At its core, the suitability of Silicon Carbide (SiC) for high-temperature heating elements comes from a unique combination of thermal, chemical, and electrical properties. It can operate at extremely high temperatures, efficiently transfer that heat to its surroundings, and resist the chemical degradation and physical stress that would cause lesser materials to fail.

While many materials can generate heat, Silicon Carbide's true value is its ability to do so reliably and efficiently at extreme temperatures (up to 1600°C) within aggressive industrial environments. It excels where longevity and consistent performance under stress are paramount.

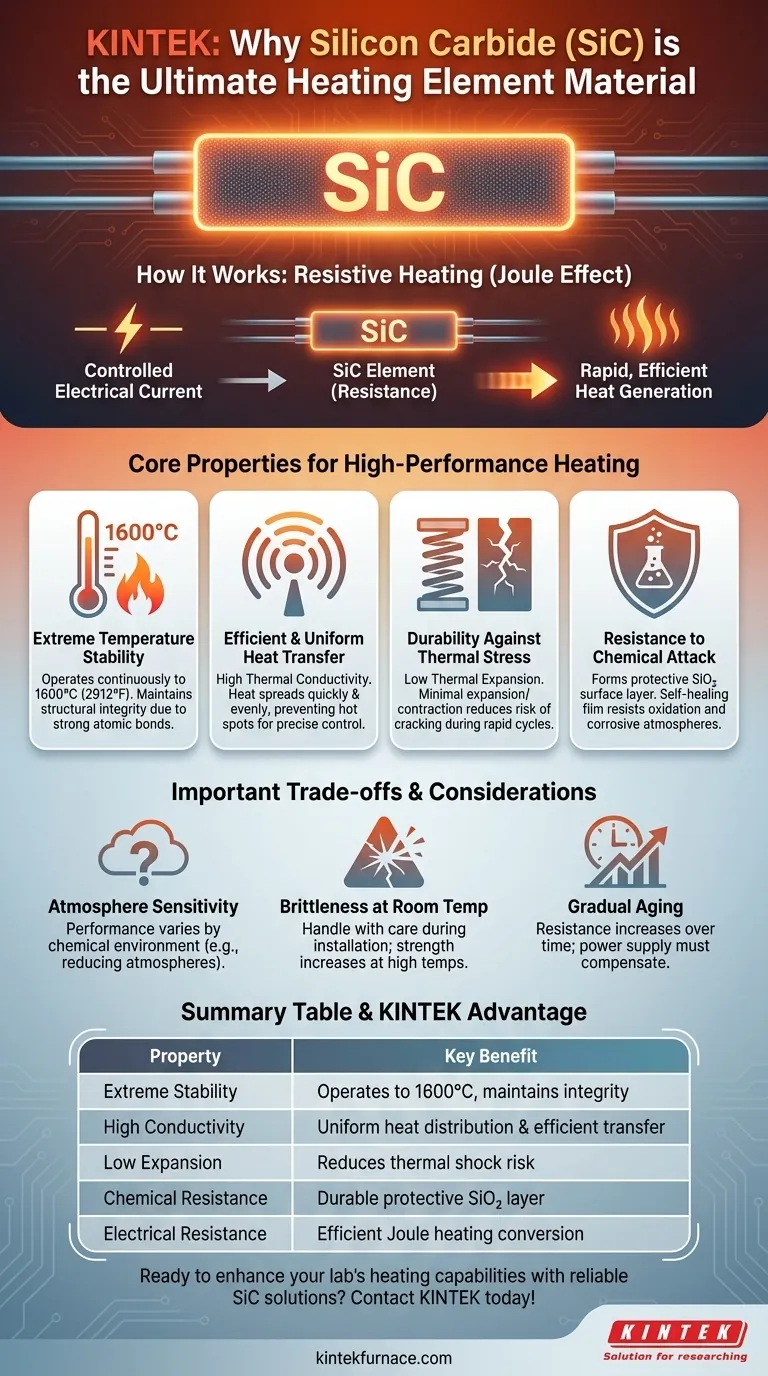

How SiC Functions as a Heating Element

The Principle of Resistive Heating

Silicon Carbide is a semiconductor. This means it is neither a perfect conductor nor a perfect insulator. When a controlled electrical current is passed through an SiC element, its inherent electrical resistance causes it to heat up rapidly, a phenomenon known as Joule heating.

