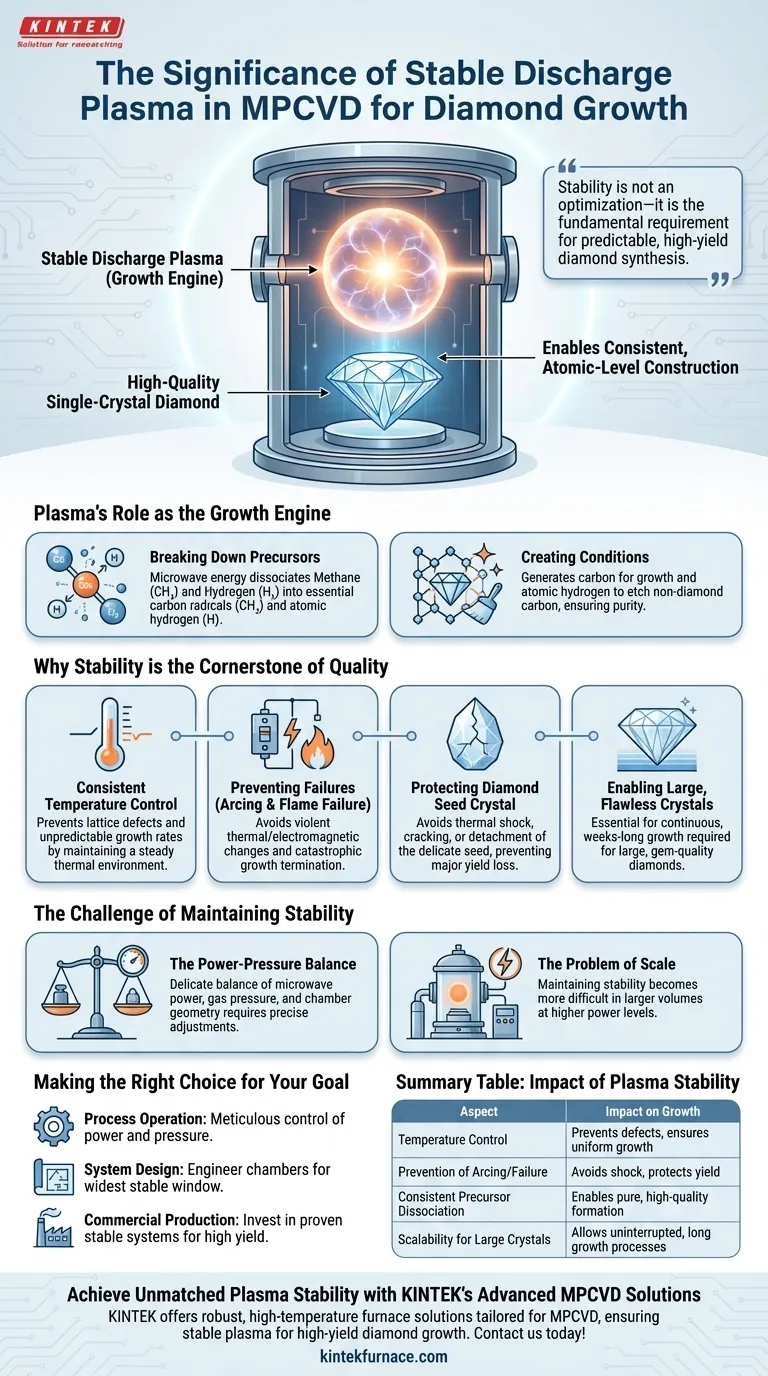

At its core, the stability of the discharge plasma is the single most critical factor for successfully growing large, high-quality single-crystal diamonds using the Microwave Plasma Chemical Vapor Deposition (MPCVD) method. This stability ensures the consistent, predictable environment required for the weeks-long, uninterrupted process of atomic-level construction, directly translating to viable industrial production.

Unstable plasma leads to catastrophic growth failures and defects. Therefore, achieving and maintaining plasma stability is not an optimization—it is the fundamental requirement for predictable, high-yield diamond synthesis.

The Plasma's Role as the Growth Engine

Breaking Down the Precursors

The MPCVD process begins with precursor gases, typically a mixture of methane (the carbon source) and a large excess of hydrogen. The microwave-generated plasma acts as a high-energy engine, breaking these gas molecules apart.

This dissociation creates the essential building blocks for diamond growth: carbon radicals (like CH₃) and, crucially, atomic hydrogen (H).

Creating the Conditions for Diamond

The plasma's function is twofold. It generates the carbon species that will add to the diamond lattice, and it generates the atomic hydrogen that selectively etches away any non-diamond carbon (like graphite) that might form. This continuous "purification" step is what allows a pure diamond crystal to grow.

Why Stability is the Cornerstone of Quality

Ensuring Consistent Temperature Control

The plasma is the primary heat source for the diamond seed substrate. A stable plasma provides a steady, unwavering thermal environment.

Fluctuations in the plasma's power or shape cause immediate temperature swings on the substrate. Inconsistent temperatures lead to defects in the crystal lattice and unpredictable growth rates.

Preventing Growth-Terminating Failures

Instability in the plasma can manifest as arcing (an electrical discharge) or flame failure (the plasma extinguishing or becoming misshapen).

These events cause an abrupt, violent change in the chamber's thermal and electromagnetic conditions. Even a momentary instability can be catastrophic.

Protecting the Diamond Seed Crystal

The most immediate consequence of arcing or plasma fluctuation is thermal shock to the substrate holder. This can cause the delicate diamond seed crystal to crack or detach from the holder entirely.

If the seed is lost, the entire growth run—which may have already taken hundreds of hours—is terminated. This is the most significant source of yield loss in the process.

Enabling Large, Flawless Crystals

Growing a large, gem-quality diamond requires a perfectly stable process running continuously for days or even weeks.

Any instability, no matter how brief, can introduce a structural defect or impurity into the crystal. A stable plasma is the only way to ensure the consistent, layer-by-layer atomic deposition needed for a flawless final product.

The Challenge of Maintaining Stability

The Power-Pressure Balance

Achieving a stable plasma involves a delicate balance between three key parameters: microwave power, gas pressure, and chamber geometry.

Changing one variable requires precise adjustments to the others to keep the plasma centered, well-defined, and free from fluctuation. This narrow processing window is a primary engineering challenge.

The Problem of Scale

As the demand for larger diamonds grows, reactors must become larger and operate at higher power levels.

Maintaining plasma stability in a larger volume at higher power is significantly more difficult. It requires sophisticated chamber design and microwave engineering to ensure the energy is delivered uniformly and without creating instabilities.

Making the Right Choice for Your Goal

Achieving stable plasma is the central objective that unifies operators, engineers, and stakeholders in diamond synthesis.

- If your primary focus is process operation: Your goal is the meticulous control of microwave power and chamber pressure, responding to any drift to prevent deviation from the stable state.

- If your primary focus is system design: Your goal is to engineer a reaction chamber and microwave delivery system that creates the widest and most robust window for stable plasma operation.

- If your primary focus is commercial production: Your goal is to invest in systems and processes that prove their plasma stability, as this is the most reliable predictor of high yield and consistent quality.

Ultimately, mastering plasma stability is what transforms the theoretical possibility of diamond growth into a reliable and scalable industrial reality.

Summary Table:

| Aspect of Plasma Stability | Impact on Diamond Growth |

|---|---|

| Temperature Control | Prevents lattice defects and ensures uniform growth rates |

| Prevention of Arcing/Failure | Avoids thermal shock and seed crystal loss, protecting yield |

| Consistent Precursor Dissociation | Enables pure, high-quality diamond formation by maintaining steady atomic hydrogen and carbon radical levels |

| Scalability for Large Crystals | Allows for uninterrupted, weeks-long growth processes necessary for large, flawless diamonds |

Achieve Unmatched Plasma Stability with KINTEK's Advanced MPCVD Solutions

Struggling with plasma instability in your diamond synthesis process? KINTEK leverages exceptional R&D and in-house manufacturing to provide laboratories with robust, high-temperature furnace solutions tailored for MPCVD applications. Our product line, including Vacuum & Atmosphere Furnaces and specialized CVD/PECVD Systems, is engineered with deep customization capabilities to meet your unique experimental requirements—ensuring the stable plasma environment essential for high-yield, high-quality diamond growth.

Contact us today to discuss how we can optimize your MPCVD process for superior results. Reach out via our contact form to get started!

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What are the key features of CVD tube furnaces for 2D material processing? Unlock Precision Synthesis for Superior Materials

- What are the advantages of CVD tube furnace sintering systems? Achieve Superior Material Control and Purity

- What are the key design features of a CVD Tube Furnace? Optimize Your Material Synthesis with Precision

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What is the process for synthesizing transition metal dichalcogenides (TMDs) using CVD tube furnaces? Master High-Quality Thin Film Growth