |

| Tailored Properties | Precise control over material characteristics like wear resistance and chemical inertness |

| High Purity | Exceptional purity and well-defined crystalline structure from controlled processes |

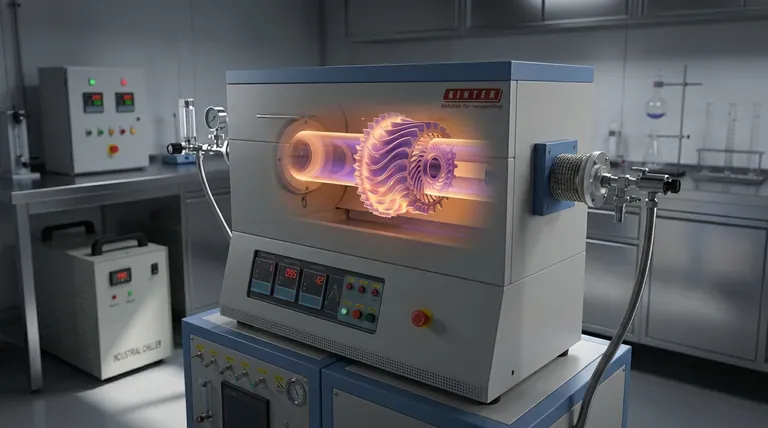

Ready to elevate your component performance with advanced CVD coatings? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how we can help you achieve superior surface engineering results!

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- What are the advantages of CVD tube furnace sintering systems? Achieve Superior Material Control and Purity

- What customization options are available for CVD tube furnaces? Tailor Your System for Superior Material Synthesis

- What are the operational benefits of using a CVD Tube Furnace? Enhance Precision and Efficiency in Your Lab

- What are the key features of CVD tube furnaces for 2D material processing? Unlock Precision Synthesis for Superior Materials