In Microwave Plasma Chemical Vapor Deposition (MPCVD), the primary role of inert gas doping is to act as a catalyst that significantly accelerates the growth rate of single-crystal diamonds. Gases like nitrogen or argon are introduced in small, controlled amounts to alter the plasma chemistry and speed up the reactions occurring on the diamond's growth surface.

The core insight is that doping doesn't work by creating more raw material from the source gas. Instead, it fundamentally changes the chemical pathways on the diamond surface, making the process of incorporating carbon atoms more efficient.

The Core Mechanism: Catalysis, Not Dissociation

The Common Misconception

A frequent assumption is that adding a gas like nitrogen helps break down more methane (CH4), the carbon source gas, thereby providing more carbon atoms for growth.

However, research indicates this is not the primary mechanism. The addition of nitrogen does not significantly increase the overall dissociation of methane in the plasma.

The Reality: A Surface-Level Catalyst

Nitrogen's true role is that of a catalyst, specifically for the chemical reactions happening on the diamond's surface.

It accelerates the rate at which carbon-containing species from the plasma are successfully incorporated into the diamond's crystal lattice.

The Chemical Shift: CN vs. C2 Groups

The introduction of nitrogen alters the balance of active chemical species within the plasma.

Specifically, it increases the strength and concentration of cyano (CN) groups while reducing the strength of diatomic carbon (C2) groups. This chemical shift is a key indicator of the catalytic process taking place.

The Result: Accelerated Growth

This nitrogen-induced change in the plasma's chemical environment directly leads to a faster growth rate. The modified surface chemistry allows carbon to be added to the crystal structure more rapidly than it would in a pure hydrogen/methane environment.

Understanding the Trade-offs

The Impact on Crystal Quality

While nitrogen doping is highly effective for increasing growth speed, it is a delicate balance. Faster growth always carries the risk of introducing defects into the crystal lattice.

Excessive nitrogen can lead to a higher concentration of impurities or structural flaws, potentially impacting the diamond's clarity, color, and electronic properties.

The Need for Precise Control

The effect of nitrogen is highly dependent on its concentration. Too little will have a negligible effect on the growth rate.

Conversely, too much can poison the growth surface, introduce unwanted defects, and ultimately degrade the quality of the final single-crystal diamond. Optimizing this concentration is a critical aspect of the MPCVD process.

Making the Right Choice for Your Goal

Achieving consistent results requires understanding how to leverage nitrogen doping for your specific objective.

- If your primary focus is maximizing growth rate: Carefully controlled nitrogen doping is the most effective known method to leverage its catalytic effect on surface reactions.

- If your primary focus is achieving the highest possible crystal purity: Use nitrogen doping cautiously or avoid it entirely, as even small amounts can be incorporated as defects and require extensive process optimization to mitigate.

- If your primary focus is process control and diagnostics: Monitor the plasma's optical emission spectrum for the relative intensity of CN and C2 groups to get a real-time indication of your doping strategy's effectiveness.

By understanding nitrogen not as more fuel but as a precise surface catalyst, you gain direct control over the diamond growth equation.

Summary Table:

| Aspect | Role of Inert Gas Doping (e.g., Nitrogen) |

|---|---|

| Primary Function | Acts as a surface catalyst, accelerating carbon incorporation into the diamond lattice. |

| Key Mechanism | Shifts plasma chemistry: increases CN groups, reduces C2 groups. |

| Impact on Growth Rate | Significantly increases speed of single-crystal diamond deposition. |

| Trade-off | Higher growth rates can introduce crystal defects if not precisely controlled. |

| Optimal Use Case | Ideal for applications prioritizing speed over ultra-high purity. |

Need precise control over your MPCVD diamond growth process? At KINTEK, we understand that optimizing parameters like inert gas doping is critical for achieving the desired balance between growth rate and crystal quality. Our advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, are engineered for exceptional process stability and control. Leveraging our strong in-house R&D and deep customization capabilities, we can tailor a system to meet your unique experimental requirements—whether you're focused on high-speed growth or ultra-pure crystal synthesis. Contact our experts today to discuss how we can enhance your lab's capabilities!

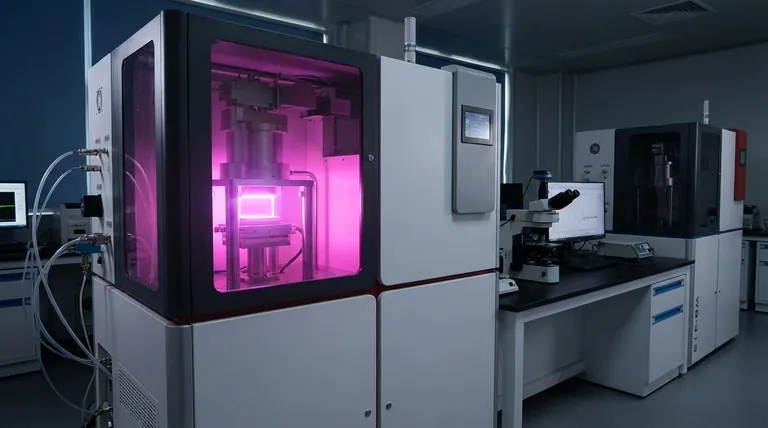

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What are some challenges associated with MPCVD? Overcome High Costs and Complexity for Diamond Synthesis

- What are some applications of MPCVD? Unlock High-Purity Diamond for Advanced Engineering

- How is CVD classified based on physical characteristics of vapor? Explore AACVD and DLICVD Methods

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- Why is keeping maintenance records important for MPCVD equipment? Ensure Reliability and Quality in Crystal Growth