At its core, a CVD Tube Furnace is a highly specialized piece of laboratory equipment that combines a high-temperature furnace with a sealed process tube. Its primary purpose is to create an extremely precise and controlled environment of temperature and atmosphere, which is necessary for the process of Chemical Vapor Deposition (CVD) to occur. This allows scientists and engineers to grow high-quality, high-performance solid materials and thin films on a substrate.

The critical takeaway is that a CVD tube furnace is not just a high-temperature oven. It is a complete reactor system designed to precisely control the conditions for a chemical reaction that transforms gases into solid thin films, enabling the creation of advanced materials.

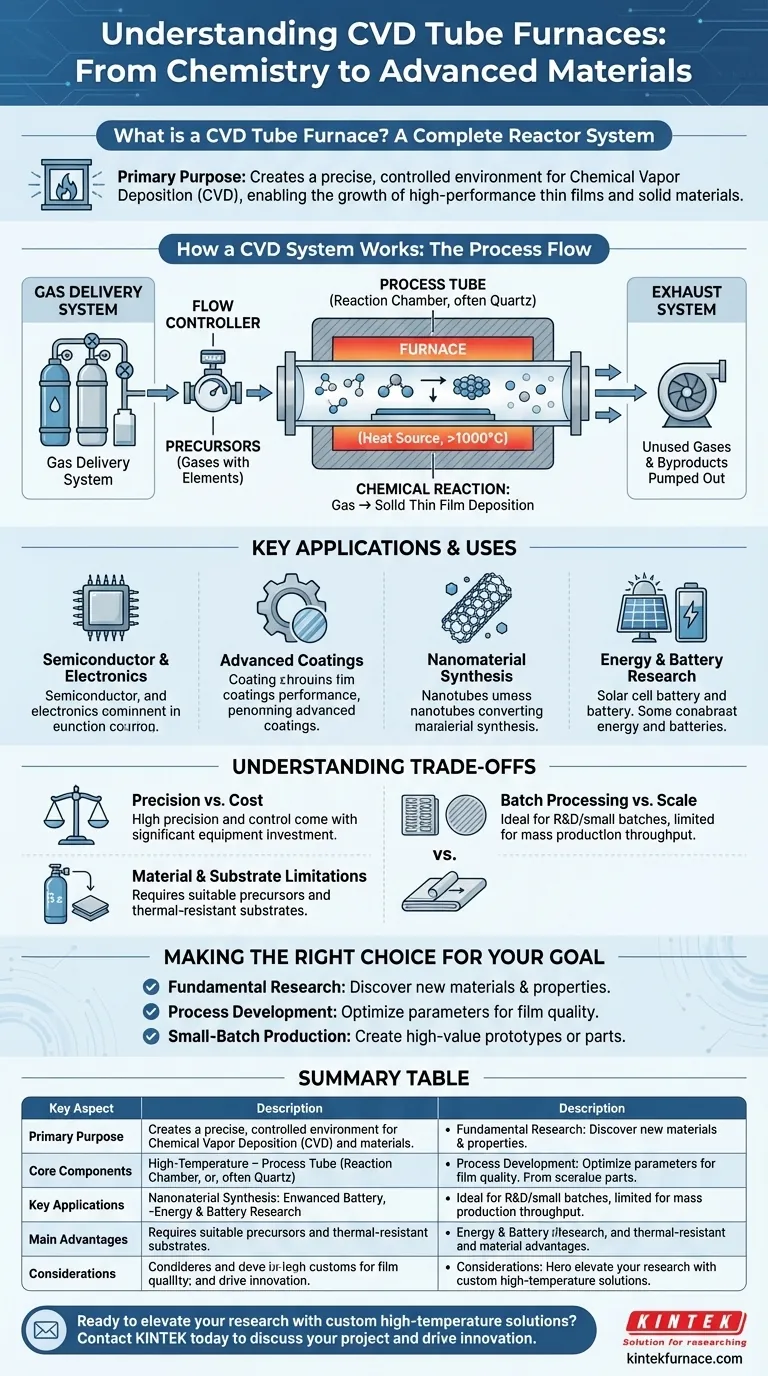

How a CVD System Works

To understand the furnace, you must first understand the process it enables. The system is an assembly of components working together to facilitate a precise chemical reaction.

The Furnace: The Heat Source

The furnace itself is the outer heating chamber. It uses robust heating elements to generate and maintain very high, uniform temperatures, often exceeding 1000°C.

This temperature stability is critical, as the chemical reactions in CVD are highly sensitive to thermal fluctuations.

The Process Tube: The Reaction Chamber

At the heart of the furnace is a long, sealed tube, typically made of quartz, alumina, or another inert material. The sample, or substrate, on which the film will be grown is placed inside this tube.

Quartz is often preferred because it is chemically inert at high temperatures and transparent, allowing researchers to visually monitor the process.

The Gas Delivery System: The Precursors

A sophisticated system of pipes, valves, and mass flow controllers is connected to the tube. This system precisely introduces one or more gases, known as precursors, into the sealed environment.

These precursors contain the chemical elements that will make up the final deposited film.

The Chemical Reaction: From Gas to Solid

Inside the hot zone of the tube, the high temperature provides the energy for the precursor gases to react. This chemical reaction causes a solid material to form and deposit as a thin, uniform layer—a thin film—onto the surface of the substrate.

Unused gases and reaction byproducts are then safely pumped out through an exhaust system.

Key Applications and Uses

The ability to create high-purity, high-performance thin films makes CVD tube furnaces essential in many advanced fields.

Semiconductor and Electronics

CVD is a cornerstone of the semiconductor industry. It is used to deposit the various layers of insulating, conducting, and semiconducting materials that form integrated circuits.

Advanced Coatings

The process creates extremely hard and durable coatings for cutting tools, wear-resistant coatings for mechanical parts, and anti-reflective or protective coatings for optics.

Nanomaterial Synthesis

In research settings, these furnaces are used to grow one-dimensional nanomaterials like nanowires and nanotubes or two-dimensional materials like graphene.

Energy and Battery Research

Researchers use CVD furnaces to develop new materials for solar cells, fuel cells, and high-performance battery electrodes, optimizing their efficiency and lifespan.

Understanding the Trade-offs

While powerful, the CVD process and the equipment it requires involve important considerations and limitations.

Precision vs. Cost

CVD tube furnaces offer unparalleled control over temperature, pressure, and gas flow. This precision comes at a significant cost, making the equipment a major investment for any lab.

Batch Processing vs. Scale

A traditional tube furnace is fundamentally a batch process, meaning it can only process a limited number of substrates at a time. While ideal for research and development, this limits its throughput for mass production.

Material and Substrate Limitations

The CVD process is dependent on the availability of suitable precursor gases that are stable at room temperature but reactive at high temperatures. Furthermore, the substrate material must be able to withstand the high process temperatures without degrading.

Making the Right Choice for Your Goal

The application of a CVD tube furnace depends entirely on your objective, from fundamental discovery to product development.

- If your primary focus is fundamental research: The furnace's precise control over process variables is essential for experimenting with and discovering new materials and properties.

- If your primary focus is process development: This equipment is perfect for optimizing deposition parameters to achieve a specific film quality, thickness, and performance for a new product.

- If your primary focus is small-batch production: A CVD tube furnace can be used to create high-value components, prototypes, or specialized coated parts where quality outweighs quantity.

Ultimately, the CVD tube furnace is a critical tool that bridges the gap between chemical theory and tangible, high-performance materials.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Purpose | To create a controlled environment for Chemical Vapor Deposition (CVD), enabling growth of solid materials and thin films on substrates. |

| Core Components | Furnace (heat source), Process tube (reaction chamber), Gas delivery system (precursors), Exhaust system. |

| Key Applications | Semiconductor manufacturing, Advanced coatings, Nanomaterial synthesis, Energy and battery research. |

| Main Advantages | Precise temperature and atmosphere control, high-quality film deposition, versatility in material synthesis. |

| Considerations | High cost, batch processing limits throughput, dependency on precursor gases and substrate compatibility. |

Ready to elevate your materials research with a custom CVD tube furnace? KINTEK specializes in advanced high-temperature solutions, including Tube Furnaces and CVD/PECVD Systems, backed by exceptional R&D and in-house manufacturing for deep customization. Whether you're in semiconductors, nanomaterials, or energy research, we'll tailor a furnace to meet your unique experimental needs. Contact us today to discuss your project and discover how our expertise can drive your innovations forward!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- What role do CVD tube furnace sintering systems play in 2D material synthesis? Enabling High-Quality Atomic Layer Growth

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What temperature ranges can a CVD Tube Furnace achieve with different tube materials? Unlock High-Temp Precision for Your Lab