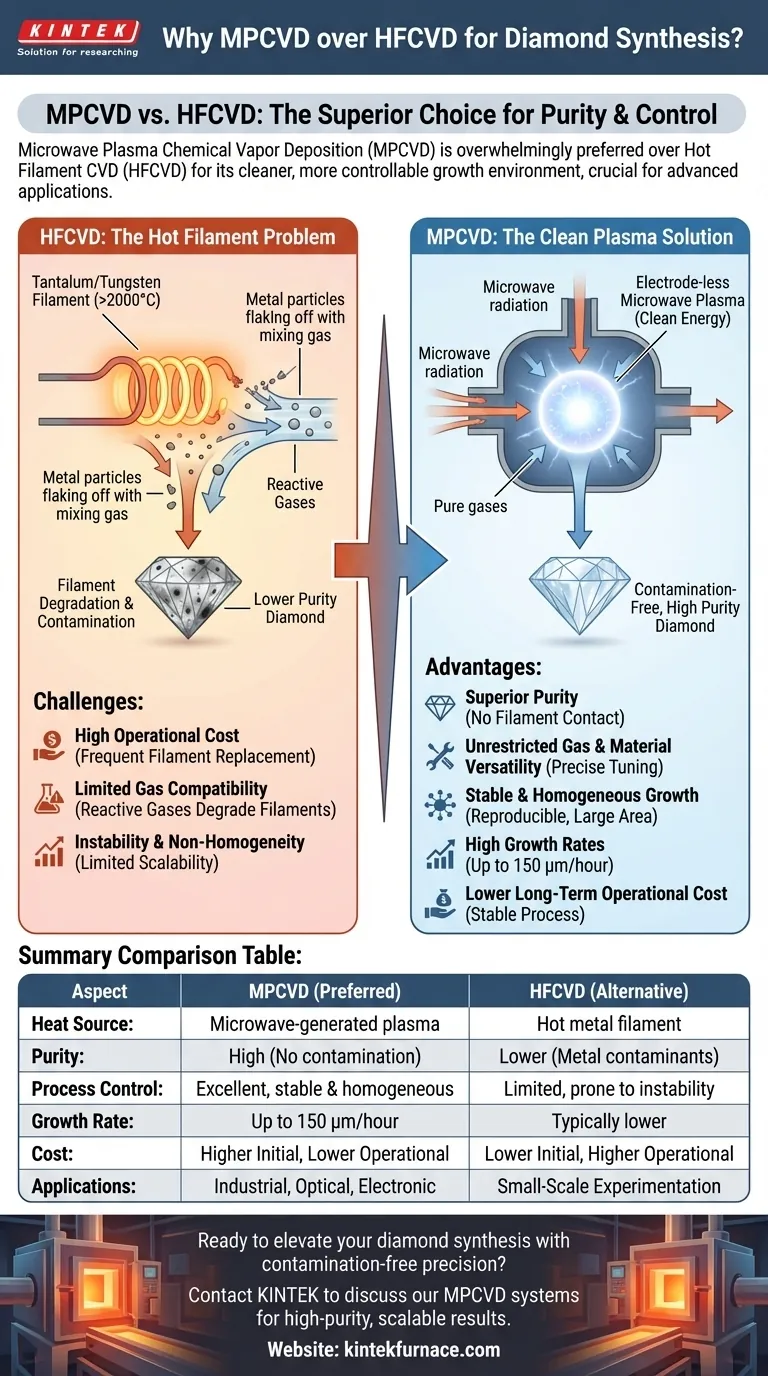

In the field of diamond synthesis, Microwave Plasma Chemical Vapor Deposition (MPCVD) is overwhelmingly preferred over Hot Filament CVD (HFCVD) because it offers a fundamentally cleaner and more controllable growth environment. MPCVD uses microwaves to generate a plasma, eliminating the hot metal filaments that are the primary source of contamination, process instability, and material limitations in the HFCVD method. This leads to higher-purity diamonds and greater manufacturing versatility.

The choice between these methods is a strategic one. While HFCVD offers simplicity, MPCVD provides the purity, control, and scalability essential for producing high-quality diamonds demanded by advanced industrial, optical, and electronic applications.

The Fundamental Difference: Heat Source and Purity

The core distinction between MPCVD and HFCVD lies in how they generate the energy needed to decompose precursor gases and grow diamond films. This single difference has profound implications for the quality of the final product.

HFCVD: The Hot Filament Problem

Hot Filament CVD operates by passing a current through a metal wire, typically made of tantalum or tungsten, heating it to over 2000°C. This hot filament heats the surrounding gases, breaking them down to create the reactive species needed for diamond growth.

The critical drawback is the filament itself. At such high temperatures and in a reactive chemical environment, the filament degrades over time. This process introduces metal contaminants directly into the diamond film, compromising its purity and performance.

MPCVD: The Clean Plasma Solution

MPCVD takes an entirely different approach. It uses microwaves to energize the gas mixture into a plasma, an ionized state of matter. This process is electrode-less, meaning the energy is transferred to the gas without any direct contact from a hot physical component.

By creating a "clean" plasma, MPCVD completely avoids the filament degradation and contamination inherent to the HFCVD method. This results in significantly higher-purity diamond films.

Why Process Control is Critical

The advantages of MPCVD extend beyond just purity. Its electrode-less design enables a level of process control and flexibility that HFCVD cannot match.

Unlocking Gas and Material Versatility

The metal filaments in HFCVD are sensitive to certain reactive gases, which can accelerate their degradation and shorten their lifespan. This sensitivity limits the types of chemical precursors that can be used, restricting the ability to tailor diamond properties.

MPCVD has no such limitation. It is compatible with a wide array of gases, allowing researchers and manufacturers to precisely tune the diamond's characteristics for specific needs, from optics to electronics.

Achieving Stable and Homogeneous Growth

The plasma generated in an MPCVD system is typically large, stable, and highly uniform. This stability allows for reproducible sample quality over long, continuous deposition runs.

Furthermore, the homogenous nature of the plasma ensures that the diamond film grows evenly across large substrate areas. This is crucial for industrial scalability and producing large, single-crystal diamonds.

Enabling High Growth Rates

MPCVD systems can achieve a high density of reactive species within the plasma. This enables very high growth rates, sometimes reaching up to 150 μm per hour, making the process more efficient for industrial production.

Understanding the Trade-offs

While MPCVD is superior for high-performance applications, it's important to understand the context where HFCVD might still be considered.

Initial Cost vs. Operational Cost

HFCVD systems are often simpler in design and can have a lower initial setup cost. This can make them attractive for small-scale academic research or exploratory work.

However, the ongoing operational cost of HFCVD is higher due to the need to frequently replace the consumable filaments. MPCVD, with its higher initial investment, proves more cost-effective for long-term, high-volume production due to its stability and lower maintenance.

System Complexity

An HFCVD reactor is mechanically and conceptually straightforward. In contrast, an MPCVD system requires more sophisticated components, such as a microwave generator, waveguides, and a precisely tuned reactor chamber, making it more complex to design and operate.

Making the Right Choice for Your Goal

Your choice of synthesis method should be dictated by your end goal for the diamond material.

- If your primary focus is high-purity industrial, optical, or electronic applications: MPCVD is the definitive choice due to its contamination-free process, superior control, and scalability.

- If your primary focus is lower-cost, small-scale experimentation where ultimate purity is not the top priority: HFCVD can be a viable starting point due to its simpler and less expensive initial setup.

Ultimately, the industry's preference for MPCVD reflects a strategic commitment to the precision, purity, and reproducibility required by modern high-performance diamond applications.

Summary Table:

| Aspect | MPCVD | HFCVD |

|---|---|---|

| Heat Source | Microwave-generated plasma | Hot metal filament |

| Purity | High, no filament contamination | Lower, due to metal contaminants |

| Process Control | Excellent, stable and homogeneous | Limited, prone to instability |

| Growth Rate | Up to 150 μm/hour | Typically lower |

| Cost | Higher initial, lower operational | Lower initial, higher operational |

| Applications | Industrial, optical, electronic | Small-scale experimentation |

Ready to elevate your diamond synthesis with contamination-free precision? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our MPCVD systems can deliver high-purity, scalable results for your industrial, optical, or electronic applications!

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What are the two main methods of synthetic diamond production? Discover HPHT vs. CVD for Lab-Grown Gems

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance

- What does CVD stand for and what is its primary function? Discover High-Purity Thin Film Deposition

- Can the reducing atmosphere be replaced with other gaseous mediums? Explore Advanced Surface Engineering Solutions

- How does the MPCVD process work to deposit diamond? A Guide to High-Purity Synthesis