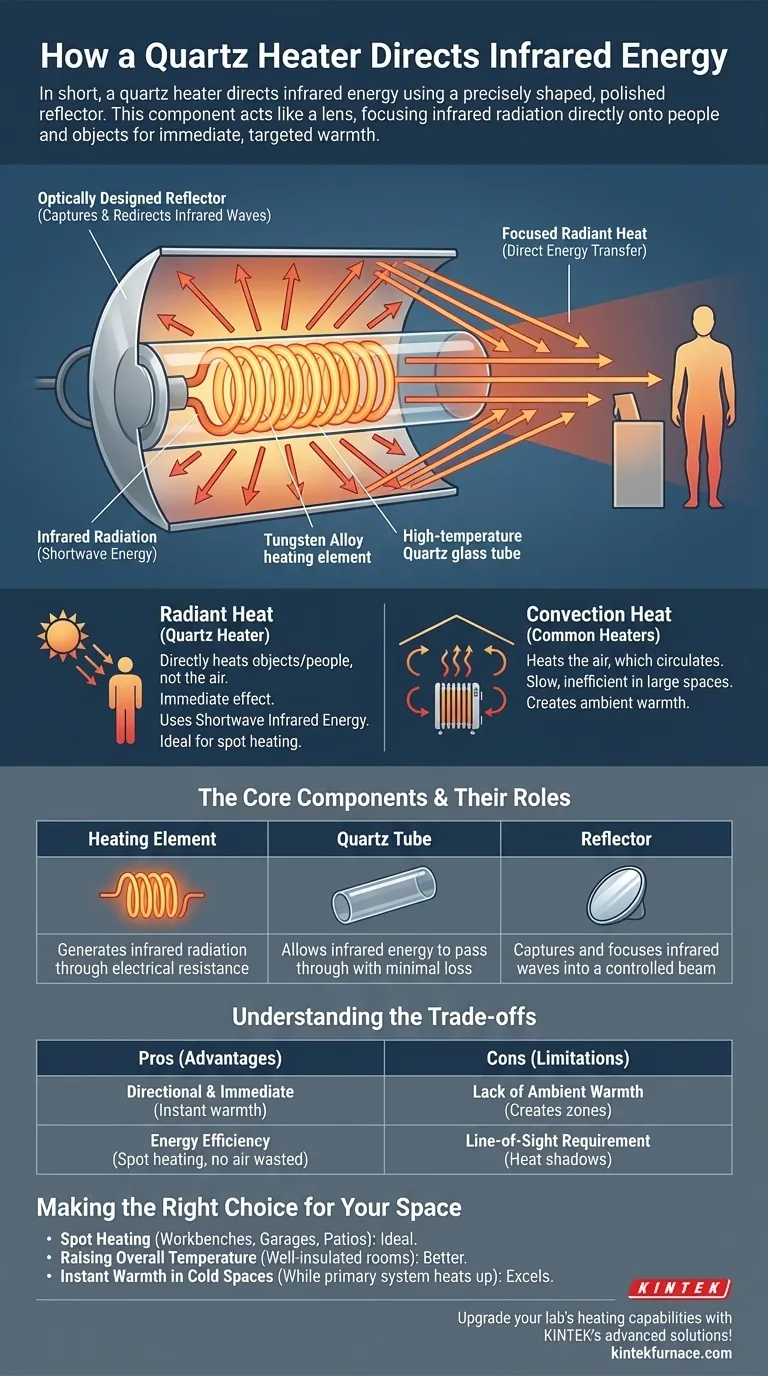

In short, a quartz heater directs infrared energy using a precisely shaped, polished reflector. This component sits behind the quartz heating element, capturing radiant energy that would otherwise be lost and focusing it forward into a specific, controlled pattern, much like the reflector in a car's headlight directs light onto the road.

A quartz heater isn't designed to heat the air in a room; it's a system for direct energy transfer. The reflector is a critical component that acts like a lens, focusing infrared radiation directly onto people and objects for immediate, targeted warmth.

The Core Components of a Quartz Heater

To understand how the energy is directed, it's essential to see how the three primary components work together as a system. Each part has a distinct and vital role.

The Heating Element

At the heart of the heater is a resistive element, often made of a tungsten alloy. When electricity passes through this element, it glows and generates intense heat in the form of infrared radiation.

The Quartz Tube

This heating element is encapsulated inside a tube made of quartz glass. Quartz is used for two key reasons: it is extremely durable and can withstand very high temperatures, and it is transparent to infrared radiation, allowing the energy to pass through it with minimal loss.

The Optically Designed Reflector

This is the component that answers your question directly. The reflector is a specially shaped piece of polished metal (like aluminum or steel) that sits behind the quartz tube. Its geometric design is not arbitrary; it is "optically designed" to capture and redirect the infrared waves, ensuring they are projected outward in a useful beam rather than dispersing in all directions.

How Infrared Energy Delivers Heat

The method of directing the energy is only half the story. The nature of the energy itself is what makes a quartz heater unique and dictates its ideal use cases.

Radiant Heat vs. Convection Heat

Most common space heaters use convection, meaning they heat the air, which then circulates to warm the room. This is slow and inefficient in large or drafty spaces.

A quartz heater uses radiant heat. It emits infrared waves that travel through the air until they strike an object—like you, a piece of furniture, or the floor. The energy is then absorbed by that object, causing it to become warmer. This is the same principle that allows you to feel the sun's warmth on a cool day.

The Importance of Wavelength

The heating elements in a quartz heater are designed to produce shortwave infrared energy. This high-intensity energy is particularly effective because it travels farther and is less susceptible to being diffused by air movement or wind, making it ideal for open or uninsulated areas.

Understanding the Trade-offs

A quartz heater's unique mechanism provides distinct advantages but also comes with clear limitations. Understanding these is crucial for selecting the right tool for the job.

Pro: Directional and Immediate

Because it heats objects directly, the warming effect is felt almost instantly. You don't have to wait for the entire volume of air in a room to heat up.

Pro: Energy Efficiency

By not wasting energy heating the air, especially in large or outdoor spaces, a quartz heater is highly efficient for "spot heating." Nearly all the energy consumed is converted directly into radiant heat you can feel.

Con: Lack of Ambient Warmth

A quartz heater will not raise the overall ambient temperature of a room significantly. It creates "zones" of warmth. If you move out of its direct line of sight, you will feel cold again almost immediately.

Con: Line-of-Sight Requirement

The heat is delivered in a straight line from the heater. Any object that blocks the path will create a "heat shadow," preventing the energy from reaching anything behind it.

Making the Right Choice for Your Space

Based on this, you can decide if a quartz heater's directional heating is right for your goal.

- If your primary focus is spot heating a specific area (like a workbench, garage, or patio table): A quartz heater is an ideal and highly efficient choice due to its direct, focused radiant energy.

- If your primary focus is raising the overall temperature of a well-insulated room: A convection heater is a better choice, as it will create a more consistent and comfortable ambient warmth throughout the space.

- If your primary focus is providing instant warmth in a cold space while a primary system heats up: A quartz heater excels at this, delivering immediate comfort without waiting.

Ultimately, understanding that a quartz heater warms you like the sun—directly and instantly—is the key to using it effectively.

Summary Table:

| Component | Role in Directing Infrared Energy |

|---|---|

| Heating Element | Generates infrared radiation through electrical resistance |

| Quartz Tube | Allows infrared energy to pass through with minimal loss |

| Reflector | Captures and focuses infrared waves into a controlled beam |

Upgrade your lab's heating capabilities with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to discuss how our tailored heating technologies can enhance your efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control