This property allows SiC to convert electrical energy into thermal energy with high efficiency, forming the basis of its function as a heating element.

Core Properties for High-Performance Heating

Extreme Temperature Stability

SiC is a ceramic material that maintains its structural integrity and strength at very high temperatures. It can operate continuously at temperatures up to 1600°C (2912°F) in certain atmospheres.

This stability is a direct result of its strong atomic bonds and wide bandgap energy, which prevent the material from breaking down under intense thermal load.

Efficient and Uniform Heat Transfer

SiC possesses high thermal conductivity. This means heat generated within the element spreads quickly and evenly throughout its structure and radiates efficiently into the furnace or workspace.

This property prevents hot spots from forming on the element itself and ensures a uniform heating process, which is critical for applications requiring precise temperature control.

Durability Against Thermal Stress

A key advantage of SiC is its low coefficient of thermal expansion. As the element heats and cools, it expands and contracts very little.

This minimizes internal mechanical stress, dramatically reducing the risk of cracking or breaking during rapid temperature cycles. This resistance to thermal shock is a primary contributor to the element's long service life.

Resistance to Chemical Attack

Industrial furnaces often contain corrosive atmospheres. SiC naturally forms a protective surface layer of silicon dioxide (SiO₂) when heated in the presence of oxygen.

This self-healing protective film makes the element highly resistant to oxidation and many chemical compounds, ensuring it does not degrade quickly in harsh operating conditions.

Understanding the Trade-offs

Sensitivity to Atmosphere

While highly resistant to oxidation, the maximum operating temperature and lifespan of an SiC element can be affected by the specific chemical atmosphere. For example, they are particularly robust in reducing atmospheres.

It is crucial to match the element grade to the specific process environment to ensure optimal performance and longevity.

Brittleness at Room Temperature

Like most ceramics, SiC elements are hard but also brittle at room temperature. They must be handled with care during installation and maintenance to prevent mechanical shock or fracture.

Once at operating temperature, their strength increases significantly.

Gradual Aging

Over hundreds or thousands of hours of operation, SiC elements will experience a gradual increase in their electrical resistance. This "aging" is a natural process caused by slow changes in the material's crystalline structure.

Power supply systems for SiC elements must be able to compensate for this change by increasing the voltage over time to maintain constant power output.

Making the Right Choice for Your Application

By understanding these properties, you can determine if SiC is the correct choice for your specific goal.

- If your primary focus is rapid heating to extreme temperatures: SiC is an ideal choice due to its high-temperature stability and excellent thermal conductivity.

- If your primary focus is longevity in a harsh chemical environment: SiC's inherent resistance to oxidation and chemical attack provides unmatched durability.

- If your primary focus is reliability during frequent on/off cycles: SiC's low thermal expansion and resistance to thermal shock minimize the risk of failure.

By aligning the material's strengths with your application's demands, you can confidently leverage Silicon Carbide for processes that require intense, reliable heat.

Summary Table:

| Property | Key Benefit for Heating Elements |

|---|---|

| Extreme Temperature Stability | Operates up to 1600°C, maintaining structural integrity |

| High Thermal Conductivity | Ensures uniform heat distribution and efficient transfer |

| Low Thermal Expansion | Reduces risk of cracking from thermal shock |

| Chemical Resistance | Forms protective SiO₂ layer for durability in harsh environments |

| Electrical Resistance | Enables efficient Joule heating for energy conversion |

Ready to enhance your lab's heating capabilities with reliable SiC solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our SiC heating elements can deliver superior performance and longevity for your applications!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism