At its core, the primary advantage of Microwave Plasma Chemical Vapor Deposition (MPCVD) is its ability to create high-purity diamonds with exceptional control and consistency. Unlike other methods, MPCVD uses microwave energy to generate a clean, stable plasma, avoiding the contamination and process instability that can plague older techniques. This results in superior quality, scalability, and economic viability for industrial applications.

The crucial takeaway is that MPCVD elevates diamond synthesis from a sensitive laboratory process to a scalable and reproducible manufacturing technology. Its key advantages—purity, control, and scalability—are not just incremental improvements; they are fundamental shifts that enable the production of high-quality diamonds for demanding industrial and electronic applications.

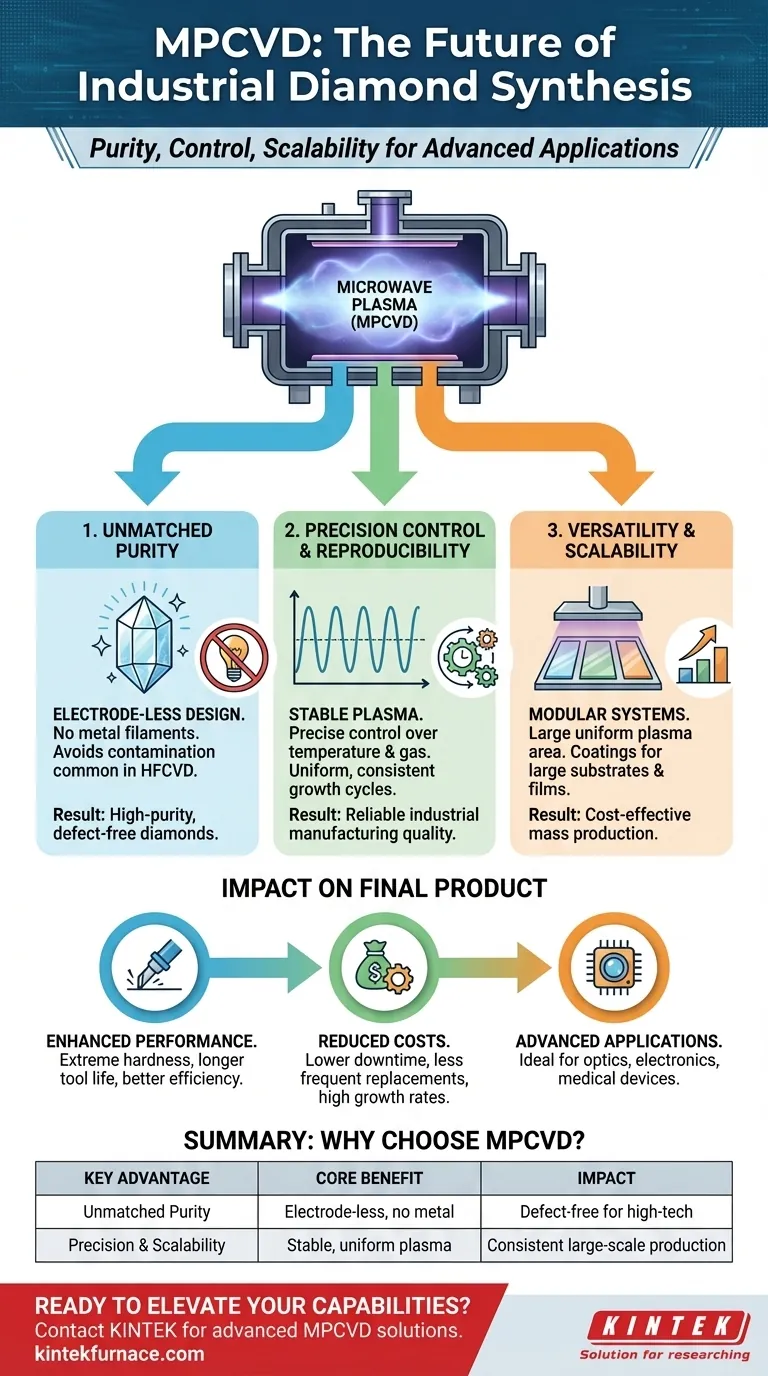

The Pillars of MPCVD's Superiority

MPCVD stands out by solving the core challenges of diamond growth: contamination, process instability, and scalability. Its unique mechanism is the source of its primary advantages.

Pillar 1: Unmatched Purity via a Contamination-Free Process

The most significant advantage of MPCVD is its electrode-less design. The process uses microwave energy to excite gases into a plasma state within a sealed chamber.

This method completely avoids the use of hot metal filaments (like tungsten or tantalum) or electrodes, which are common in other CVD techniques like HFCVD. Those metal components degrade at high temperatures and can introduce impurities, compromising the diamond's quality and performance.

Pillar 2: Precision Control and Reproducibility

MPCVD offers precise and stable control over the critical growth parameters, including temperature and gas composition. The microwave-generated plasma is remarkably stable and uniform over a large area.

This stability allows for continuous, long-duration growth cycles without a drop in quality. The result is highly reproducible sample quality, which is essential for any industrial manufacturing process where consistency is paramount.

Pillar 3: Versatility and Scalability

The MPCVD process is compatible with a wide array of gases, allowing operators to fine-tune the growth recipe for specific applications and even produce diamonds with tailored properties.

Furthermore, MPCVD systems are modular and scalable. The ability to generate a large, uniform plasma area enables the coating of larger substrates, making it the most promising method for large-scale industrial production of both diamond films and large, single-crystal diamonds.

How These Advantages Impact the Final Product

The technical benefits of the MPCVD process directly translate into a superior final product with tangible economic value.

Enhanced Performance and Lifespan

Diamonds produced via MPCVD exhibit extreme hardness and can be honed to precise, sharp cutting edges. For industrial tooling, this means a significant increase in tool life and improved cutting efficiency.

Reduced Manufacturing Costs

The reproducibility of MPCVD and the longer lifespan of the diamond tools it creates reduce the need for frequent tool replacements and costly machine downtime. This, combined with high growth rates (up to 150 μm/h), makes the process highly cost-effective at scale.

Suitability for Advanced Applications

The high purity and low defect density of MPCVD diamonds make them ideal for high-tech fields beyond cutting tools. Their properties are perfectly suited for demanding applications in optics, advanced electronics, and even medical devices.

Understanding the Trade-offs: MPCVD vs. Other Methods

To fully appreciate MPCVD, it is useful to compare it directly with older, alternative methods.

The Problem with Hot Filaments (HFCVD)

Hot Filament CVD (HFCVD) is a common alternative, but it suffers from two major drawbacks. First, the hot filament is a direct source of metal contamination, which is detrimental to the diamond's quality.

Second, the filaments themselves are sensitive to certain process gases, which limits the chemistry you can use and can increase costs due to the need for frequent filament replacement. MPCVD has neither of these limitations.

The Challenge of Other Plasma Methods

Methods like DC Plasma Jet (DC-PJ) CVD can achieve high growth rates but often struggle to produce a plasma that is as large, stable, and uniform as that in an MPCVD system.

This lack of uniformity and stability makes it more difficult to achieve the consistent, high-quality results over large areas that MPCVD delivers, positioning MPCVD as the superior choice for industrial production.

Making the Right Choice for Your Goal

Your choice of synthesis method depends entirely on your end goal. The advantages of MPCVD become clear when specific outcomes are prioritized.

- If your primary focus is producing the highest-purity, defect-free single crystal diamonds: MPCVD is the definitive choice due to its contamination-free, highly controlled, and stable growth environment.

- If your primary focus is large-scale industrial coating and production: MPCVD's scalability, uniformity over large areas, and high reproducibility make it the most reliable and cost-effective option.

- If your primary focus is rapid, small-scale research where budget is the main constraint: Older methods like HFCVD might be considered, but you must accept the inherent trade-offs in purity, material properties, and process control.

Ultimately, choosing MPCVD is a decision to prioritize quality, consistency, and the scalability required for modern technological demands.

Summary Table:

| Key Advantage | Core Benefit | Impact on Final Product |

|---|---|---|

| Unmatched Purity | Electrode-less design avoids metal contamination | High-purity, defect-free diamonds for electronics and optics |

| Precision Control & Reproducibility | Stable, uniform plasma enables consistent growth | Reliable industrial manufacturing with consistent quality |

| Versatility & Scalability | Large, uniform plasma area and modular design | Cost-effective large-scale production of diamond films and single crystals |

Ready to elevate your diamond synthesis capabilities? KINTEK's advanced MPCVD systems leverage our exceptional R&D and in-house manufacturing to deliver precisely controlled, contamination-free diamond growth. Whether you're developing cutting tools, electronic components, or optical devices, our deep customization capabilities ensure your system meets unique experimental requirements. Contact our experts today to discuss how our MPCVD solutions can enhance your research and production outcomes!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- How is CVD classified based on physical characteristics of vapor? Explore AACVD and DLICVD Methods

- Why is keeping maintenance records important for MPCVD equipment? Ensure Reliability and Quality in Crystal Growth

- Why is maintaining gas pipelines important in MPCVD equipment? Ensure Purity and Safety in Crystal Growth

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth