In short, Microwave Plasma Chemical Vapor Deposition (MPCVD) is a process that grows high-purity polycrystalline diamond films by energizing a gas mixture into a plasma using microwaves. This method is uniquely suited for producing optical components because it creates exceptionally transparent and durable diamond layers without the contamination inherent in other techniques.

The core advantage of MPCVD is its ability to create a high-density, contaminant-free plasma. This allows for the rapid growth of optically pure diamond with precisely controlled properties, making it the superior method for demanding applications like high-power laser windows and durable lenses.

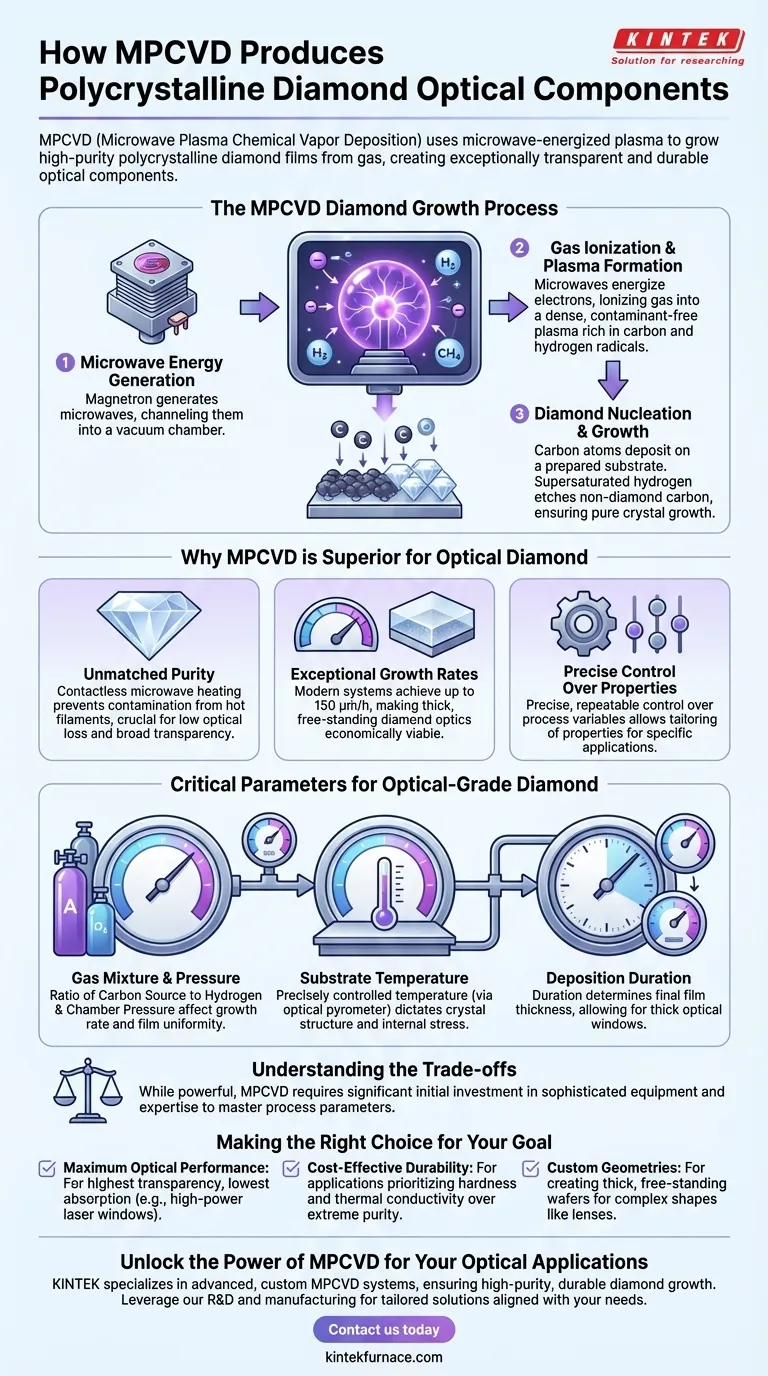

How the MPCVD Process Creates Diamond

The MPCVD process transforms simple gases into one of the world's hardest and most optically transparent materials. This is accomplished inside a highly controlled vacuum chamber environment.

The Role of Microwave Energy

An MPCVD reactor uses a magnetron to generate microwaves, which are channeled into a deposition chamber. This focused electromagnetic field does not create heat directly but energizes free electrons within the chamber.

Gas Ionization and Plasma Formation

These energized electrons oscillate violently and collide with atoms in the process gas—typically a mixture of hydrogen and a carbon source like methane. These collisions create a cascade effect, stripping more electrons and ionizing the gas into a plasma, a glowing ball of reactive atomic groups.

The MPCVD method achieves a high ionization level (over 10%), resulting in a dense, stable plasma that is rich in carbon and hydrogen radicals.

Diamond Nucleation and Growth

Inside this plasma, carbon-containing molecules break apart. The resulting carbon atoms deposit onto a prepared substrate placed within the chamber. The supersaturated hydrogen environment selectively etches away any non-diamond carbon (graphite), ensuring only a pure diamond crystal lattice can form and grow.

Why MPCVD is Superior for Optical Diamond

While other methods can produce diamond, MPCVD offers a unique combination of benefits that make it the industry standard for high-performance optical components.

Unmatched Purity and Quality

Unlike older methods like Hot Filament CVD (HFCVD), MPCVD has no hot internal components like filaments that can degrade and introduce impurities into the diamond film. This contactless heating via microwaves is critical for achieving the low optical loss and broad transparency needed for windows, lenses, and prisms.

Exceptional Growth Rates

Modern MPCVD systems can achieve remarkably high growth rates, reaching up to 150 μm per hour. This is orders of magnitude faster than conventional processes, making the production of thick, free-standing diamond optics economically viable.

Precise Control Over Properties

The final quality of the diamond is directly tied to the process conditions. MPCVD offers precise, stable, and repeatable control over all critical variables, allowing engineers to tailor the material's properties for specific applications.

Critical Parameters for Optical-Grade Diamond

Achieving a uniform, transparent diamond film requires mastering several key process variables.

The Gas Mixture and Pressure

The ratio of the carbon source (e.g., methane) to hydrogen determines the growth rate and crystal quality. The pressure within the vacuum chamber influences the plasma density and stability, which in turn affects the uniformity of the deposited film.

Substrate Temperature

The temperature of the substrate must be precisely controlled, typically with an optical pyrometer. This temperature dictates how carbon atoms bond to the surface, directly impacting the crystal structure and internal stress of the final diamond component.

Deposition Duration

The duration of the process determines the final thickness of the diamond film. Thanks to stable process conditions, MPCVD can run for extended periods to grow the thick layers required for robust optical windows.

Understanding the Trade-offs

While powerful, the MPCVD process is not without its complexities. The primary trade-off is the significant initial investment in sophisticated equipment.

An MPCVD reactor is a complex system requiring a microwave generator, waveguides, a high-vacuum chamber, precise gas flow controllers, and temperature monitoring systems. Mastering the interplay between these components and the process parameters requires significant expertise. The precision that makes the process so effective also means there is little room for error.

Making the Right Choice for Your Goal

The decision to use MPCVD-grown diamond depends on your specific performance requirements.

- If your primary focus is maximum optical performance: MPCVD is the only choice for applications requiring the highest transparency, lowest absorption, and durability, such as windows for high-power lasers or scientific instruments.

- If your primary focus is cost-effective durability: For applications where extreme optical purity is secondary to hardness and thermal conductivity, MPCVD provides a scalable path to producing robust diamond-coated components.

- If your primary focus is creating custom geometries: The control offered by MPCVD allows for the growth of thick, free-standing diamond wafers that can then be laser-cut and polished into complex shapes like lenses and prisms.

Ultimately, MPCVD empowers engineers to leverage the exceptional properties of diamond in applications that were previously impossible.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Uses microwave plasma to grow high-purity diamond films from gas mixtures (e.g., hydrogen and methane). |

| Key Advantages | Contaminant-free plasma, high growth rates (up to 150 μm/h), precise control over properties, and suitability for optical applications. |

| Applications | High-power laser windows, durable lenses, prisms, and other optical components requiring transparency and durability. |

| Critical Parameters | Gas mixture ratios, chamber pressure, substrate temperature, and deposition duration for uniform, high-quality diamond. |

Unlock the Power of MPCVD for Your Optical Applications

At KINTEK, we specialize in advanced high-temperature furnace solutions, including our custom MPCVD systems, designed to meet the unique demands of laboratories and industries. Leveraging our exceptional R&D and in-house manufacturing, we provide tailored solutions that ensure high-purity, durable diamond growth for optical components like laser windows and lenses. Our expertise in deep customization allows us to precisely align with your experimental needs, enhancing performance and efficiency.

Ready to elevate your optical component production? Contact us today to discuss how our MPCVD technology can benefit your projects!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- Why is maintaining gas pipelines important in MPCVD equipment? Ensure Purity and Safety in Crystal Growth

- What are some applications of MPCVD? Unlock High-Purity Diamond for Advanced Engineering

- Why is the temperature control system important in MPCVD equipment? Ensure Precise Diamond Growth and Process Stability

- Why is keeping maintenance records important for MPCVD equipment? Ensure Reliability and Quality in Crystal Growth

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth