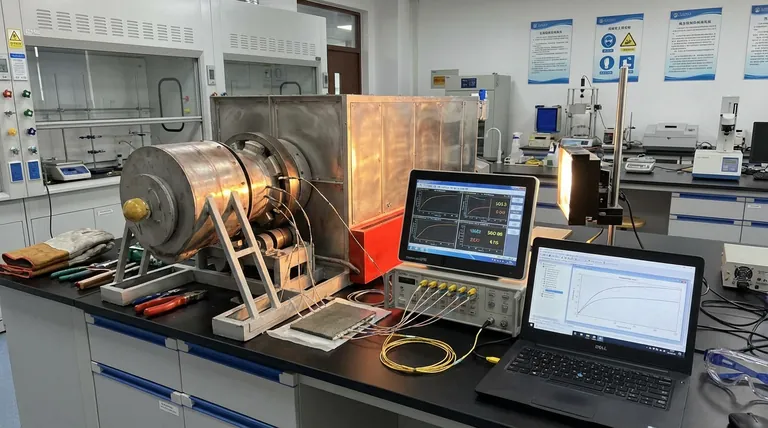

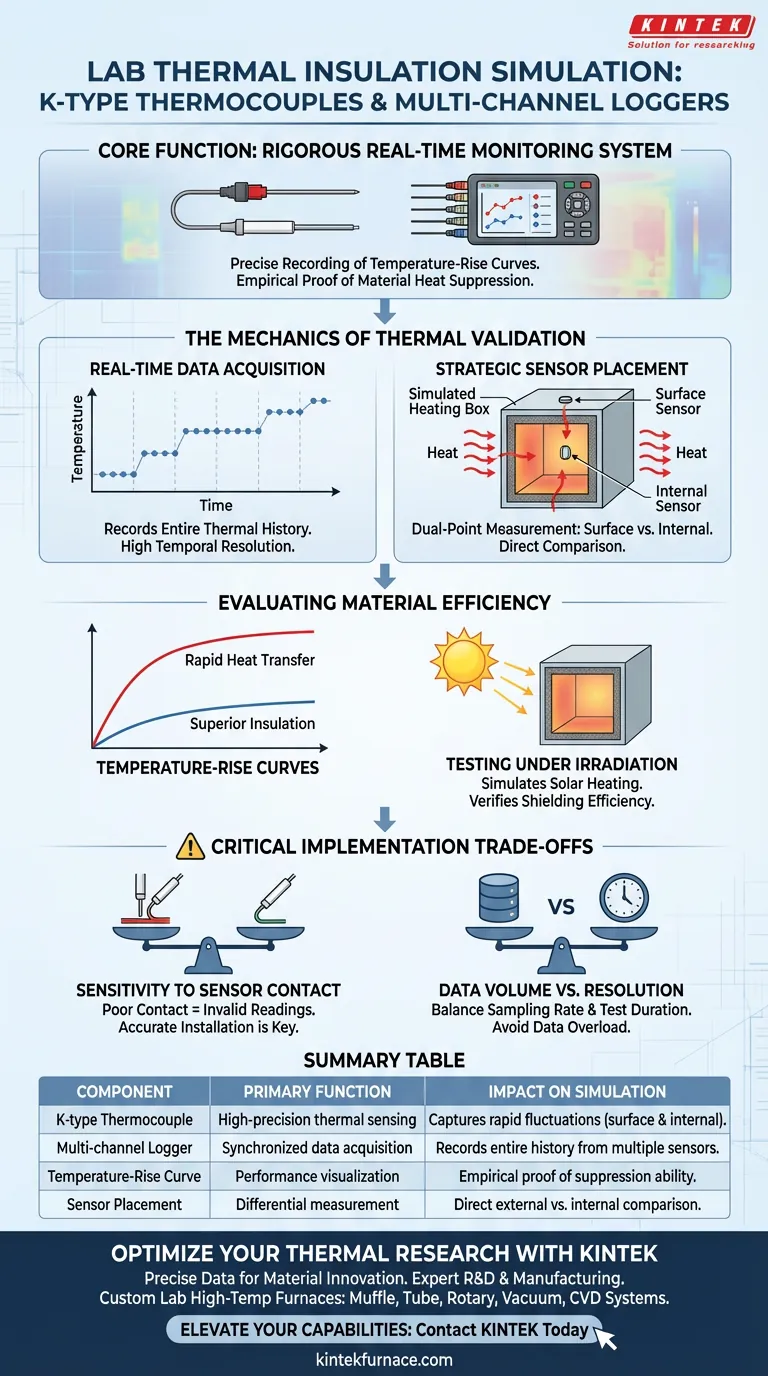

The primary function of K-type thermocouples and multi-channel loggers is to establish a rigorous, real-time thermal monitoring system. In laboratory settings, specifically when testing materials like GFPP composites, this setup records precise temperature-rise curves. By monitoring both the internal and surface temperatures of a simulated heating box, the system provides empirical proof of a material's ability to suppress heat buildup under intense light irradiation.

By capturing high-resolution data over time, this system transforms abstract material properties into visible performance metrics. It allows researchers to quantify exactly how effectively an insulation barrier prevents external heat from penetrating a protected volume.

The Mechanics of Thermal Validation

Real-Time Data Acquisition

The core value of combining K-type thermocouples with a multi-channel logger is the ability to track thermal changes as they happen.

Rather than relying on static measurements before and after a test, this system records the entire thermal history. This ensures that the rate of temperature change is captured with high temporal resolution.

Strategic Sensor Placement

To accurately evaluate insulation, data must be collected from multiple specific locations simultaneously.

The standard protocol involves positioning sensors both inside the simulated heating box and on the surface of the material. This dual-point measurement allows for a direct comparison between the heat source intensity and the internal environment.

Evaluating Material Efficiency

Visualizing Performance with Curves

The raw data collected by the logger is used to generate temperature-rise curves.

These curves are the definitive evidence of performance. A flatter curve for the internal sensor indicates superior insulation, while a steep curve suggests rapid heat transfer.

Testing Under Irradiation

This monitoring setup is specifically designed to validate materials under stress, such as intense light irradiation.

By subjecting the heating box to high-intensity light, the system simulates real-world solar heating. The logger then verifies the actual efficiency of the composite material in shielding the internal space from this external energy source.

Critical Implementation Trade-offs

Sensitivity to Sensor Contact

The accuracy of the temperature-rise curve is heavily dependent on the physical installation of the thermocouples.

If a surface sensor does not have perfect thermal contact with the composite, the logger will record air temperature rather than material temperature. This leads to understated surface heat readings and invalid efficiency calculations.

Data Volume vs. Resolution

While high temporal resolution is desired, it requires capable logging hardware to handle the data influx.

Users must balance the sampling rate with the duration of the test. Extremely high sampling rates over long irradiation periods can overwhelm storage or complicate data processing without adding significant value to the trend analysis.

How to Apply This to Your Project

If your primary focus is material validation: Ensure your sensors are placed to capture the differential between the exposed surface and the protected internal volume to prove suppression efficiency.

If your primary focus is detailed thermal analysis: Prioritize the temporal resolution of your multi-channel logger to capture minute fluctuations in the temperature-rise curve during the initial phases of irradiation.

The ultimate goal of this setup is to move beyond theoretical insulation values and provide a direct, data-driven demonstration of how a material performs under thermal stress.

Summary Table:

| Component | Primary Function | Impact on Simulation |

|---|---|---|

| K-type Thermocouple | High-precision thermal sensing | Captures rapid temperature fluctuations at surface and internal points. |

| Multi-channel Logger | Synchronized data acquisition | Records the entire thermal history from multiple sensors simultaneously. |

| Temperature-Rise Curve | Performance visualization | Provides empirical proof of a material's ability to suppress heat buildup. |

| Sensor Placement | Differential measurement | Allows direct comparison between external intensity and internal protection. |

Optimize Your Thermal Research with KINTEK

Precise data is the backbone of material innovation. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-performance thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are simulating intense solar irradiation or testing advanced GFPP composites, our lab high-temp furnaces are fully customizable to meet your unique research needs.

Ready to elevate your laboratory's thermal validation capabilities?

Contact KINTEK Today to Discuss Your Custom Project

Visual Guide

References

- Glass Fiber-Reinforced Polypropylene Composites with High Solar Reflectance for Thermal Insulation Applications. DOI: 10.3390/polym17030274

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is MoSi2 heating element? A Guide to Extreme-Temperature Stability Up to 1800°C

- Why use silicon molybdenum rod furnaces for desulfurizer homogenization? Achieving 1400°C Thermal Stability

- How is infrared energy directed in a quartz heater? Uncover the Science Behind Efficient, Targeted Warmth

- What are the advantages of quartz tubes in terms of durability and maintenance? Enhance Lab Efficiency with Low-Maintenance Solutions

- What are silicon carbide (SiC) heating elements made of? A Guide to Extreme-Temperature Performance

- What is the purpose of using K-type thermocouples and high-temperature sealants? Ensure Precision in Gas Heating Systems

- What are the key properties of Silicon Carbide (SiC) that make it suitable for heating elements? Unlock High-Temp Performance

- Can a faulty ceramic heater be repaired? Key Factors & Solutions