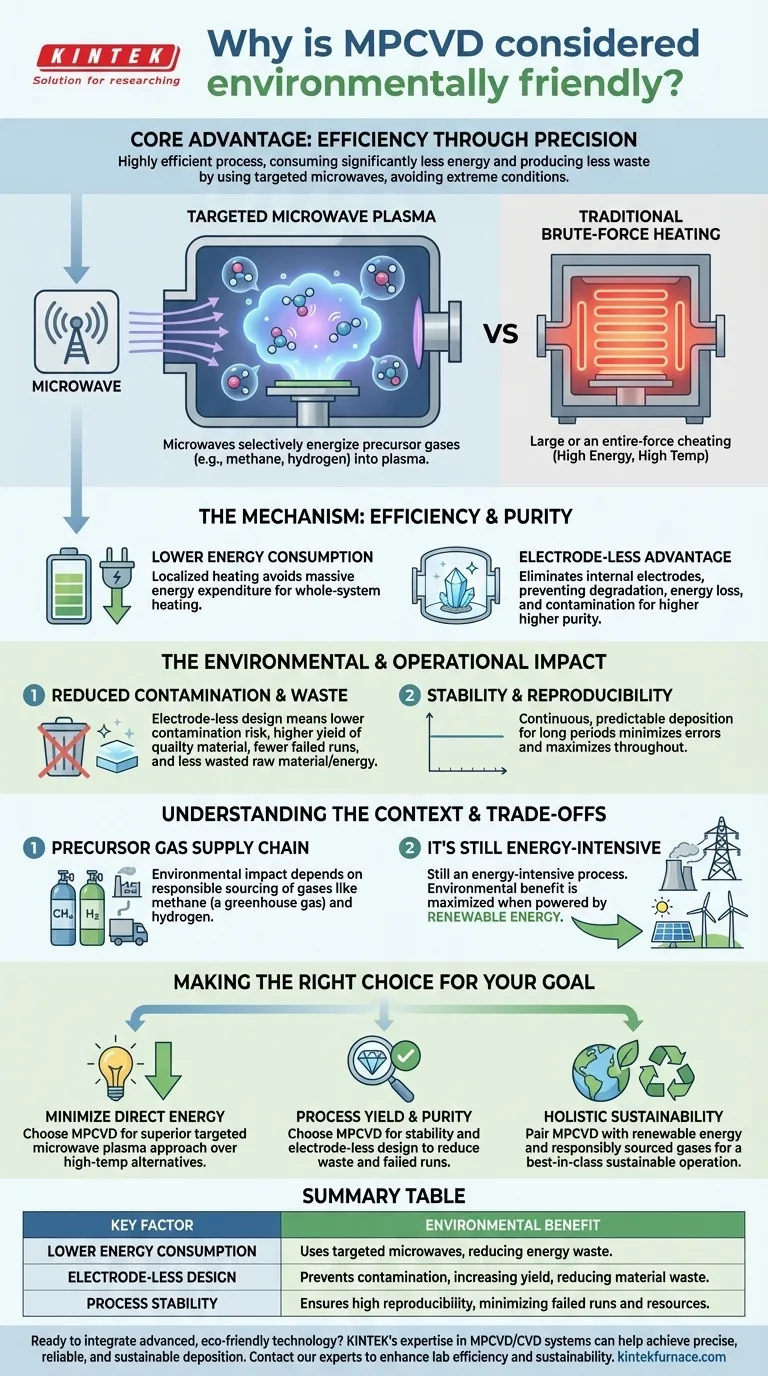

At its core, Microwave Plasma Chemical Vapor Deposition (MPCVD) is considered environmentally friendly because it is a highly efficient process. It consumes significantly less energy and produces less waste compared to traditional methods by using microwaves to generate a plasma, avoiding the need for extreme temperatures and pressures.

The key advantage of MPCVD is not just that it uses less energy, but how it uses it. By precisely targeting gases with microwaves instead of using brute-force heating, the process minimizes energy waste, reduces contamination, and increases production reliability.

The Mechanism: Efficiency Through Precision

MPCVD's environmental benefits stem directly from its sophisticated and controlled deposition mechanism. It represents a significant technological advancement over older, less efficient methods.

