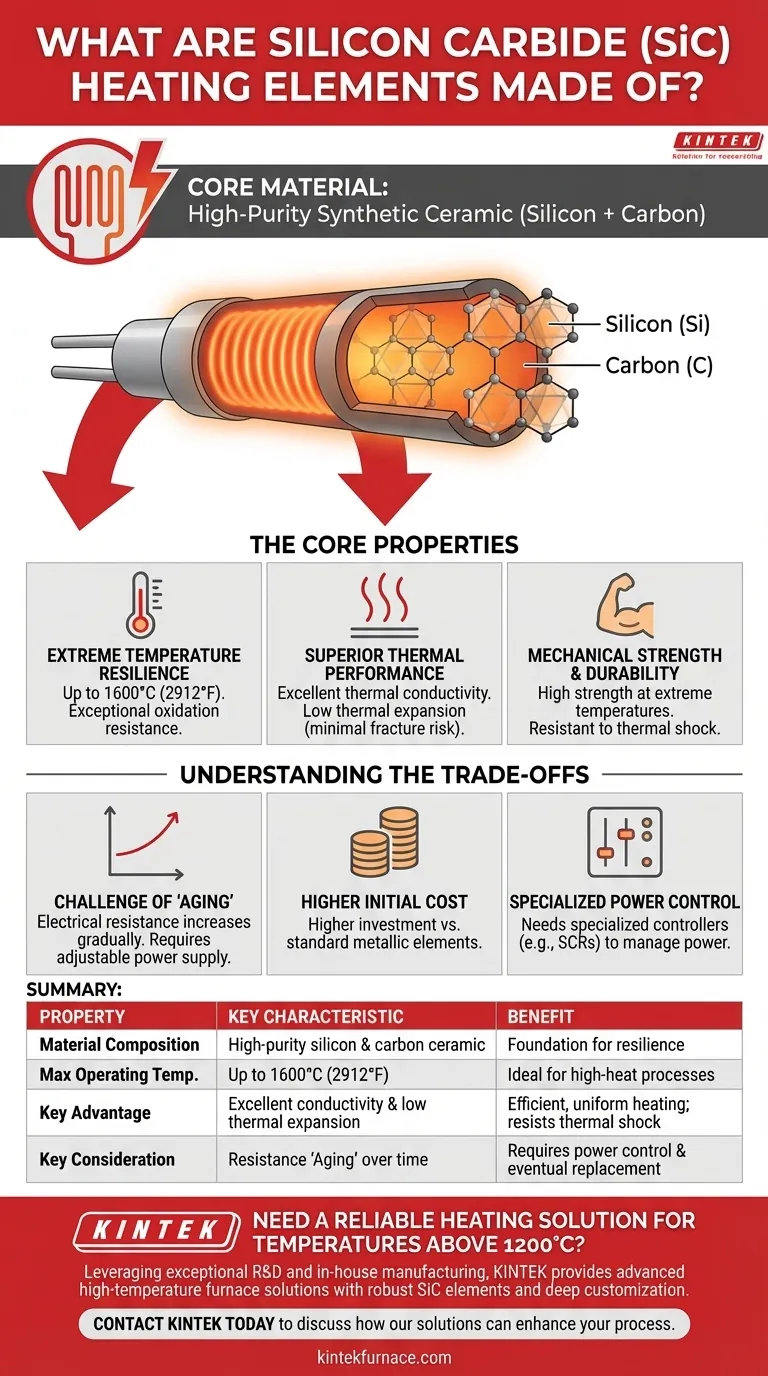

At their core, silicon carbide (SiC) heating elements are manufactured from a high-purity synthetic ceramic material composed of silicon and carbon. This material, known as silicon carbide, is specifically chosen for its unique ability to function reliably and efficiently in extremely high-temperature industrial and laboratory environments.

While the simple answer is "silicon carbide," the true reason for its use is the material's unique blend of extreme temperature resilience, thermal efficiency, and mechanical strength, which sets it apart from conventional metallic heating elements.

The Core Properties of Silicon Carbide

To understand why SiC is the material of choice for demanding heating applications, you must first understand its fundamental properties. These characteristics work in concert to deliver performance where other materials would fail.

Extreme Temperature Resilience

Silicon carbide can operate at furnace temperatures up to 1600°C (2912°F).

Its chemical structure provides exceptional resistance to oxidation, meaning it does not easily degrade or fail when exposed to oxygen at these elevated temperatures.

Superior Thermal Performance

SiC has excellent thermal conductivity, allowing it to transfer heat very efficiently and evenly throughout a furnace or process chamber.

It also possesses a low coefficient of thermal expansion. This means it expands and contracts very little when heated and cooled, drastically reducing internal stress and the risk of fracture from thermal shock.

Mechanical Strength and Durability

Unlike many materials that weaken with heat, silicon carbide maintains high strength even at extreme temperatures.

This inherent durability makes it highly resistant to the stresses of rapid heating and cooling cycles, contributing to a longer operational life in harsh conditions.

Understanding the Trade-offs

No material is perfect. A clear-eyed assessment of SiC requires acknowledging its operational costs and maintenance requirements. These are not flaws, but rather engineering trade-offs for achieving its high performance.

The Challenge of "Aging"

The most significant characteristic of SiC elements is "aging," a phenomenon where the element's electrical resistance gradually increases over its operational life.

This requires a power supply system, typically using transformers with multiple voltage taps, that can be adjusted to deliver more voltage over time to maintain the required power output. Eventually, the elements must be replaced, often in matched groups to ensure uniform heating.

Higher Initial Cost

SiC heating elements and their required power control systems represent a higher initial capital investment compared to standard metallic elements like Kanthal (FeCrAl).

This cost is weighed against their longer life, higher temperature capability, and energy efficiency in appropriate applications.

Specialized Power Control

Due to the aging effect, you cannot simply connect SiC elements to a fixed voltage source. They require specialized controllers, often Silicon Controlled Rectifiers (SCRs), that can precisely manage the power output as the element's resistance changes.

Is SiC the Right Choice for Your Application?

Your decision should be based on a clear analysis of your process requirements versus the material's distinct profile.

- If your primary focus is achieving process temperatures above 1200°C with high thermal uniformity: SiC is an industry-standard choice for demanding applications in ceramics, metallurgy, and glass manufacturing.

- If your primary focus is minimizing initial equipment cost for lower-temperature work: Traditional metallic heating elements are often the more economical and straightforward solution.

- If your primary focus is operational predictability and maintenance: You must budget and plan for the aging characteristic of SiC, which necessitates periodic power adjustments and eventual group replacement.

Understanding both the strengths and the specific operational demands of silicon carbide empowers you to select the right tool for your thermal processing goals.

Summary Table:

| Property | Key Characteristic | Benefit |

|---|---|---|

| Material Composition | High-purity silicon and carbon ceramic | Provides the foundation for extreme temperature resilience |

| Max Operating Temperature | Up to 1600°C (2912°F) | Ideal for demanding high-heat processes |

| Key Advantage | Excellent thermal conductivity & low thermal expansion | Ensures efficient, uniform heating and resists thermal shock |

| Key Consideration | Resistance 'Aging' over time | Requires specialized power control and eventual group replacement |

Need a reliable heating solution for temperatures above 1200°C?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Atmosphere Furnaces, often features robust SiC heating elements for superior performance.

We complement this with strong deep customization capabilities to precisely meet your unique experimental requirements, ensuring optimal thermal uniformity and efficiency.

Contact KINTEL today to discuss how our high-temperature furnace solutions can enhance your process.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What types of materials are used in heating elements and why? Discover the Best Choices for Your Application

- What are the thermal properties of SiC heating elements? Unlock High-Temp Efficiency and Durability

- What are the unique properties of silicon carbide heating elements? Key Benefits for High-Temp Performance

- What is the purpose of wrapping heating tapes around AP-SCVD gas lines? Prevent Condensation for Perfect Film Quality

- What are the common configurations of molybdenum heating elements? Choose the Right Type for Your Furnace

- What are the models of MoSi2 heating elements and their working temperatures? Choose the Right Model for Your High-Temp Needs

- Which industries commonly use high-temperature heating elements? Essential for Metallurgy, Chemicals, and Electronics

- How do Type-S thermocouples contribute to monitoring temperature fields in niobium furnaces for precise heat treatment?