At its core, MPCVD achieves superior temperature control by enabling the smooth and continuous adjustment of microwave power. This precise regulation of energy directly governs the plasma's intensity within the reaction chamber, ensuring the consistent thermal environment required for high-quality diamond synthesis.

Stable temperature in MPCVD is not merely about maintaining a setpoint; it is the fundamental enabler of the process. It prevents catastrophic physical failures while ensuring the delicate chemical reactions proceed correctly, making high-speed, high-quality diamond growth possible.

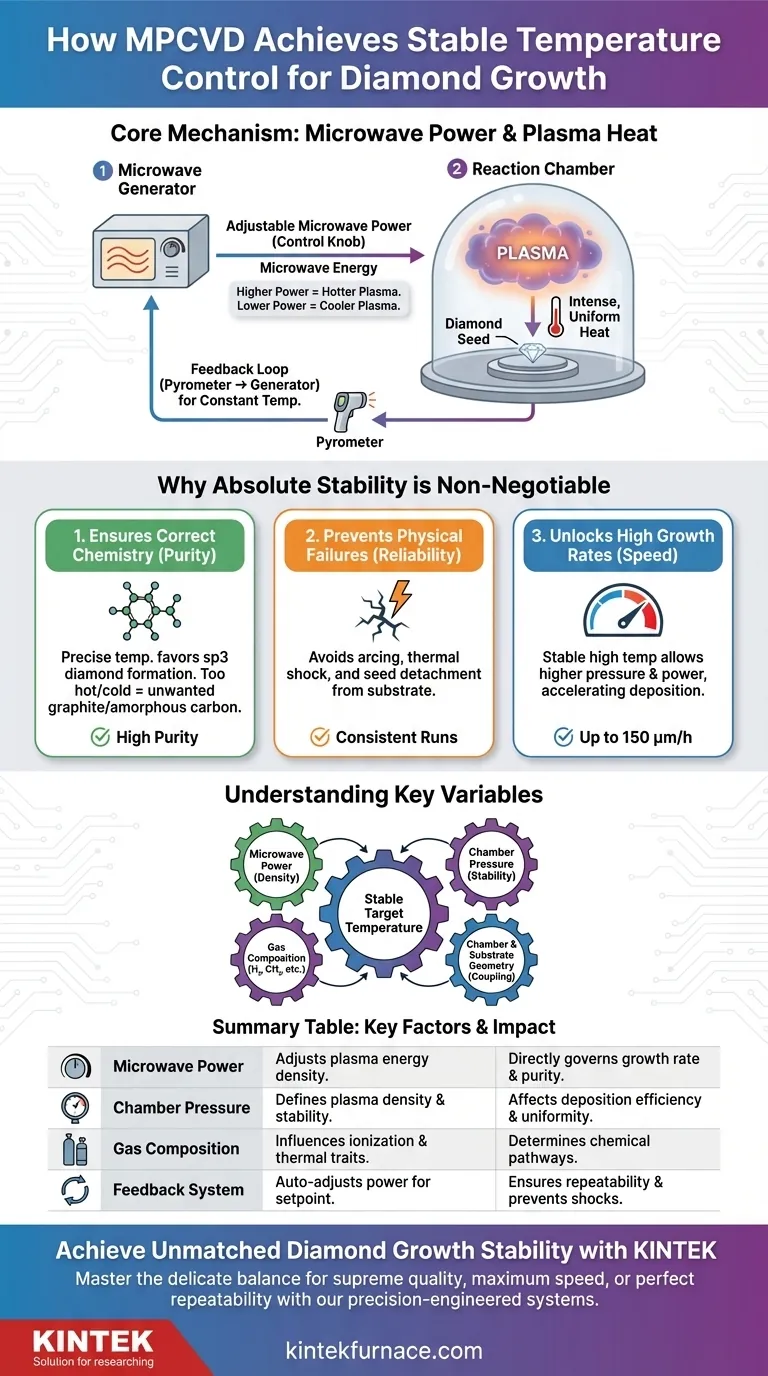

The Core Mechanism: From Microwaves to Plasma Heat

To understand temperature control, you must first understand how heat is generated. In MPCVD, the heat does not come from a traditional heating element but from the plasma itself.

How Microwaves Energize the Plasma

The process begins when a mixture of gases (typically hydrogen, methane, and sometimes nitrogen or oxygen) is introduced into a low-pressure chamber.

Microwave energy is then directed into the chamber. This energy excites electrons in the gas, causing them to oscillate violently and collide with other atoms and molecules.

This chain reaction of collisions strips electrons from atoms, creating a high-density, ionized gas known as a plasma. The immense energy from these constant collisions is what generates the intense, uniform heat.

Microwave Power as the Control Knob

The temperature of the plasma is a direct function of its energy density. By precisely increasing or decreasing the input microwave power, the system can directly regulate the intensity of the atomic collisions.

This relationship is the key to control. More power equals a hotter, denser plasma; less power equals a cooler, less dense one. Modern MPCVD systems use sophisticated feedback loops, where a pyrometer measures the substrate temperature and automatically adjusts the microwave generator's output to maintain the target temperature with exceptional stability.

Why Absolute Stability is Non-Negotiable

Minor fluctuations in temperature can have major consequences during diamond growth. The stability provided by microwave power adjustment is crucial for three primary reasons.

1. Ensuring the Correct Diamond Chemistry

The deposition of diamond is a highly temperature-dependent chemical process. The reaction gases must break apart into specific atomic groups (like H, CH3) that participate in growth.

If the temperature is too low, the reaction rate slows dramatically. If it is too high, it can favor the formation of unwanted materials like graphite or other forms of amorphous carbon, ruining the diamond's purity and structure. A stable temperature ensures the chemical reactions proceed at the optimal rate for sp3-bonded carbon (diamond) formation.

2. Preventing Physical Growth Failures

Temperature instability is a primary cause of failed growth runs. As noted in the source material, inconsistent power can lead to arcing or plasma flame failure.

These events cause rapid thermal shocks to the substrate. The resulting stress can cause the microscopic diamond seed crystals to physically detach from the substrate surface, immediately terminating the growth process and wasting the entire batch.

3. Unlocking High Growth Rates

A stable and precisely controlled temperature environment allows operators to push the process to its limits. By maintaining an optimal thermal window, one can increase both the chamber pressure and the microwave power.

This increases the concentration and activity of the reactive species in the plasma, dramatically accelerating the deposition rate. This control is how MPCVD achieves growth rates of up to 150 μm/h, orders of magnitude higher than less stable methods.

Understanding the Key Variables

While microwave power is the primary control lever, it does not operate in a vacuum. Achieving a stable target temperature requires balancing several interdependent factors.

Power vs. Pressure

Increasing microwave power often necessitates a corresponding adjustment in chamber pressure. These two parameters work together to define the plasma's density, shape, and temperature. An imbalance can lead to an unstable or inefficient plasma.

Gas Composition

The specific mix of gases (H2, CH4, N2, etc.) directly impacts the plasma's characteristics. Different gases ionize at different energy levels, meaning the gas recipe must be factored into the power settings needed to achieve a target temperature.

Substrate and Chamber Geometry

The physical setup, including the substrate holder material and the dimensions of the resonant cavity, influences how the microwave energy couples with the gas. A well-designed system ensures efficient energy transfer and a uniform plasma ball, which is critical for consistent heating across the substrate.

Making the Right Choice for Your Goal

Your approach to temperature control should align with your primary objective for diamond growth.

- If your primary focus is maximum quality and purity: You must maintain a very narrow, stable temperature window to prevent the formation of non-diamond carbon and minimize crystal defects.

- If your primary focus is the fastest possible growth rate: You will operate at the higher end of the stable temperature range, which demands a robust system capable of delivering high, continuous microwave power without fluctuation.

- If your primary focus is run-to-run repeatability: You must rely on a well-calibrated, automated feedback control system (pyrometer to power generator) to eliminate human error and ensure consistent outcomes.

Ultimately, mastering temperature control in MPCVD is about mastering the precise delivery of microwave energy to the plasma.

Summary Table:

| Key Factor | Role in Temperature Control | Impact on Diamond Growth |

|---|---|---|

| Microwave Power | Primary control knob; adjusts plasma energy density. | Directly governs growth rate and chemical purity. |

| Chamber Pressure | Works with power to define plasma density and stability. | Affects deposition efficiency and uniformity. |

| Gas Composition | Influences plasma ionization and thermal characteristics. | Determines the chemical pathways for diamond formation. |

| Feedback System | Uses pyrometer to auto-adjust power for setpoint stability. | Ensures repeatability and prevents thermal shocks. |

Achieve Unmatched Diamond Growth Stability with KINTEK

Mastering the delicate balance of temperature, pressure, and power is the key to successful MPCVD diamond synthesis. Whether your goal is supreme crystal quality, maximum growth speed, or perfect batch-to-batch repeatability, you need a furnace system engineered for precision and stability.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and specialized CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements for advanced materials development.

Ready to enhance your lab's capabilities? Contact our experts today to discuss how our solutions can bring stability and precision to your most critical processes.

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What are the advantages of CVD tube furnace sintering systems? Achieve Superior Material Control and Purity

- What is the process for synthesizing transition metal dichalcogenides (TMDs) using CVD tube furnaces? Master High-Quality Thin Film Growth