Lower Energy Consumption

Unlike high-pressure, high-temperature (HPHT) methods that heat an entire system, MPCVD uses microwaves to selectively energize precursor gases (like methane and hydrogen) into a plasma.

This localized heating is far more energy-efficient. It avoids the massive energy expenditure required to maintain the extreme conditions found in other deposition techniques.

The Electrode-less Advantage

A key feature of modern MPCVD systems is their electrode-less design. The microwaves are coupled directly into the chamber, eliminating the need for internal electrodes which can degrade over time.

This design enhances energy efficiency as there is no energy loss through degrading components. More importantly, it prevents electrode material from sputtering and contaminating the growing film, ensuring higher purity.

The Environmental and Operational Impact

The efficiency of the MPCVD process translates into tangible environmental and operational benefits, making it a preferred choice for sustainable, high-tech manufacturing.

Reduced Contamination and Waste

The electrode-less nature of MPCVD directly reduces the risk of process contamination. This leads to a higher yield of high-quality, usable material.

Fewer failed or contaminated production runs mean less wasted raw material, less wasted energy, and a more sustainable operation overall.

Stability and Reproducibility

MPCVD technology is known for its stability, allowing for continuous deposition over long periods without a drop in quality.

This reliability is a crucial environmental benefit. A predictable and reproducible process minimizes errors, maximizes throughput, and ensures that the energy and materials invested result in a viable product.

Understanding the Context and Trade-offs

While MPCVD is highly efficient, no industrial process is without an environmental footprint. A complete understanding requires acknowledging the context.

Precursor Gas Supply Chain

The primary inputs for MPCVD diamond growth are gases like methane (a potent greenhouse gas) and hydrogen. The production and transportation of these gases carry their own environmental impact.

While the MPCVD process itself is efficient, its overall "green" profile depends on sourcing these gases from the most sustainable supply chains possible.

It's Still Energy-Intensive

Compared to brute-force methods like HPHT, MPCVD is a clear winner in energy efficiency. However, in absolute terms, it is still an energy-intensive industrial process that requires a stable and significant power supply.

Its environmental advantage is therefore maximized when the facility is powered by renewable energy sources, which mitigates the impact of its electricity consumption.

Making the Right Choice for Your Goal

Your evaluation of MPCVD should align with your specific objectives, whether they are purely environmental, operational, or a mix of both.

- If your primary focus is minimizing direct energy consumption: MPCVD is the superior choice over high-temperature alternatives due to its targeted microwave plasma approach.

- If your primary focus is process yield and material purity: The stability and electrode-less design of MPCVD reduce waste from contamination and failed runs, making it a more efficient and reliable option.

- If your primary focus is holistic sustainability: Pair the MPCVD process with a renewable energy source and responsibly sourced precursor gases to create a truly best-in-class sustainable manufacturing operation.

Ultimately, choosing MPCVD is a decision for a smarter, more precise manufacturing process that achieves superior results with a lower environmental cost.

Summary Table:

| Key Factor | Environmental Benefit |

|---|---|

| Lower Energy Consumption | Uses targeted microwaves instead of brute-force heating, reducing energy waste. |

| Electrode-less Design | Prevents component contamination, increasing yield and reducing material waste. |

| Process Stability | Ensures high reproducibility, minimizing failed runs and wasted resources. |

Ready to integrate advanced, eco-friendly technology into your lab?

KINTEK's expertise in high-temperature furnace solutions, including advanced CVD/PECVD systems, can help you achieve precise, reliable, and sustainable thin-film deposition. Our strong R&D and deep customization capabilities ensure your MPCVD system is tailored to your unique research or production goals.

Contact our experts today to discuss how our solutions can enhance your lab's efficiency and sustainability.

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does MPCVD compare to other CVD methods like HFCVD and plasma torch? Uncover Superior Film Purity and Uniformity

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance

- What are the key advantages of MPCVD in diamond synthesis? Achieve High-Purity, Scalable Diamond Production

- Why is MPCVD considered a cornerstone of modern materials science and engineering? Unlock High-Purity Materials for Innovation

- In which industries is the microwave plasma chemical vapor deposition system commonly used? Unlock High-Purity Material Synthesis