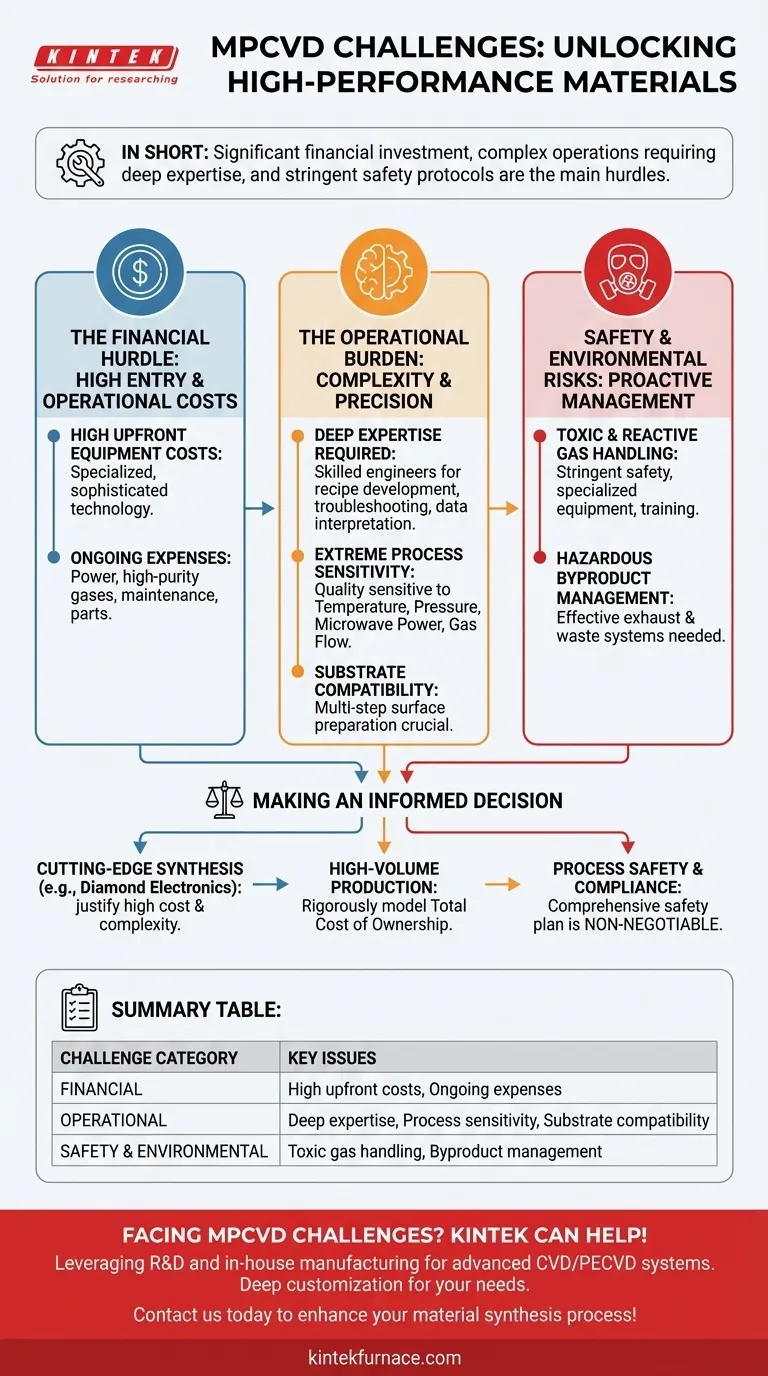

In short, the main challenges of Microwave Plasma-Enhanced Chemical Vapor Deposition (MPCVD) center on its significant financial investment, the operational complexity requiring deep expertise, and stringent safety protocols for handling hazardous materials. Success with MPCVD demands precise control over numerous process parameters, where even small deviations can compromise the final material quality.

While MPCVD is a uniquely powerful technique for fabricating high-performance materials like synthetic diamond, its implementation is not a simple matter. The core challenge is that its high cost, operational difficulty, and safety risks are intertwined, requiring a holistic and well-funded strategy to overcome.

The Financial Hurdle: High Costs of Entry and Operation

Choosing MPCVD is a significant financial commitment that extends far beyond the initial purchase. Understanding the total cost of ownership is critical.

High Upfront Equipment Costs

The initial purchase of an MPCVD system represents a substantial capital expenditure. These are specialized, high-technology instruments, and their price reflects the sophisticated engineering required to generate and control a stable microwave plasma.

Ongoing Operational and Maintenance Expenses

The costs do not stop after installation. MPCVD systems consume large amounts of power and require a continuous supply of high-purity process gases, which can be expensive. Furthermore, routine maintenance and the replacement of parts are necessary to ensure reliable operation.

The Operational Burden: Complexity and Precision

MPCVD is not a "set and forget" technology. It demands constant oversight and a deep understanding of the underlying physical and chemical processes.

Requirement for Deep Expertise

Operating an MPCVD system effectively requires highly skilled engineers or technicians. These operators must be able to develop recipes, troubleshoot issues, and interpret process data to achieve the desired film properties.

Extreme Process Sensitivity

The quality of the deposited material is acutely sensitive to a range of parameters, including temperature, pressure, microwave power, and gas flow rates. Any unplanned deviation in these variables can lead to defects in the film, such as poor adhesion, incorrect crystal structure, or impurities.

Substrate Compatibility and Preparation

The material being deposited must be compatible with the substrate it is grown on. Many applications require careful and often multi-step surface preparation of the substrate to ensure the deposited film will adhere properly and grow with the desired quality.

Understanding the Trade-offs: Safety and Environmental Risks

The powerful chemistry that makes MPCVD effective also introduces significant safety and environmental considerations that must be proactively managed.

Handling of Toxic and Reactive Gases

The chemical vapor deposition process often utilizes gases that are toxic, flammable, or highly reactive. Storing and handling these materials requires stringent safety measures, specialized equipment, and comprehensive personnel training to prevent accidents.

Management of Hazardous Byproducts

The chemical reactions inside the chamber can generate hazardous byproducts. These cannot simply be vented into the atmosphere. An effective exhaust and waste management system is essential to neutralize these byproducts, ensuring both operator safety and environmental compliance.

Making an Informed Decision on MPCVD

Evaluating MPCVD requires balancing its unique capabilities against its significant operational demands. Your decision should be guided by your primary objective.

- If your primary focus is cutting-edge material synthesis (e.g., diamond electronics): The high cost and complexity are often justifiable risks for achieving material properties that other methods cannot produce.

- If your primary focus is high-volume or cost-sensitive production: You must rigorously model the total cost of ownership, including maintenance, consumables, and specialized labor, to ensure economic viability.

- If your primary focus is process safety and compliance: A comprehensive safety plan for handling hazardous gases and managing waste streams must be a non-negotiable prerequisite to any investment.

By understanding these challenges upfront, you can strategically invest the necessary resources to unlock the full potential of this powerful technology.

Summary Table:

| Challenge Category | Key Issues |

|---|---|

| Financial | High upfront equipment costs, ongoing operational and maintenance expenses |

| Operational | Need for deep expertise, extreme process sensitivity, substrate compatibility |

| Safety & Environmental | Handling toxic/reactive gases, management of hazardous byproducts |

Facing MPCVD challenges? KINTEK can help! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions like CVD/PECVD Systems tailored for diverse laboratories. Our strong deep customization capability ensures precise fit for your unique experimental needs, helping you overcome costs, complexity, and safety issues. Contact us today to enhance your material synthesis process!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

People Also Ask

- Why is maintaining gas pipelines important in MPCVD equipment? Ensure Purity and Safety in Crystal Growth

- Why is keeping maintenance records important for MPCVD equipment? Ensure Reliability and Quality in Crystal Growth

- What are some applications of MPCVD? Unlock High-Purity Diamond for Advanced Engineering

- How is CVD classified based on physical characteristics of vapor? Explore AACVD and DLICVD Methods

- Why is the temperature control system important in MPCVD equipment? Ensure Precise Diamond Growth and Process Stability