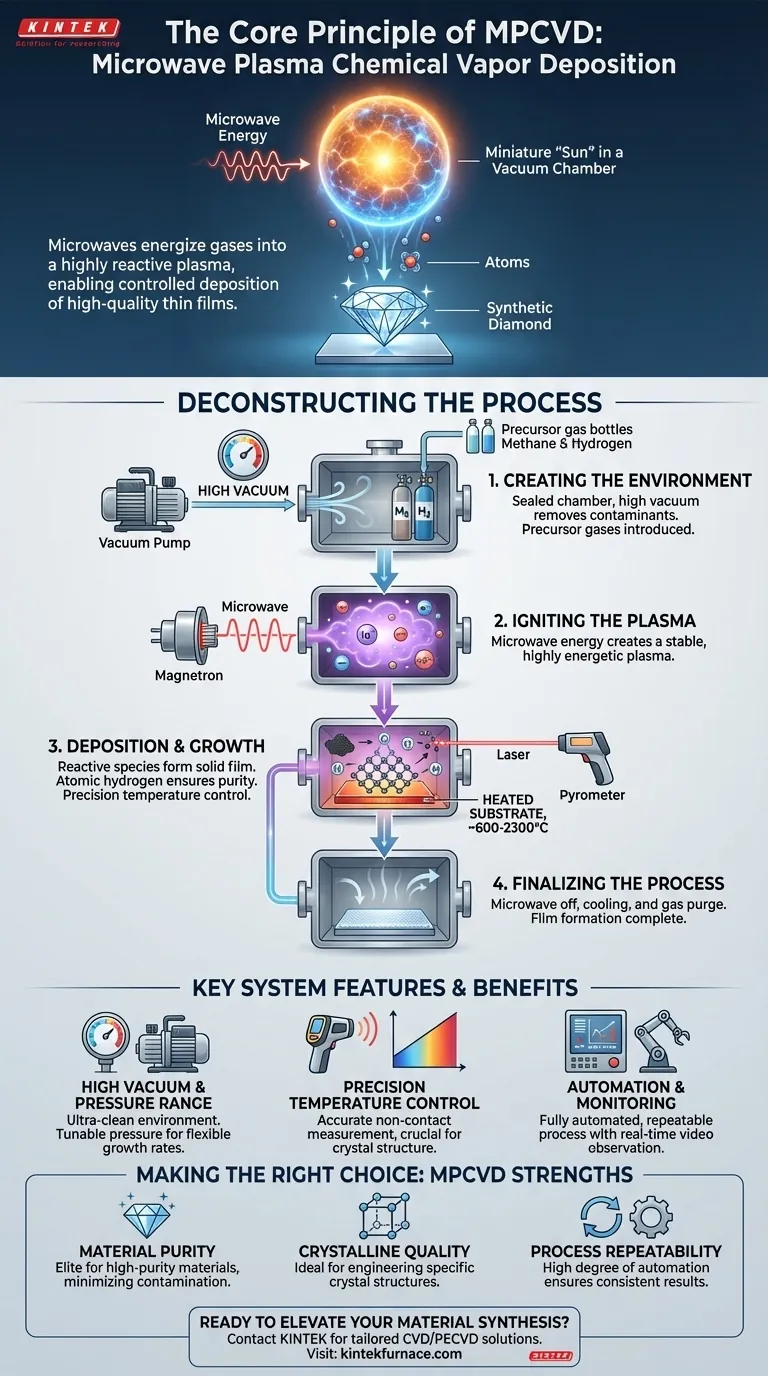

At its core, the basic principle of a Microwave Plasma Chemical Vapor Deposition (MPCVD) system is to use microwave energy to excite precursor gases into a plasma state. This highly reactive plasma then enables the controlled deposition of a solid thin film, such as synthetic diamond, onto a substrate.

The system essentially creates a highly controlled, miniature "sun" in a vacuum chamber. Microwaves energize specific gases into a plasma, which then breaks down and deposits atoms onto a surface to grow exceptionally pure, high-quality materials like diamond films and nanotubes.

Deconstructing the MPCVD Process

To truly understand the principle, it's best to break it down into the distinct operational steps. The entire process is a carefully choreographed sequence inside a highly controlled environment.

