In short, Microwave Plasma Chemical Vapor Deposition (MPCVD) is used to create high-purity diamond and other advanced materials for a wide range of demanding applications. Its uses span everything from industrial cutting tools and thermal management solutions to next-generation optical windows, advanced electronics, and biomedical devices. The technology's ability to produce high-quality, contamination-free crystalline films is the primary reason for its adoption in these fields.

The true value of MPCVD lies not just in its ability to create diamond, but in its method. By using an electrode-less plasma process, it delivers exceptionally high-purity materials with consistency and scalability, unlocking applications that were previously impossible or cost-prohibitive.

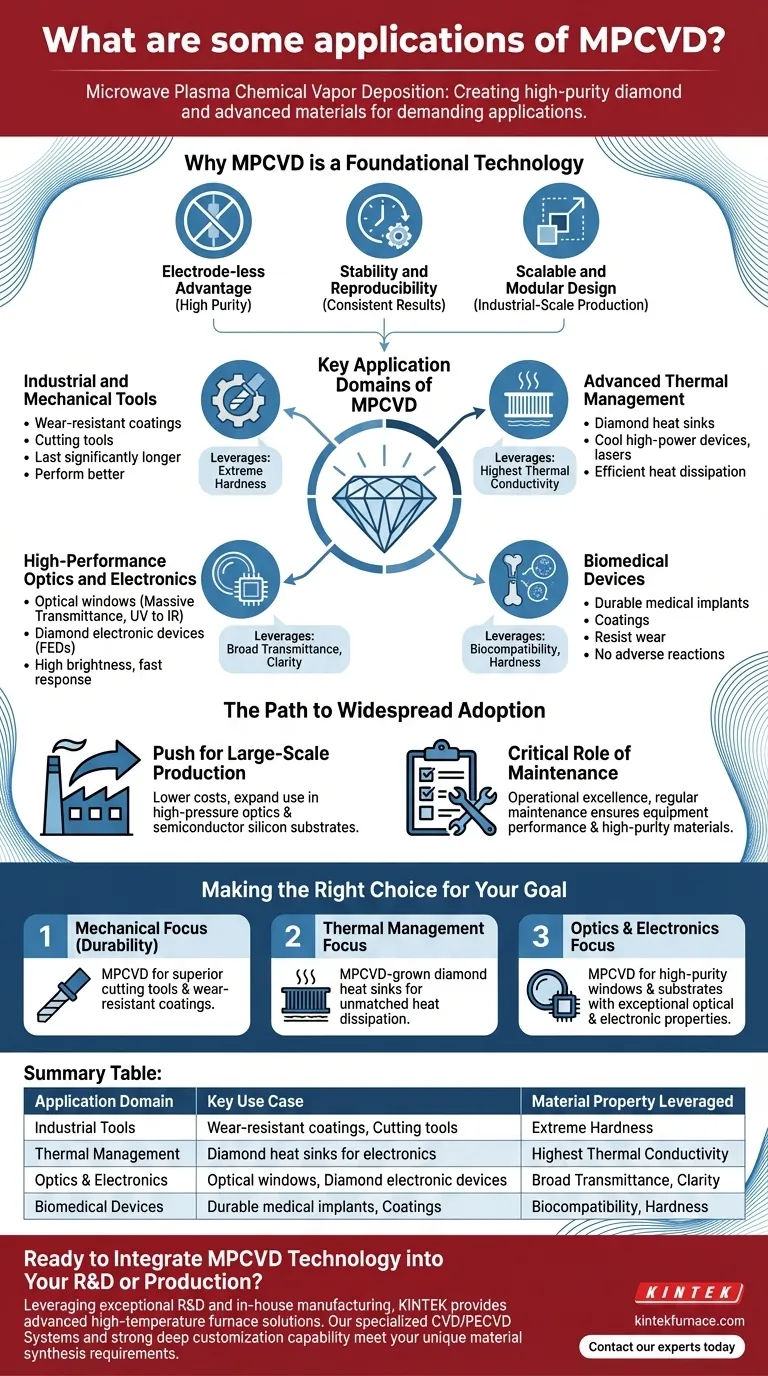

Why MPCVD is a Foundational Technology

Before listing the applications, it's crucial to understand what makes MPCVD so effective. The method's core advantages directly enable its diverse uses.

