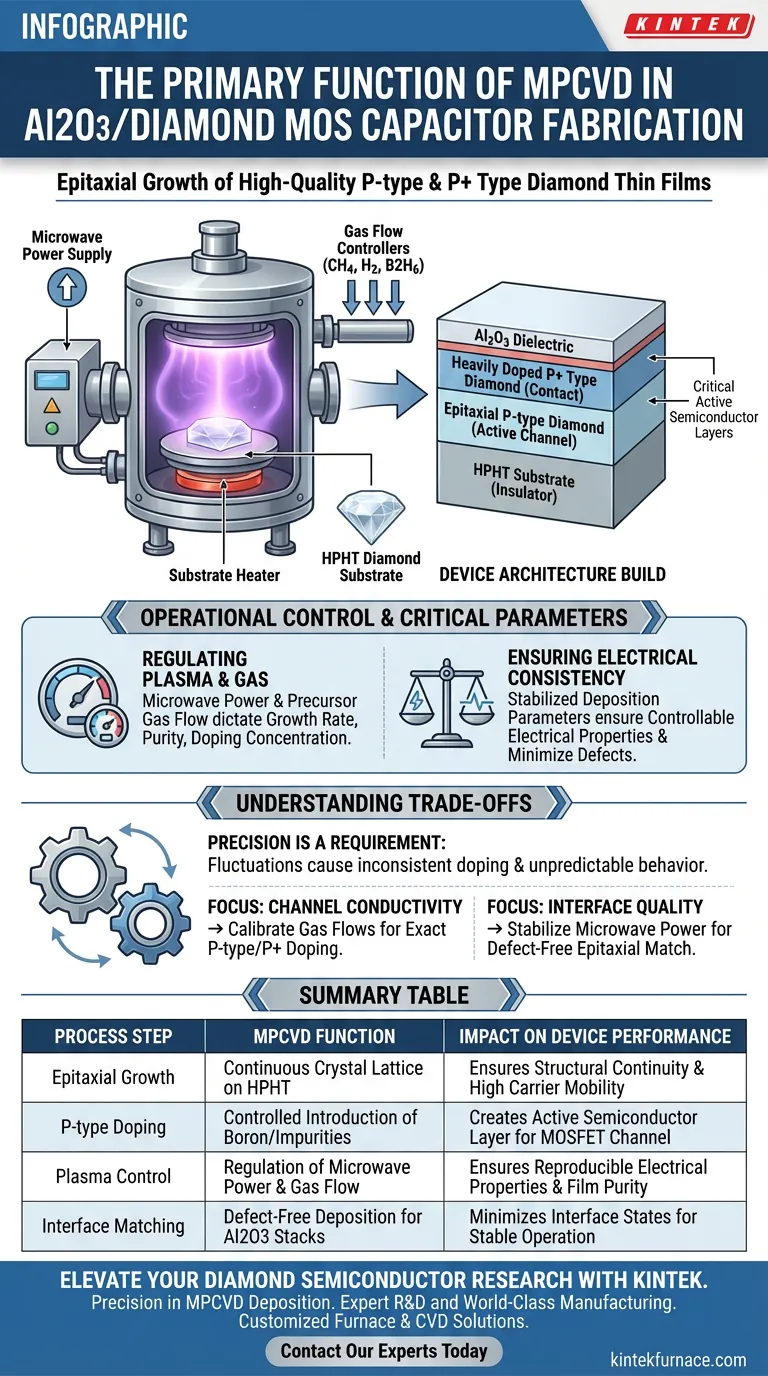

The primary function of a Microwave Plasma Chemical Vapor Deposition (MPCVD) system in this context is to epitaxially grow high-quality p-type and heavily doped p+ type diamond thin films onto High-Pressure High-Temperature (HPHT) single-crystal diamond substrates. This process is essential for creating the active semiconductor layers required for the device's operation.

MPCVD serves as the foundational fabrication step for diamond-based electronics, transforming a raw substrate into a functional semiconductor. By precisely controlling the growth environment, it defines the specific doping profiles necessary for the MOSFET channel to conduct electricity effectively.

The Role of MPCVD in Device Architecture

Epitaxial Growth on HPHT Substrates

The MPCVD system functions as a high-precision deposition tool. Its specific task is to grow new layers of diamond directly onto an existing HPHT single-crystal diamond substrate.

Because this process is epitaxial, the new layers continue the crystal lattice of the substrate perfectly. This ensures structural continuity, which is vital for high-performance electronic devices.

Creating Specific Doping Profiles

A raw diamond substrate is typically an electrical insulator. To function as a semiconductor, it must be doped.

The MPCVD system introduces specific impurities during the growth phase to create p-type and heavily doped p+ type layers. This ability to tune conductivity at the atomic level is what makes the fabrication of complex devices like capacitors and transistors possible.

Forming the Core MOSFET Channel

The layers grown by the MPCVD system are not merely structural coatings; they form the active region of the device.

The reference explicitly notes that these high-quality epitaxial layers serve as the core semiconductor material for MOSFET channels. Without this specific MPCVD step, there is no channel for electrons (or holes) to flow through, rendering the device non-functional.

Operational Control and Critical Parameters

Regulating Microwave Power and Gas Flow

The quality of the diamond film depends entirely on the stability of the plasma environment.

The MPCVD system allows for granular control over microwave power and precursor gas flow rates. Regulating these variables dictates the growth rate, purity, and doping concentration of the final film.

Ensuring Electrical Consistency

The ultimate goal of the MPCVD process is reproducibility. By stabilizing the deposition parameters, the system ensures the grown layers have controllable electrical properties.

This consistency is required to minimize defects that would otherwise degrade the performance of the Al2O3/diamond MOS capacitor stack.

Understanding the Trade-offs

The Necessity of Precision

While MPCVD allows for high-quality growth, it is highly sensitive to parameter fluctuations. The "precise control" mentioned in the reference is not a luxury; it is a requirement.

If microwave power or gas flow deviates, the doping concentration will become inconsistent. This results in a MOSFET channel with unpredictable electrical behavior, compromising the entire device.

Making the Right Choice for Your Goal

When utilizing MPCVD for diamond MOS capacitor fabrication, your operational focus should shift based on your specific requirements:

- If your primary focus is channel conductivity: Prioritize the precise calibration of precursor gas flows to achieve the exact p-type and p+ doping concentrations required.

- If your primary focus is interface quality: Focus on the stability of microwave power to ensure a defect-free epitaxial match with the HPHT substrate.

Success in this fabrication step relies on using the MPCVD system not just to grow diamond, but to engineer specific electrical properties through strict process control.

Summary Table:

| Process Step | MPCVD Function | Impact on Device Performance |

|---|---|---|

| Epitaxial Growth | Continuous crystal lattice formation on HPHT substrates | Ensures structural continuity and high carrier mobility |

| P-type Doping | Controlled introduction of boron/impurities | Creates the active semiconductor layer for the MOSFET channel |

| Plasma Control | Regulation of microwave power & gas flow | Ensures reproducible electrical properties and film purity |

| Interface Matching | Defect-free deposition for Al2O3 stacks | Minimizes interface states for stable capacitor operation |

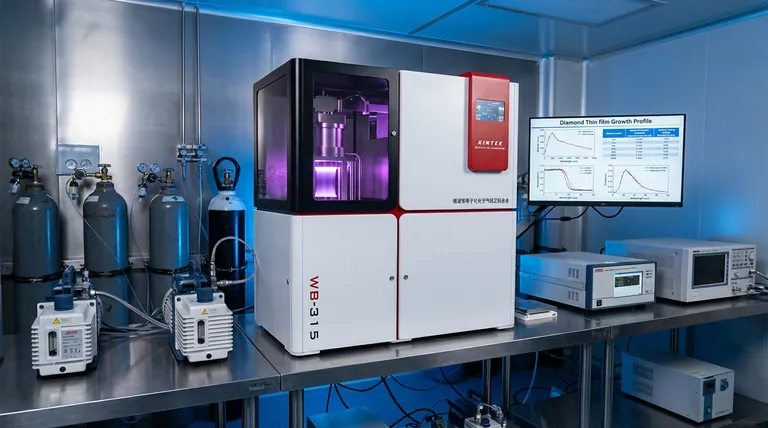

Elevate Your Diamond Semiconductor Research with KINTEK

Precision in MPCVD deposition is the difference between a failing device and a high-performance Al2O3/diamond MOS capacitor. Backed by expert R&D and world-class manufacturing, KINTEK provides industry-leading Microwave Plasma CVD systems, alongside our Muffle, Tube, and Vacuum furnace solutions. Whether you are engineering p-type doping profiles or complex epitaxial layers, our systems are fully customizable to meet your unique lab requirements.

Ready to achieve superior film quality? Contact our technical experts today to discuss your custom furnace or CVD needs.

Visual Guide

References

- Xufang Zhang, Norio Tokuda. Impact of water vapor annealing treatments on Al2O3/diamond interface. DOI: 10.1063/5.0188372

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What role does gas flow rate play in MPCVD? Mastering Deposition Rate and Film Uniformity

- How does MPCVD contribute to the production of advanced carbon films? Achieve Atomic-Level Control for Superior Performance

- What industrial applications benefit from MPCVD-produced films? Powering Next-Gen Electronics and Tools

- How does MPCVD achieve stable temperature control during diamond growth? Master Precise Thermal Management

- Why is MPCVD considered environmentally friendly? A Guide to Sustainable Thin-Film Manufacturing

- Why is the MPCVD method preferred over HFCVD for diamond synthesis? Achieve Purity and Control for High-Performance Diamonds

- What is the significance of stable discharge plasma in MPCVD? The Key to High-Quality Diamond Synthesis

- What techniques are used to determine the quality of MPCVD-deposited films? A Guide to Comprehensive Characterization