Step 1: Creating the Environment (Vacuum & Precursors)

First, the reaction chamber, typically made of metal to minimize contamination, is sealed and pumped down to a high vacuum. This step is critical because it removes atmospheric gases like oxygen and nitrogen, which would otherwise interfere with the chemical reactions and contaminate the final film.

Once the vacuum is established, a precise mixture of gaseous precursors is introduced into the chamber. For growing diamond, this mixture is typically methane (the carbon source) and hydrogen.

Step 2: Igniting the Plasma (Microwave Energy)

Microwaves are then directed into the chamber. This focused energy is absorbed by the gas molecules, stripping electrons from their atoms and creating a glowing, ionized gas known as a plasma.

This plasma is a highly energetic "soup" of ions, electrons, and reactive neutral species (like atomic hydrogen and carbon radicals). Maintaining a stable plasma is essential for ensuring the film grows uniformly across the entire substrate.

Step 3: Deposition and Growth (Film Formation)

The substrate, placed within the plasma, is heated to a very specific, high temperature. The reactive species created in the plasma travel to the substrate's surface and "stick" to it, forming a solid layer.

For diamond growth, the high concentration of atomic hydrogen in the plasma plays a dual role: it selectively etches away any non-diamond carbon (like graphite) that forms, ensuring a pure diamond film is grown. Precision temperature control, often measured with a non-contact pyrometer, is paramount for achieving the desired crystal structure.

Step 4: Finalizing the Process (Cooling & Purging)

After the desired film thickness is achieved, the microwave power is turned off, extinguishing the plasma. The system is then carefully cooled down, and any unreacted precursor gases are purged from the chamber, leaving behind the newly formed film on the substrate.

Understanding the System's Key Features

The effectiveness of an MPCVD system comes from several key design features that enable precise control over the growth process.

High Vacuum & Wide Pressure Range

A high vacuum ensures an ultra-clean starting environment. The ability to operate over a wide pressure range (e.g., 6-500 Torr) gives operators the flexibility to tune the process, often trading a higher growth rate at higher pressures for different film properties.

Precision Temperature Measurement

Material properties are critically dependent on temperature. An MPCVD system uses tools like a two-wave pyrometer to measure temperature accurately (from 600-2300°C) without physically touching the sample. This control is what allows for the growth of specific materials, from nanocrystalline to single-crystal diamond.

Automation and Monitoring

Modern systems are typically fully automated to ensure that process parameters (pressure, temperature, gas flow, microwave power) are perfectly controlled and repeatable. In-chamber video monitoring also allows technicians to observe the plasma and sample growth in real time.

Making the Right Choice for Your Goal

Understanding the principle of MPCVD helps you recognize where its strengths lie. The technology is not just about making a film; it's about making a specific, high-performance film.

- If your primary focus is material purity: MPCVD is an elite choice for growing materials like synthetic diamond because the vacuum and metal chamber design drastically reduce contamination.

- If your primary focus is crystalline quality: The precise, independent control over plasma, temperature, and pressure makes MPCVD ideal for engineering specific crystal structures, from monocrystalline diamond to carbon nanotubes.

- If your primary focus is process repeatability: The high degree of automation in MPCVD systems ensures that complex recipes can be run identically time after time, which is critical for both research and production.

Ultimately, the MPCVD process empowers engineers and scientists to construct materials atom by atom in a highly controlled and pure environment.

Summary Table:

| Step | Process | Key Elements |

|---|---|---|

| 1 | Environment Setup | High vacuum, precursor gases (e.g., methane, hydrogen) |

| 2 | Plasma Ignition | Microwave energy, stable plasma formation |

| 3 | Deposition & Growth | Substrate heating, reactive species, temperature control |

| 4 | Process Finalization | Cooling, purging of gases |

Ready to elevate your material synthesis with advanced MPCVD technology? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our expertise can help you achieve superior film deposition and process repeatability!

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- In which industries is the microwave plasma chemical vapor deposition system commonly used? Unlock High-Purity Material Synthesis

- How does MPCVD achieve high growth rates for diamond synthesis? Unlock Rapid, High-Quality Diamond Growth

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- What are the key advantages of MPCVD in diamond synthesis? Achieve High-Purity, Scalable Diamond Production

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics