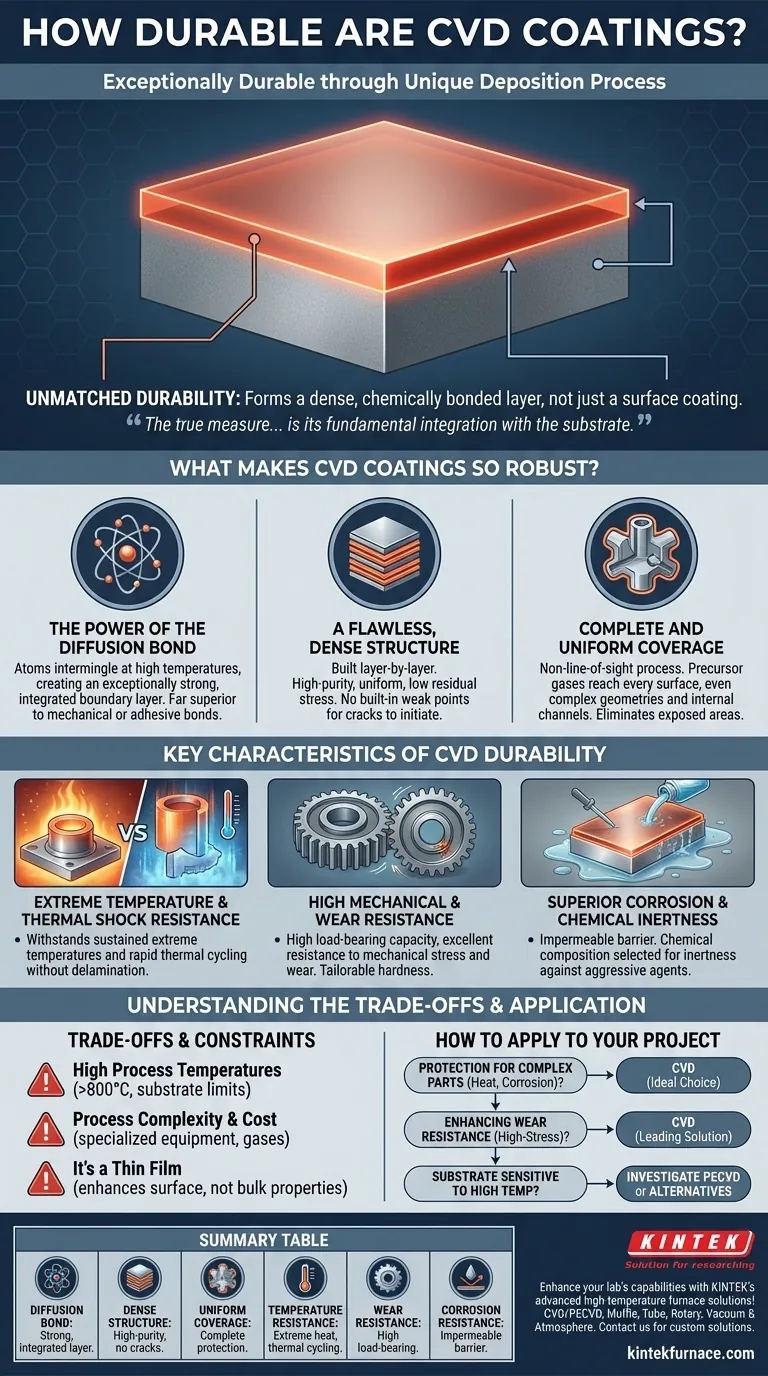

In short, CVD coatings are exceptionally durable. This durability stems from the unique deposition process itself, which forms a dense, uniform, and chemically bonded layer on a substrate's surface. As a result, these coatings can withstand extreme temperatures, high mechanical stress, and harsh chemical environments where other surface treatments would fail.

The true measure of a CVD coating's durability is not just its hardness, but its fundamental integration with the substrate. The process creates a diffusion bond, meaning the coating and the part become a single, unified material at their interface, providing unmatched adhesion and resilience.

What Makes CVD Coatings So Robust?

The remarkable durability of Chemical Vapor Deposition (CVD) coatings is not a single characteristic but the result of several interconnected properties inherent to the process. Understanding these factors is key to appreciating their performance.

The Power of the Diffusion Bond

Unlike paints or platings that simply sit on a surface, CVD coatings are formed through a chemical reaction that creates a diffusion bond.

At the high temperatures of the CVD process, atoms from the coating material and the substrate intermingle. This creates an exceptionally strong, integrated boundary layer that is far more robust than a purely mechanical or adhesive bond.

A Flawless, Dense Structure

The CVD process builds the coating layer by layer, resulting in a film that is high-purity, dense, and uniform.

This method produces materials with low residual stress and good crystallinity. The absence of voids or internal stresses means there are no built-in weak points where cracks or failures can initiate under load.

Complete and Uniform Coverage

CVD is a non-line-of-sight process, meaning the precursor gases can reach every exposed surface of a component.

This ensures complete and uniform coverage, even on parts with complex geometries, sharp corners, or internal channels. By eliminating exposed substrate areas, the coating provides total protection without creating weak points or reactive sites.

Key Characteristics of CVD Durability

The underlying structural advantages of CVD manifest as specific, measurable performance benefits in demanding applications.

Extreme Temperature and Thermal Shock Resistance

CVD coatings are engineered to perform in high-heat environments. Because the coating is chemically bonded to the substrate, it can withstand both extreme sustained temperatures and rapid thermal cycling without delaminating or failing.

High Mechanical and Wear Resistance

The dense, uniform structure of a CVD film gives it a high load-bearing capacity and excellent resistance to mechanical stress and wear. The properties of the coating, such as hardness and lubricity, can be tailored for specific wear-resistance applications.

Superior Corrosion and Chemical Inertness

Because the coating provides complete, pinhole-free coverage, it creates an impermeable barrier between the substrate and its environment. The chemical composition of the coating can be selected to provide chemical inertness, protecting the part from aggressive and corrosive agents.

Understanding the Trade-offs

While exceptionally effective, CVD is not a universal solution. An objective assessment requires understanding its operational constraints.

High Process Temperatures

Traditional CVD processes require very high temperatures, often in excess of 800°C. This can limit the types of substrate materials that are compatible, as the process could temper, anneal, or otherwise alter the substrate's fundamental properties.

Process Complexity and Cost

CVD is a sophisticated process that requires specialized vacuum equipment and the handling of potentially hazardous precursor gases. This complexity can translate to higher costs and longer lead times compared to simpler coating methods.

It's a Thin Film, Not Bulk Material

CVD coatings are typically very thin, ranging from hundreds of nanometers to around 20 micrometers. While incredibly durable for their thickness, they enhance a substrate's surface properties; they do not change its bulk characteristics like strength or rigidity.

How to Apply This to Your Project

Your choice depends entirely on your application's specific demands and the nature of your substrate material.

- If your primary focus is protecting complex parts from extreme heat or corrosion: CVD is an ideal choice due to its uniform, non-line-of-sight coverage and exceptionally strong bond.

- If your primary focus is enhancing wear resistance on a high-stress component: The dense, low-stress structure and high load-bearing capacity of CVD make it a leading solution.

- If your substrate is sensitive to high temperatures: You must confirm that your material can withstand the process or investigate lower-temperature CVD variants like Plasma-Enhanced CVD (PECVD).

By understanding both the profound advantages and the practical limitations of CVD, you can make a truly informed decision for your specific engineering challenge.

Summary Table:

| Characteristic | Description |

|---|---|

| Diffusion Bond | Creates a strong, integrated layer with the substrate for unmatched adhesion. |

| Dense Structure | High-purity, uniform coating with low residual stress to prevent cracks. |

| Uniform Coverage | Non-line-of-sight process ensures complete protection on complex geometries. |

| Temperature Resistance | Withstands extreme heat and thermal cycling without delamination. |

| Wear Resistance | High load-bearing capacity and tailored hardness for mechanical stress. |

| Corrosion Resistance | Impermeable barrier providing chemical inertness in harsh environments. |

Enhance your lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with CVD/PECVD systems and other furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere models. Our strong deep customization capability ensures we precisely meet your unique experimental needs for durable coatings. Contact us today to discuss how we can optimize your projects with reliable, high-performance equipment!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- What is PECVD specification? A Guide to Choosing the Right System for Your Lab