At its core, Microwave Plasma-Assisted Chemical Vapor Deposition (MPCVD) is a highly controlled manufacturing process that allows for the growth of exceptionally pure, low-stress carbon films with precisely tailored properties. By using microwave energy to create a stable plasma, MPCVD enables the atomic-level construction of materials like diamond, making it indispensable for advanced industrial and electronic applications where material perfection is non-negotiable.

The fundamental advantage of MPCVD is not just its ability to create carbon films, but its capacity for atomic-level control. This precision allows engineers to move beyond commodity materials and design films with specific, high-performance characteristics for demanding environments.

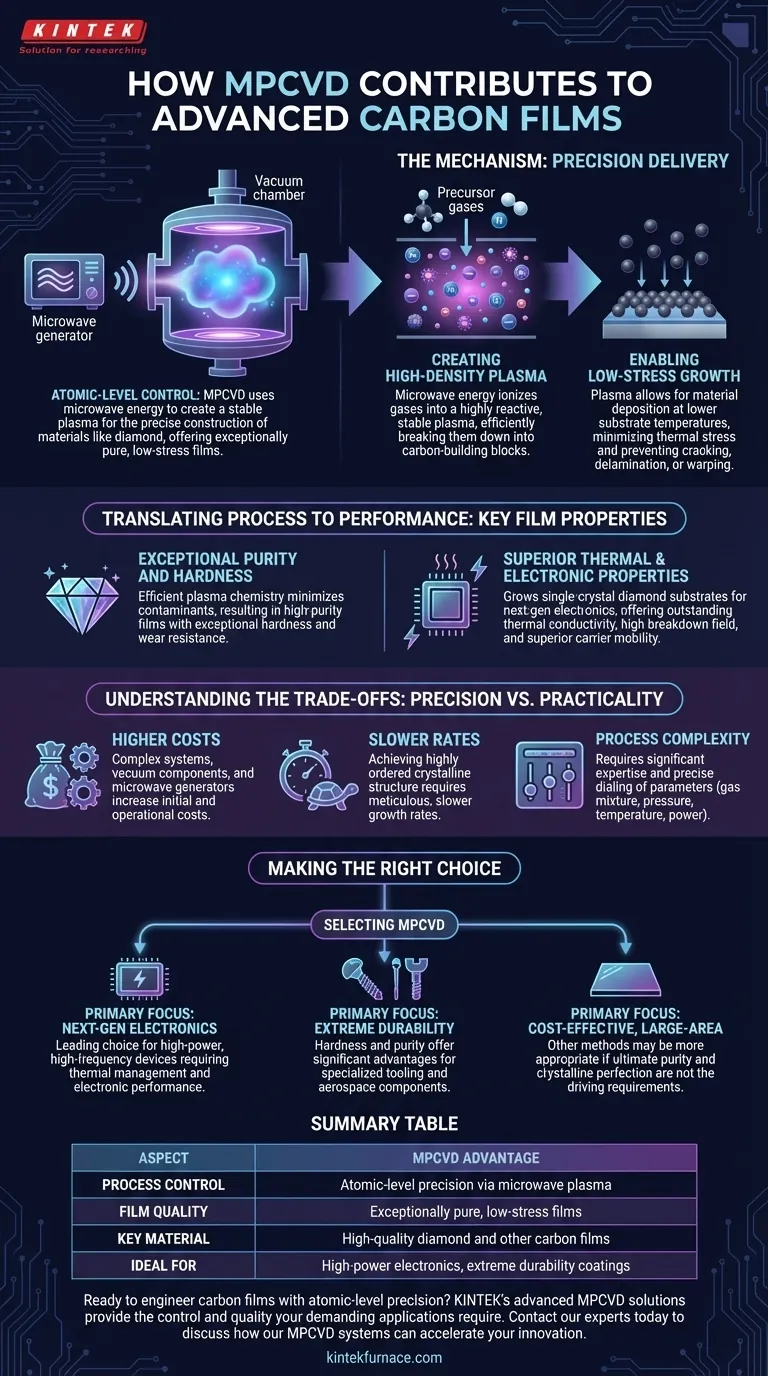

The Mechanism: How MPCVD Delivers Precision

The unique capabilities of MPCVD stem directly from its use of microwave energy to generate and sustain a chemical plasma. This approach provides a level of control that older deposition methods cannot match.

Creating a High-Density Plasma

MPCVD systems introduce precursor gases (like methane in a hydrogen carrier) into a vacuum chamber. Microwave energy is then focused into this chamber, ionizing the gas and creating a dense, stable plasma.

This plasma is a highly reactive soup of ions, electrons, and radicals. The high energy and stability of the microwave-generated plasma efficiently break down the precursor gases into their fundamental carbon-building blocks.

Enabling Low-Stress Growth

Unlike traditional thermal CVD, which relies on high heat alone, MPCVD's plasma allows for material deposition at significantly lower substrate temperatures.

This lower temperature minimizes thermal stress, preventing the film from cracking, delaminating, or warping. The result is a low-stress film that maintains its structural integrity and adheres strongly to the underlying substrate.

Translating Process to Performance: Key Film Properties

The controlled environment of MPCVD translates directly into superior material properties that unlock new technological possibilities.

Exceptional Purity and Hardness

The efficiency of the plasma chemistry ensures that unwanted contaminants and amorphous carbon phases are minimized. This results in high-purity films, particularly in the case of synthetic diamond, that exhibit exceptional hardness and wear resistance for industrial coatings.

Superior Thermal and Electronic Properties

For applications in advanced electronics, MPCVD is used to grow single-crystal diamond substrates. These materials possess outstanding properties that are critical for next-generation devices.

These properties include exceptional thermal conductivity for heat dissipation, a high breakdown field to handle high voltages, and superior carrier mobility for faster switching speeds. This enables high-frequency, high-power electronics with better performance and less energy loss.

Understanding the Trade-offs: Precision vs. Practicality

While MPCVD offers unparalleled quality, it is a specialized tool with specific trade-offs that are important to understand.

Higher Initial and Operational Costs

MPCVD systems are complex and require significant capital investment compared to simpler deposition technologies. The use of high-vacuum components, microwave generators, and precise gas control systems contributes to a higher cost of ownership.

Slower Deposition Rates

The very precision that makes MPCVD so valuable often necessitates slower growth rates. Achieving a highly ordered, crystalline structure like diamond is a meticulous process that cannot be rushed, making it less suitable for applications requiring high-volume, rapid coating.

Process Complexity

Operating an MPCVD system requires significant expertise. Dialing in the exact parameters—gas mixture, pressure, temperature, and microwave power—to achieve a specific film property is a complex task that demands a skilled operator.

Making the Right Choice for Your Application

Selecting MPCVD depends entirely on whether the performance benefits justify the investment.

- If your primary focus is next-generation electronics: MPCVD is the leading choice for creating high-power, high-frequency devices where thermal management and electronic performance are paramount.

- If your primary focus is extreme durability: For specialized tooling, medical implants, or aerospace components, the hardness and purity of MPCVD diamond films offer a significant performance advantage.

- If your primary focus is cost-effective, large-area coatings: Other methods like sputtering or thermal CVD may be more appropriate for applications where ultimate purity and crystalline perfection are not the driving requirements.

Ultimately, MPCVD empowers engineers to treat carbon films not as a simple coating, but as a designed material engineered for a specific purpose.

Summary Table:

| Aspect | MPCVD Advantage |

|---|---|

| Process Control | Atomic-level precision via microwave plasma |

| Film Quality | Exceptionally pure, low-stress films |

| Key Material | High-quality diamond and other carbon films |

| Ideal For | High-power electronics, extreme durability coatings |

Ready to engineer carbon films with atomic-level precision? KINTEK's advanced MPCVD solutions, backed by exceptional R&D and in-house manufacturing, provide the control and quality your demanding applications require. Whether you're developing next-generation electronics or need ultra-durable coatings, our expertise and deep customization capabilities are here to meet your unique experimental needs.

Contact our experts today to discuss how our MPCVD systems can accelerate your innovation.

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the key features of CVD tube furnaces for 2D material processing? Unlock Precision Synthesis for Superior Materials

- What are 2D heterostructures and how are they created using CVD tube furnaces? Unlock Atomic-Scale Material Engineering

- What are the advantages of CVD tube furnace sintering systems? Achieve Superior Material Control and Purity

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films