In the field of advanced material deposition, Microwave Plasma Chemical Vapor Deposition (MPCVD) distinguishes itself from methods like Hot Filament CVD (HFCVD) and plasma torch by offering unparalleled control over purity and film uniformity. Its core advantage lies in using clean, contactless microwaves to generate a stable, high-density plasma. This avoids the contamination inherent in HFCVD and provides greater homogeneity over large areas compared to the more localized energy of a plasma torch.

The fundamental difference is not merely the energy source, but how that energy is delivered. MPCVD's use of contained microwaves provides a clean, uniform, and highly controlled environment for film growth, leading to superior material properties that other methods struggle to consistently replicate.

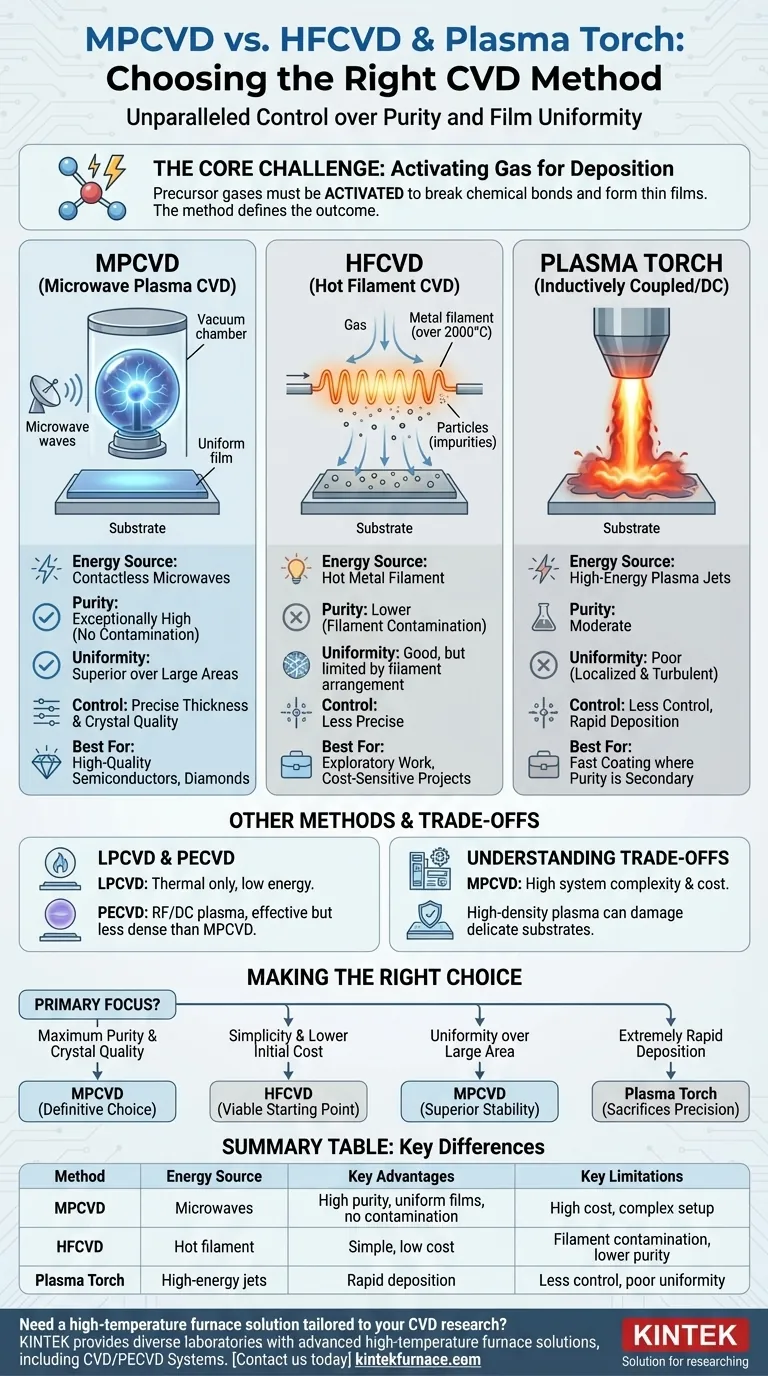

The Core Challenge: Activating Gas for Deposition

Chemical Vapor Deposition (CVD) is a process where precursor gases are introduced into a chamber to react and form a solid thin film on a substrate. For this reaction to occur, the gases must be "activated" with a significant amount of energy.

The Role of Energy in CVD

The primary goal of any CVD energy source is to break the chemical bonds within the precursor gases. This creates highly reactive species, radicals, and ions that are the building blocks of the thin film.

The Defining Factor: Method of Activation

The specific method used to supply this energy is what defines each type of CVD. This choice directly impacts the purity, quality, uniformity, and potential applications of the resulting film.

A Direct Comparison: MPCVD vs. Key Alternatives

While all CVD techniques share a common goal, their mechanisms lead to vastly different outcomes. MPCVD is often considered the benchmark for high-purity applications, especially for materials like diamond.

Microwave Plasma CVD (MPCVD): Purity and Control

MPCVD uses microwaves focused into a vacuum chamber to create a dense, stable ball of plasma. The precursor gases flow through this plasma and are broken down efficiently.

Because the energy is delivered wirelessly via microwaves, there are no electrodes or filaments inside the chamber that can degrade and contaminate the film. This results in exceptionally high-purity films with precise control over thickness and crystal quality across large areas.

Hot Filament CVD (HFCVD): Simplicity at a Cost

HFCVD uses a much simpler approach: a metal wire (the filament), typically made of tungsten or tantalum, is heated to over 2000°C. Gases passing over this hot filament decompose and deposit onto the substrate.

While simpler and less expensive to set up, HFCVD's primary drawback is filament contamination. The hot wire inevitably evaporates or reacts with the process gases, introducing impurities into the final film and limiting its quality and performance.

Plasma Torch (Inductively Coupled/DC): High Energy, Less Precision

Plasma torches generate extremely hot, high-energy plasma jets. This method is effective for rapid deposition but offers less control over the process.

Compared to the large, stable, and uniform plasma ball in an MPCVD system, a plasma torch is more localized and turbulent. This makes it challenging to achieve the same level of film homogeneity and consistency, especially over a large substrate.

Other Methods: LPCVD and PECVD

Low-Pressure CVD (LPCVD) relies solely on thermal energy in a low-pressure environment and lacks plasma enhancement, making it less suitable for high-performance films that require significant activation energy.

Plasma-Enhanced CVD (PECVD) uses radio frequency (RF) or direct current (DC) energy to create plasma. While effective, MPCVD generally offers a higher-density plasma and superior control, leading to higher-quality films for the most demanding applications.

Understanding the Trade-offs of MPCVD

No technology is without its limitations. MPCVD's precision and quality come with specific operational considerations that are critical for decision-making.

System Complexity and Cost

MPCVD systems are sophisticated and require a significant capital investment. The microwave generators, waveguides, and resonant cavities are more complex and expensive to design, build, and maintain compared to a simple HFCVD setup.

Substrate Sensitivity

The high-density plasma generated in an MPCVD system, while excellent for creating reactive species, can also be damaging to certain substrates. Delicate materials, such as some polymers or organic electronics, may not withstand the intense plasma environment.

Making the Right Choice for Your Application

Selecting the appropriate CVD method requires aligning the technique's strengths and weaknesses with your project's primary objective.

- If your primary focus is maximum purity and crystal quality: MPCVD is the definitive choice, especially for advanced semiconductor or optical applications like lab-grown diamonds.

- If your primary focus is simplicity and lower initial cost for exploratory work: HFCVD can be a viable starting point, provided you can tolerate potential film contamination.

- If your primary focus is achieving uniform film properties over a large area: MPCVD's stable and widespread plasma field is superior to the more localized nature of other plasma sources.

- If your primary focus is extremely rapid deposition where ultimate purity is secondary: A plasma torch might be considered, though it sacrifices the precision and uniformity of MPCVD.

Ultimately, selecting the right CVD method is a strategic decision that balances your required film quality against operational complexity and cost.

Summary Table:

| Method | Energy Source | Key Advantages | Key Limitations | Best For |

|---|---|---|---|---|

| MPCVD | Microwaves | High purity, uniform films, no contamination | High cost, complex setup | High-quality semiconductors, diamonds |

| HFCVD | Hot filament | Simple, low cost | Filament contamination, lower purity | Exploratory work, cost-sensitive projects |

| Plasma Torch | High-energy jets | Rapid deposition | Less control, poor uniformity | Fast coating where purity is secondary |

Need a high-temperature furnace solution tailored to your CVD research? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our expertise can enhance your material deposition processes and achieve superior results!

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What are the key advantages of MPCVD in diamond synthesis? Achieve High-Purity, Scalable Diamond Production

- Why is MPCVD considered a cornerstone of modern materials science and engineering? Unlock High-Purity Materials for Innovation

- In which industries is the microwave plasma chemical vapor deposition system commonly used? Unlock High-Purity Material Synthesis

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance

- What is the relationship between diamond growth rate and quality in the MPCVD method? Balancing Speed and Purity for Your Application