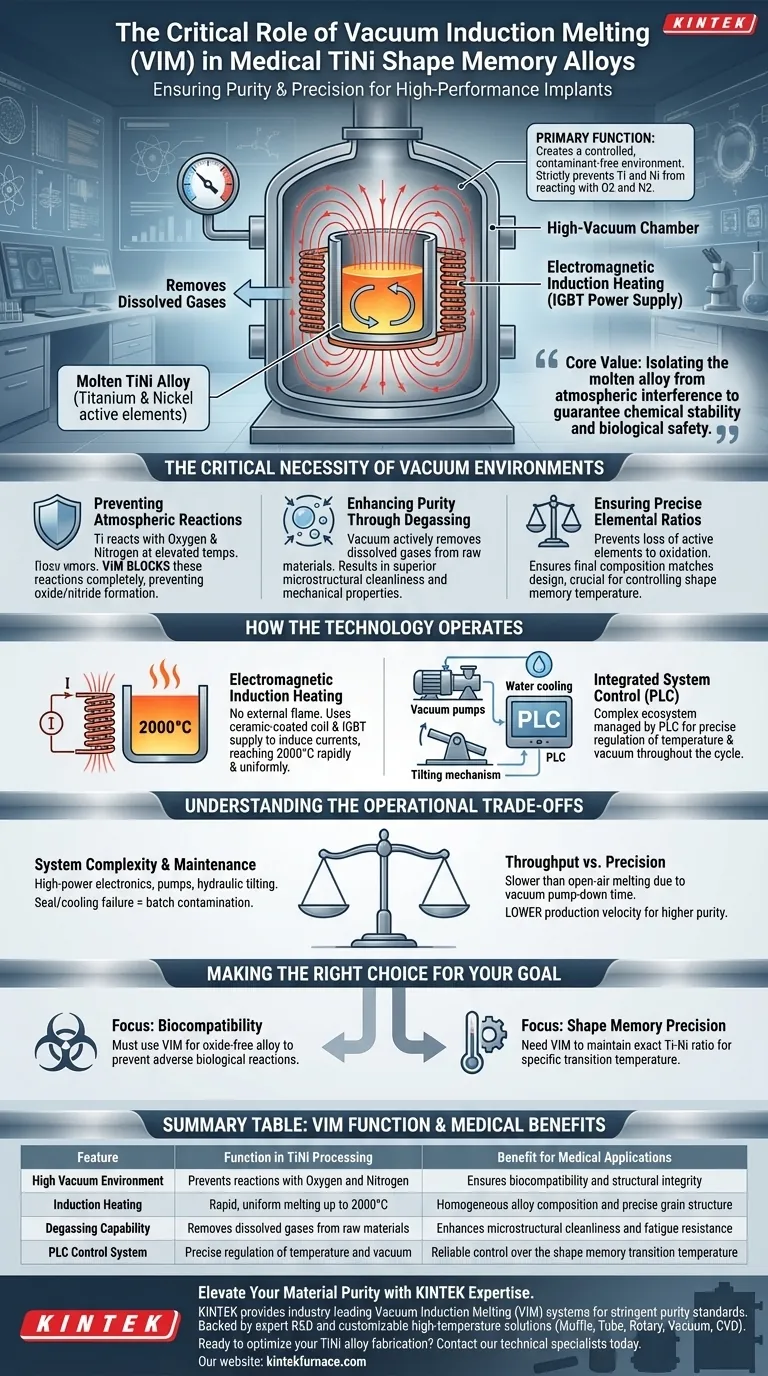

The primary function of a Vacuum Induction Melting (VIM) furnace is to create a controlled, contaminant-free environment for melting reactive metals. Specifically for medical TiNi (Titanium-Nickel) alloys, it utilizes electromagnetic induction within a high-vacuum chamber to generate heat. This process strictly prevents the active elements—titanium and nickel—from reacting with oxygen and nitrogen, ensuring the final ingot achieves the precise elemental ratio and high purity required for medical applications.

The core value of VIM technology lies in its ability to isolate the molten alloy from atmospheric interference. By eliminating oxidation and removing dissolved gases, it guarantees the chemical stability and biological safety essential for high-quality shape memory implants.

The Critical Necessity of Vacuum Environments

Preventing Atmospheric Reactions

Titanium is a highly active element that reacts aggressively with oxygen and nitrogen at elevated temperatures.

If melted in open air, these reactions form oxides and nitrides that compromise the alloy's structural integrity. The VIM furnace creates a high-vacuum environment that effectively blocks these reactions completely.

Enhancing Purity Through Degassing

Beyond simply preventing new contamination, the vacuum environment actively refines the material.

The pressure difference aids in the removal of dissolved gases already present in the raw materials. This results in a final ingot with superior microstructural cleanliness and mechanical properties.

Ensuring Precise Elemental Ratios

Medical shape memory alloys require an exact stoichiometric balance between Titanium and Nickel to function correctly.

Because VIM prevents the loss of active elements to oxidation, it ensures the final chemical composition matches the intended design precisely. This precision is vital for controlling the temperature at which the shape memory effect occurs.

How the Technology Operates

Electromagnetic Induction Heating

The furnace does not use an external heat source like a flame; instead, it uses an IGBT medium frequency power supply.

Current flows through a ceramic-coated copper coil, generating an electromagnetic field that induces electrical currents within the metal itself. This allows the material to reach temperatures up to 2000°C rapidly and uniformly.

Integrated System Control

A VIM furnace is a complex ecosystem comprising vacuum pumps, tilting mechanisms, and water-cooled interlayers.

An electrical control system, often managed via PLC (Programmable Logic Controller), orchestrates these components. This allows for the precise regulation of temperature and vacuum levels throughout the entire melting and casting cycle.

Understanding the Operational Trade-offs

System Complexity and Maintenance

While VIM offers superior quality, it introduces significant operational complexity compared to standard melting methods.

The system relies on the seamless integration of vacuum pumps, high-power electronics, and hydraulic tilting mechanisms. A failure in the vacuum seal or cooling system can lead to immediate batch contamination or equipment damage.

Throughput vs. Precision

The process is inherently slower than open-air induction melting due to the time required to pump down the chamber to a high vacuum.

Manufacturers must accept lower production velocity as the necessary cost for achieving the purity levels required by medical standards.

Making the Right Choice for Your Goal

For medical device manufacturers and metallurgists, the choice of melting technology dictates the success of the final product.

- If your primary focus is Biocompatibility: You must use VIM to ensure the alloy is free of oxide inclusions that could trigger adverse biological reactions.

- If your primary focus is Shape Memory Precision: You need VIM to maintain the exact Titanium-to-Nickel ratio, which defines the specific temperature at which the alloy changes shape.

VIM is not merely a melting method; it is a purification strategy essential for high-stakes medical material production.

Summary Table:

| Feature | Function in TiNi Processing | Benefit for Medical Applications |

|---|---|---|

| High Vacuum Environment | Prevents reactions with Oxygen and Nitrogen | Ensures biocompatibility and structural integrity |

| Induction Heating | Rapid, uniform melting up to 2000°C | Homogeneous alloy composition and precise grain structure |

| Degassing Capability | Removes dissolved gases from raw materials | Enhances microstructural cleanliness and fatigue resistance |

| PLC Control System | Precise regulation of temperature and vacuum | Reliable control over the shape memory transition temperature |

Elevate Your Material Purity with KINTEK Expertise

Precision is non-negotiable in the production of medical-grade alloys. KINTEK provides industry-leading Vacuum Induction Melting (VIM) systems designed to meet the most stringent purity and composition standards.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of lab high-temperature solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to your specific research or production needs.

Ready to optimize your TiNi alloy fabrication? Contact our technical specialists today to discover how KINTEK’s advanced furnace technology can enhance your laboratory's efficiency and product safety.

Visual Guide

References

- Jiajing Sun. Development of TiNi Alloy Superelastic Guidewire Needle for New Type of Medical Arthroscopic Surgery. DOI: 10.54097/mcmv2h54

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- Why is a graphite crucible used for melting Ti50Ni47Fe3? Optimize Heat & Efficiency in Vacuum Induction

- What are the main industrial applications of induction heating? Unlock Precision and Efficiency in Your Processes

- What are the main components of a Vacuum Induction Melting Furnace? Discover Key Parts for High-Purity Metal Production

- How does a Vacuum-arc melting furnace ensure the compositional uniformity of Ti–Mo–Fe alloy ingots? Master Homogeneity

- What is inductive stirring and how does it work? Master Molten Metal Mixing for Superior Alloys

- Why are higher frequencies needed in coreless induction furnaces for melting small loads of gold? Achieve Efficient Melting for Jewelry and Lab Samples

- What role does a vacuum induction furnace play in M2 steel refining? Achieve Deep Deoxidation and Purity