The Electrode-less Advantage

Unlike other deposition methods, MPCVD systems do not use internal electrodes. This design eliminates a major source of contamination, resulting in films of exceptionally high purity and quality.

Stability and Reproducibility

MPCVD processes are remarkably stable, allowing for continuous deposition over very long periods. This ensures consistent, reproducible results, which is critical for manufacturing high-performance components at scale.

Scalable and Modular Design

The technology is inherently modular and can be scaled to accommodate larger substrates. This adaptability makes MPCVD viable not just for research but also for industrial-scale production, such as coating large silicon wafers for the semiconductor industry.

Key Application Domains of MPCVD

The unique properties of materials grown via MPCVD—particularly diamond's hardness, thermal conductivity, and optical clarity—drive its use across several key sectors.

Industrial and Mechanical Tools

The extreme hardness of MPCVD diamond makes it ideal for wear-resistant coatings and cutting tools. These tools last significantly longer and perform better than traditional alternatives, especially when machining hard or abrasive materials.

Advanced Thermal Management

Diamond has the highest thermal conductivity of any known material. This property is leveraged in diamond heat sinks, which are used to cool high-power electronic devices, lasers, and other components where efficient heat dissipation is critical for performance and reliability.

High-Performance Optics and Electronics

MPCVD is used to grow high-quality single-crystal diamonds for optical windows. These windows offer a massive transmittance spectrum (from UV to infrared) and superior clarity, making them vital for specialized imaging systems and high-power lasers.

Furthermore, these properties are essential for diamond electronic devices, including Cold Cathode Field Emission Displays (FEDs), which benefit from high brightness, excellent resolution, and fast response times.

Biomedical Devices

The inert and biocompatible nature of diamond, combined with its hardness, makes it an excellent material for biomedical devices and coatings. It can be used for durable medical implants that resist wear and do not cause adverse reactions within the body.

The Path to Widespread Adoption

While powerful, the successful implementation of MPCVD is not without practical considerations. The technology is advancing quickly, but its potential is tied to process maturity and operational discipline.

The Push for Large-Scale Production

Ongoing advancements in MPCVD technology and synthesis techniques are making the mass production of large, high-quality single-crystal diamonds a near-term reality. This will lower costs and further expand its use in demanding fields like high-pressure optics and as large-size silicon substrates in the semiconductor industry.

The Critical Role of Maintenance

Realizing the full potential of MPCVD requires a commitment to operational excellence. Regular and precise maintenance is crucial to ensure the equipment operates normally, maintains performance, and consistently produces the high-purity crystalline materials required for advanced applications.

Making the Right Choice for Your Goal

Understanding MPCVD's capabilities allows you to align them with your specific technical objective.

- If your primary focus is mechanical performance and durability: MPCVD is your solution for creating superior cutting tools and wear-resistant coatings with unparalleled hardness.

- If your primary focus is thermal management: MPCVD-grown diamond heat sinks offer an unmatched solution for dissipating heat from high-power density electronics.

- If your primary focus is next-generation optics or electronics: MPCVD enables the creation of high-purity diamond windows and substrates with exceptional optical and electronic properties.

MPCVD is the key enabling technology for manufacturing the ultra-pure, high-performance materials that define the next frontier of engineering.

Summary Table:

| Application Domain | Key Use Case | Material Property Leveraged |

|---|---|---|

| Industrial Tools | Wear-resistant coatings, Cutting tools | Extreme Hardness |

| Thermal Management | Diamond heat sinks for electronics | Highest Thermal Conductivity |

| Optics & Electronics | Optical windows, Diamond electronic devices | Broad Transmittance, Clarity |

| Biomedical Devices | Durable medical implants, Coatings | Biocompatibility, Hardness |

Ready to Integrate MPCVD Technology into Your R&D or Production?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including specialized CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique material synthesis requirements, whether for R&D prototyping or industrial-scale production of high-purity diamond films.

Contact our experts today to discuss how our MPCVD solutions can help you achieve superior material performance and drive your innovations forward.

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- Why is keeping maintenance records important for MPCVD equipment? Ensure Reliability and Quality in Crystal Growth

- What are some challenges associated with MPCVD? Overcome High Costs and Complexity for Diamond Synthesis

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth