In short, only highly trained and certified professionals should perform maintenance on MPCVD equipment. The complexity of these systems—which integrate high-power microwaves, high-vacuum environments, and hazardous process gases—creates significant risk. Any maintenance attempted by non-specialists can easily lead to costly equipment damage, compromised material quality, and severe safety incidents.

Attempting to save costs with unqualified maintenance is a critical mistake. The true goal of MPCVD maintenance is not just to fix broken parts, but to preserve the extreme purity of the process environment and manage inherent operational hazards, both of which demand specialized expertise.

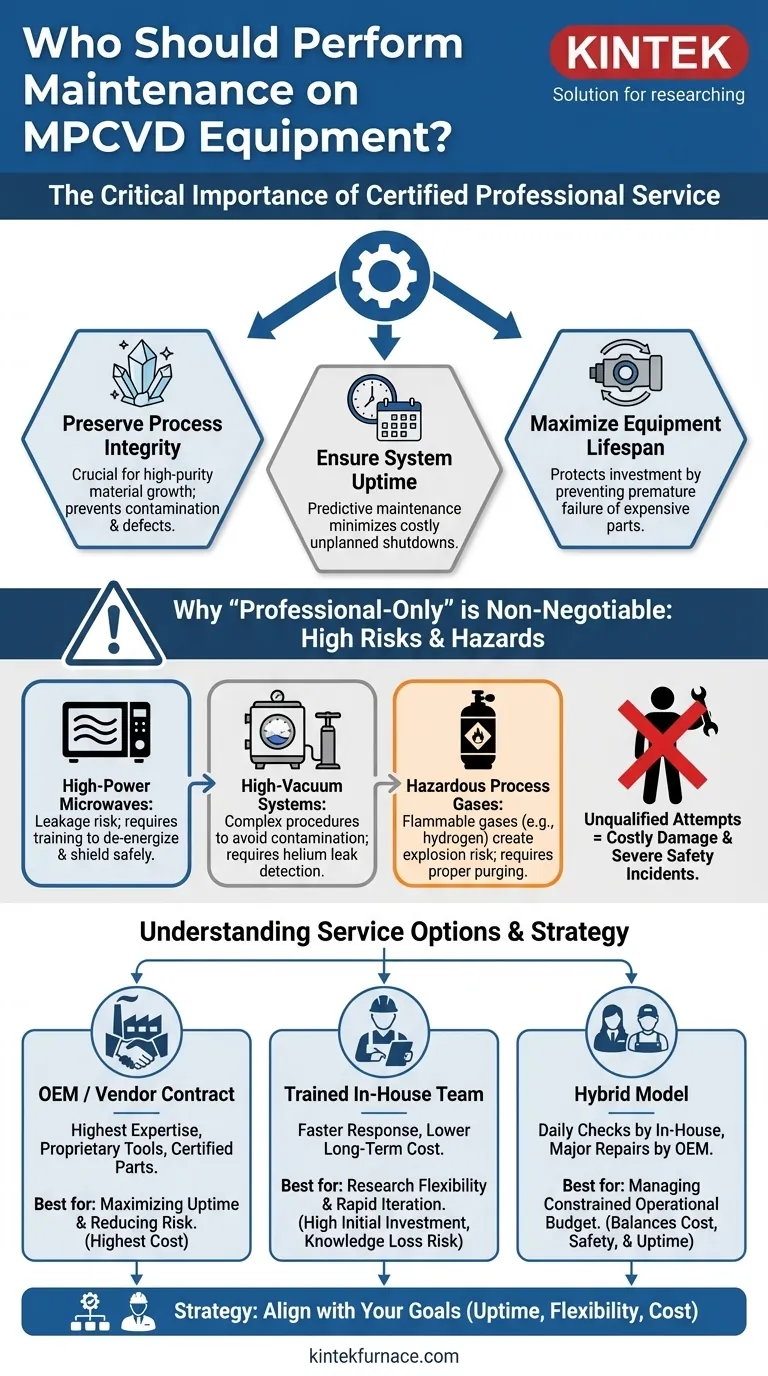

The Core Principles of MPCVD Maintenance

Effective maintenance is fundamental to the value of your MPCVD system. It moves beyond simple repairs and becomes a strategic function that directly impacts your operational success.

Preserving Process Integrity

Microwave Plasma Chemical Vapor Deposition (MPCVD) is a process of atomic-level precision. The goal is to grow high-purity crystal materials, and the slightest contamination can introduce defects, ruining an entire growth run.

Proper maintenance ensures the vacuum chamber remains pristine. It is about preventing contaminants like dust, oils, and atmospheric leaks from entering the system and compromising the quality of your final product.

Ensuring System Uptime

Unplanned downtime on capital equipment like an MPCVD system is incredibly expensive. It halts production, delays research, and consumes valuable engineering resources for troubleshooting.

A scheduled, professional maintenance program is predictive. It identifies and addresses potential failure points before they lead to a system shutdown, ensuring consistent and reliable operation.

Maximizing Equipment Lifespan

MPCVD systems contain expensive, long-lead-time components like microwave generators, vacuum pumps, and custom-designed reactor chambers.

Regular, qualified maintenance protects this investment. It ensures these critical parts operate within their specified parameters, preventing premature failure and extending the overall life of the equipment.

Why "Professional-Only" Is a Non-Negotiable Rule

The mandate for professional service is not an arbitrary guideline; it is rooted in the fundamental technologies that make MPCVD possible. Each subsystem presents a unique and significant hazard.

The Hazard of High-Power Microwaves

MPCVD systems use thousands of watts of microwave power to generate plasma. Improperly sealed waveguides or chambers can leak this radiation, posing a serious health risk to personnel.

Only trained technicians understand how to safely de-energize these systems, use microwave detectors to ensure a safe work area, and properly reassemble components to maintain shielding integrity.

The Complexity of High-Vacuum Systems

The system's high-vacuum environment is essential for purity. Maintenance often involves opening the chamber, which requires specific protocols to avoid contamination and damage to sealing surfaces.

Professionals are trained in tasks like replacing O-rings, cleaning flanges, and using helium leak detectors to find and fix microscopic leaks that would otherwise be invisible—and catastrophic to the process.

The Danger of Process Gases

These systems use a mixture of gases, including highly flammable hydrogen, which creates an explosion risk if not handled correctly.

A professional technician is trained in the proper procedures for purging gas lines, checking for leaks in fittings and regulators, and safely managing the entire gas delivery subsystem to prevent a potentially disastrous failure.

Understanding the Trade-offs: In-House vs. OEM Service

Choosing who performs the maintenance involves a strategic decision between developing an in-house team and relying on the original equipment manufacturer (OEM).

The Case for OEM/Vendor Contracts

Engaging the equipment manufacturer for service provides the highest level of expertise. They have access to proprietary diagnostic software, updated procedures, and a guaranteed supply of certified parts.

While this is often the most expensive option, it transfers much of the risk and liability to the vendor and is typically the fastest way to resolve complex issues.

The Case for a Trained In-House Team

Developing an internal maintenance capability can reduce long-term costs and improve response times for routine issues. An on-site expert can handle first-level troubleshooting and minor preventative tasks immediately.

However, this requires a significant upfront investment in factory training, certification, and specialized tools. It also carries the risk of knowledge loss if that key person leaves the organization.

The Hybrid Model: A Practical Solution

Most facilities find success with a hybrid approach. An in-house team is trained to handle daily operational checks, such as inspecting the exhaust system for blockages or listening for unusual pump noises.

For all major preventative maintenance, internal chamber cleaning, and complex repairs, the facility relies on a service contract with the OEM. This balances cost, safety, and uptime effectively.

Structuring Your MPCVD Maintenance Strategy

To build a robust strategy, align your approach with your primary operational goals.

- If your primary focus is maximizing uptime and production yield: A comprehensive service contract with the equipment manufacturer (OEM) is the most reliable path to ensure performance and minimize risk.

- If your primary focus is research flexibility and rapid iteration: Investing in factory training for a dedicated in-house technician can provide the speed needed for routine adjustments and first-level diagnostics.

- If your primary focus is managing a constrained operational budget: A hybrid model is your best option; use in-house staff for documented, non-invasive checks while reserving funds for critical OEM service calls.

Ultimately, a well-planned maintenance strategy transforms your MPCVD system from a complex liability into a predictable, high-performance asset.

Summary Table:

| Maintenance Aspect | Key Consideration |

|---|---|

| Safety | High-power microwaves, hazardous gases, and vacuum systems require expert handling to avoid risks. |

| Process Integrity | Prevents contamination for high-purity crystal growth, preserving material quality. |

| Uptime & Lifespan | Reduces downtime and extends equipment life through predictive maintenance. |

| Service Options | Choose OEM, in-house, or hybrid models based on uptime, flexibility, or cost goals. |

Ensure your MPCVD system operates safely and efficiently with KINTEK's expert solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how we can enhance your maintenance strategy and deliver reliable performance!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- In which industries is the microwave plasma chemical vapor deposition system commonly used? Unlock High-Purity Material Synthesis

- What factors influence the quality of diamond deposition in the MPCVD method? Master the Critical Parameters for High-Quality Diamond Growth

- What are the key advantages of MPCVD in diamond synthesis? Achieve High-Purity, Scalable Diamond Production

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth