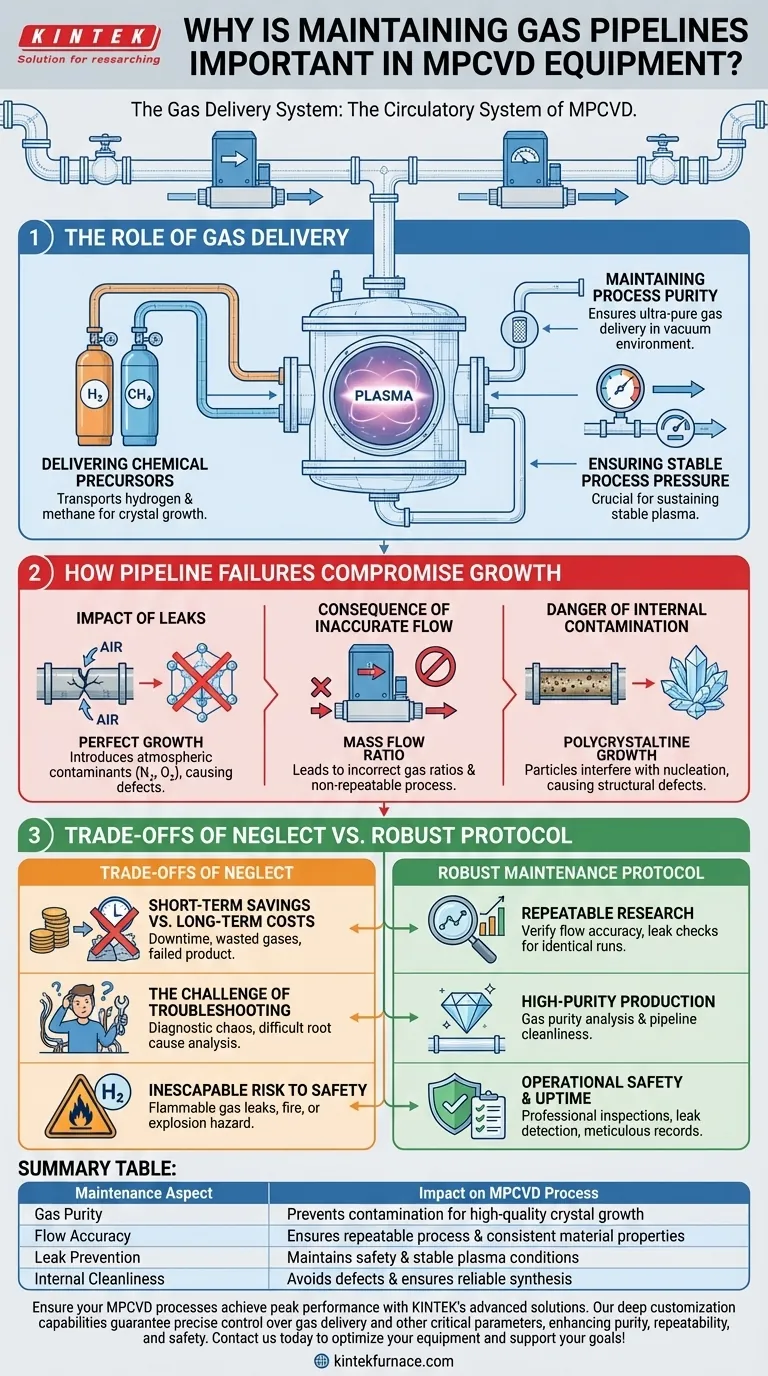

In short, maintaining the gas pipelines in Microwave Plasma Chemical Vapor Deposition (MPCVD) equipment is critical because they directly control the purity, composition, and pressure of the reactive gases used for crystal growth. Any failure in this system—such as a leak, blockage, or inaccurate flow meter—will immediately compromise the quality of the final material, ruin process repeatability, and can introduce significant safety hazards.

The gas delivery system is not merely plumbing; it is the circulatory system of the MPCVD process. Just as the health of an organism depends on pure, well-regulated blood flow, the success of high-quality crystal growth depends entirely on a pristine and precisely controlled gas supply.

The Role of Gas Delivery in MPCVD

To understand the importance of maintenance, we must first recognize that the gas pipelines are the sole delivery mechanism for the fundamental building blocks of the synthetic crystal. Their function is precise and multi-faceted.

Delivering the Chemical Precursors

The pipelines transport the specific gases, such as hydrogen (H₂) and methane (CH₄), that serve as the raw material for the deposition process. The composition of this gas mixture is a primary determinant of the final crystal's properties.

Maintaining Process Purity

The MPCVD process operates in a highly controlled vacuum environment to prevent contamination. The pipelines are an extension of this environment, responsible for delivering ultra-pure gases without introducing any external impurities from the atmosphere.

Ensuring Stable Process Pressure

The flow rate and leak-tightness of the gas lines are essential for maintaining the exact chamber pressure required to sustain a stable plasma. Fluctuations in pressure can extinguish the plasma or alter its characteristics, directly impacting growth conditions.

How Pipeline Failures Compromise Crystal Growth

A seemingly minor issue in a gas pipeline has a direct and often disastrous effect on the final product. The link between pipeline integrity and crystal quality is absolute.

The Impact of Leaks

Even a microscopic leak introduces atmospheric contaminants like nitrogen and oxygen into the gas stream. These impurities get incorporated into the crystal lattice, creating defects, discoloration, and significantly degrading the material's electronic or optical performance.

The Consequence of Inaccurate Flow

If a mass flow controller is inaccurate or a line is partially blocked, the gas ratio will be incorrect. This makes the process fundamentally non-repeatable. The result is inconsistent growth rates and unpredictable material properties from one run to the next, rendering research data unreliable and production batches unusable.

The Danger of Internal Contamination

Dust, oils, or other particulates inside uncleaned pipelines can be carried into the reaction chamber. These particles can interfere with crystal nucleation on the substrate, leading to polycrystalline growth, structural defects, and ultimately, failed synthesis.

Understanding the Trade-offs of Neglect

Deferring pipeline maintenance might seem like a way to save time, but it is a high-risk gamble that introduces severe technical and financial liabilities.

Short-Term Savings vs. Long-Term Costs

Skipping a few hours of maintenance can easily lead to weeks of downtime. Diagnosing a contamination issue, cleaning the entire chamber, and recalibrating the system after a failure costs far more in lost time, wasted high-purity gases, and failed product than proactive maintenance ever will.

The Challenge of Troubleshooting

When a growth run fails, a poorly maintained system creates diagnostic chaos. Without detailed maintenance records, it becomes nearly impossible to determine if the root cause was a gas leak, a contaminated source, an incorrect flow rate, or another system variable.

The Inescapable Risk to Safety

Many gases used in MPCVD, particularly hydrogen, are highly flammable. A leak is not just a quality control issue; it is a serious safety hazard that can lead to fire or explosion. Maintenance must be performed by trained professionals who understand these risks.

Implementing a Robust Maintenance Protocol

Your approach to maintenance should be dictated by your primary operational goal. A systematic protocol is the foundation of reliable and safe operation.

- If your primary focus is repeatable research: Your top priority is verifying the accuracy of mass flow controllers and conducting regular leak checks to ensure process parameters are identical between runs.

- If your primary focus is high-purity material production: You must emphasize gas purity analysis and the internal cleanliness of the pipelines to eliminate any source of contamination.

- If your primary focus is operational safety and uptime: Your protocol must include professional inspections, comprehensive leak detection procedures, and meticulous maintenance records to ensure long-term reliability and a safe working environment.

Ultimately, meticulous care of your gas delivery system is the bedrock upon which all successful MPCVD outcomes are built.

Summary Table:

| Maintenance Aspect | Impact on MPCVD Process |

|---|---|

| Gas Purity | Prevents contamination for high-quality crystal growth |

| Flow Accuracy | Ensures repeatable process and consistent material properties |

| Leak Prevention | Maintains safety and stable plasma conditions |

| Internal Cleanliness | Avoids defects and ensures reliable synthesis |

Ensure your MPCVD processes achieve peak performance with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like CVD/PECVD Systems, tailored to your unique needs. Our deep customization capabilities guarantee precise control over gas delivery and other critical parameters, enhancing purity, repeatability, and safety. Don't let pipeline issues compromise your results—contact us today to discuss how we can optimize your equipment and support your research or production goals!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth

- Why is keeping maintenance records important for MPCVD equipment? Ensure Reliability and Quality in Crystal Growth

- What are some challenges associated with MPCVD? Overcome High Costs and Complexity for Diamond Synthesis

- How is CVD classified based on physical characteristics of vapor? Explore AACVD and DLICVD Methods

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision