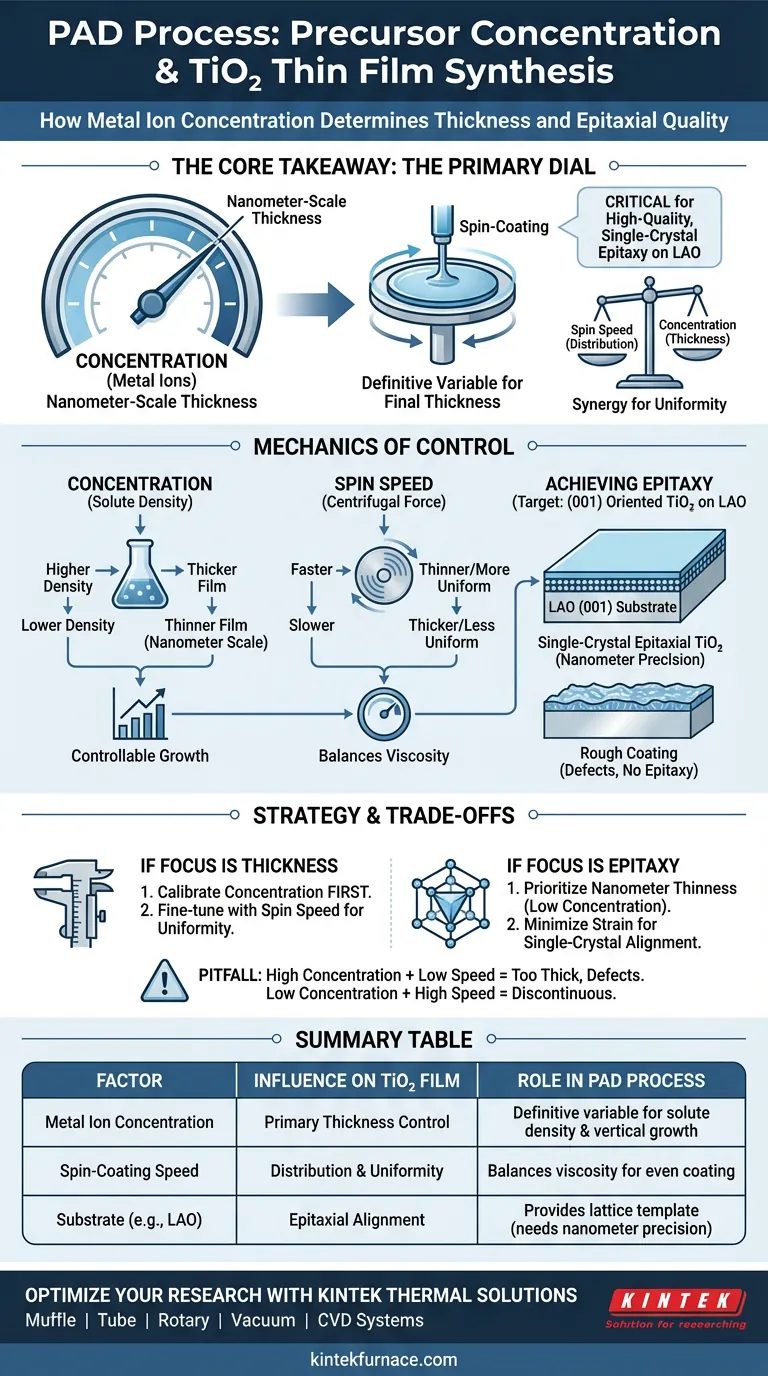

In the Polymer-Assisted Deposition (PAD) process, the concentration of metal ions in the precursor solution is the definitive variable for determining the thickness of the final TiO2 film. This concentration does not act in isolation; it functions as a primary dial that, when calibrated, dictates the volume of material deposited. By manipulating this concentration, you directly influence the structural integrity and epitaxial quality of the resulting thin film.

Core Takeaway While spin-coating speed influences distribution, the concentration of metal ions is the critical factor for achieving precise, nanometer-scale thickness control. This precision is a prerequisite for forming high-quality, single-crystal epitaxial structures on substrates like LaAlO3 (LAO).

The Mechanics of Thickness Control

The Role of Metal Ion Concentration

The fundamental lever for controlling film growth in PAD is the concentration of metal ions within your precursor solution.

Unlike methods where thickness is determined primarily by deposition time, PAD relies on the solute density to define the final vertical dimension.

By precisely adjusting this concentration, you move from arbitrary deposition to controllable growth at the nanometer scale.

The Synergy with Spin Speed

Concentration cannot be viewed in a vacuum; it works in strict conjunction with spin-coating speed.

To achieve a specific target thickness, you must balance the viscosity (driven by concentration) against the centrifugal force (driven by spin speed).

Mastering this relationship is necessary to ensure a uniform coating prior to thermal treatment.

Achieving High-Quality Epitaxy

Facilitating Single-Crystal Growth

The ultimate goal of controlling concentration is to enable the formation of high-quality single-crystal epitaxial structures.

The reference explicitly notes that this control is required for success on specific substrates, such as LaAlO3 (LAO).

Without precise thickness control via concentration, the film may fail to align epitaxially with the (001) substrate lattice.

Nanometer-Scale Precision

The PAD process allows for film engineering at the nanometer level.

This level of precision is critical for advanced applications where bulk properties must be avoided in favor of thin-film characteristics.

Concentration is the tool that grants you access to this scale of fabrication.

Understanding the Trade-offs

The Multi-Variable Balancing Act

A common pitfall in PAD is adjusting concentration without compensating for spin speed.

High concentrations at low speeds may result in films that are too thick to maintain epitaxial stress, potentially leading to defects.

Conversely, low concentrations at high speeds may yield discontinuous films that lack the necessary coverage for functional devices.

Substrate Dependency

While the process is effective for substrates like LAO, the concentration parameters are system-specific.

A concentration that yields perfect epitaxy on LAO may behave differently on a substrate with a different lattice constant or surface energy.

You must treat the concentration value as relative to your specific substrate-precursor pairing.

Making the Right Choice for Your Goal

To maximize the quality of your (001) oriented TiO2 films, consider the following approach:

- If your primary focus is Film Thickness: Calibrate your metal ion concentration first, then fine-tune uniformity using spin speed.

- If your primary focus is Epitaxial Quality: Prioritize a concentration that yields nanometer-scale thinness to minimize strain and ensure single-crystal alignment on the LAO substrate.

Precision in precursor concentration is the difference between a rough coating and a device-grade epitaxial film.

Summary Table:

| Factor | Influence on TiO2 Film | Role in PAD Process |

|---|---|---|

| Metal Ion Concentration | Primary Thickness Control | Definitive variable for solute density and vertical growth |

| Spin-Coating Speed | Distribution & Uniformity | Balances viscosity to ensure even coating before thermal treatment |

| Substrate (e.g., LAO) | Epitaxial Alignment | Provides lattice template; requires nanometer-scale precision |

| Precision Level | Nanometer-Scale | Essential for high-quality single-crystal structures |

Optimize Your Thin Film Research with KINTEK

Precision in precursor concentration requires high-performance thermal processing to achieve device-grade epitaxy. Backed by expert R&D and manufacturing, KINTEK offers high-temperature Muffle, Tube, Rotary, Vacuum, and CVD systems designed to support sophisticated methods like Polymer-Assisted Deposition. Whether you are working with TiO2 on LAO or developing custom epitaxial structures, our systems are fully customizable to meet your unique laboratory needs.

Ready to elevate your material synthesis? Contact our technical experts today to find the perfect thermal solution for your research.

Visual Guide

References

- Tianyao Zhang, Yuan Lin. Highly Sensitive Wearable Sensor Based on (001)‐Orientated TiO<sub>2</sub> for Real‐Time Electrochemical Detection of Dopamine, Tyrosine, and Paracetamol. DOI: 10.1002/smll.202312238

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the steps of chemical vapor deposition? Master the Process for Superior Thin Films

- What is a CVD Tube Furnace and what is its primary purpose? Unlock Precision Thin Film Deposition

- What are the advantages of inside-out processing in CVD? Unlock Complex, Net-Shape Fabrication

- What role does iodine (I2) play as a transport agent in the synthesis of 1T-TaS2 single crystals? CVT Mechanism Explained

- How does the CVD process work in depositing materials onto substrates? Master Thin-Film Deposition for Superior Materials

- What is the temperature range for chemical vapor deposition? From 200°C to 900°C for Precise Thin Films

- What role do catalysts play in graphene production? Unlock Efficient, High-Quality Synthesis

- How does the environment inside a CVD furnace contribute to material synthesis? Achieve Atomic Precision in Material Engineering