The primary function of a Drop Tube Furnace (DTF) is to replicate the extreme thermal environment of industrial-scale boilers within a controlled laboratory setting. By subjecting pulverized coal or biomass particles to heating rates between $10^4$ and $10^5$ K/s, the DTF allows researchers to observe critical combustion phases—such as ignition, devolatilization, and char formation—under conditions that closely mimic real-world operations.

The Drop Tube Furnace is the definitive tool for studying fuel behavior under realistic thermal shock. Unlike standard laboratory methods that heat fuel slowly, the DTF captures the rapid physical and chemical changes that occur during the short residence times of actual industrial combustion.

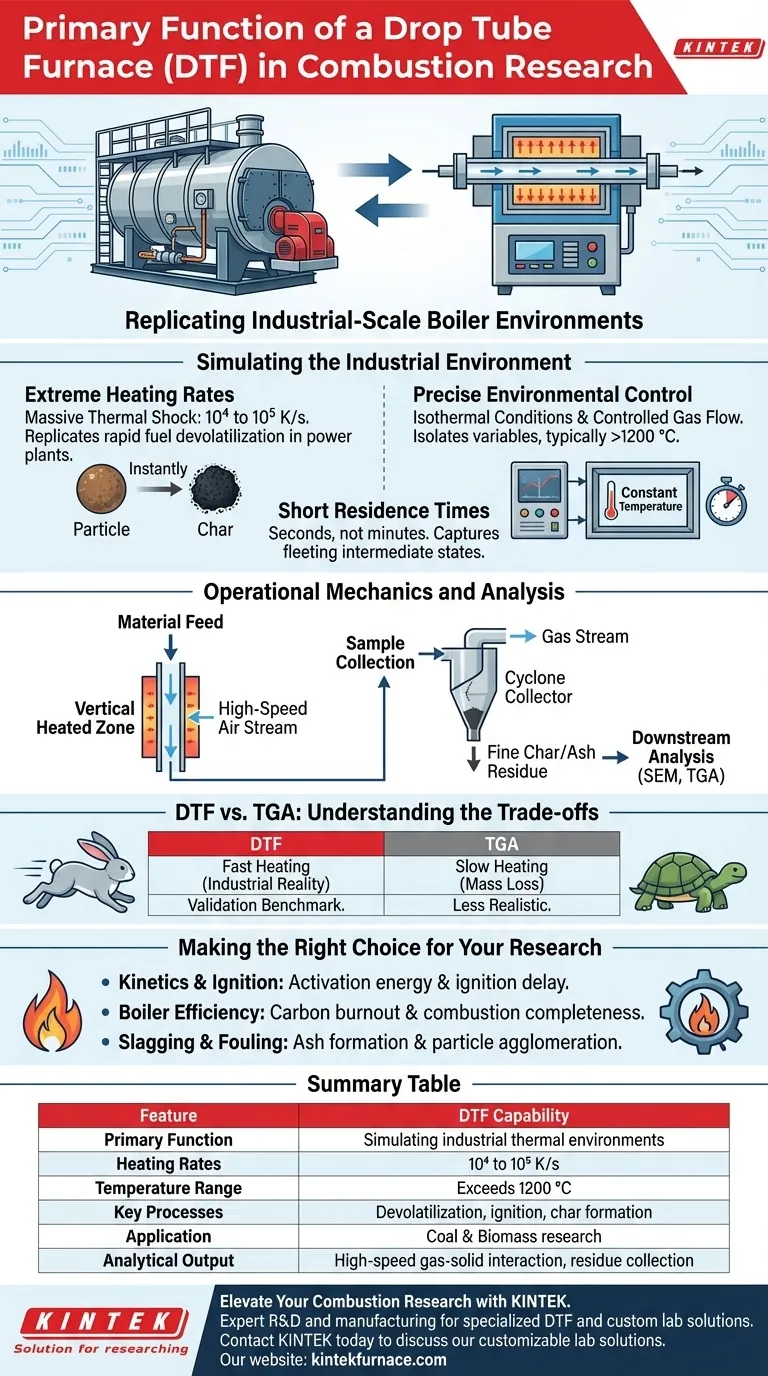

Simulating the Industrial Environment

Replicating Extreme Heating Rates

The defining characteristic of a DTF is its ability to generate massive thermal shock. Industrial boilers heat fuel almost instantly; the DTF matches this by achieving heating rates of $10,000$ to $100,000$ K/s.

This rapid heating is essential for accuracy. It ensures the fuel particles undergo devolatilization and structural changes exactly as they would in a power plant, rather than the gradual changes seen in slower devices.

Precise Environmental Control

While the heating is aggressive, the environment is strictly controlled. The DTF maintains isothermal conditions (constant temperature) and precise gas flow rates throughout the reactor.

This allows researchers to isolate specific variables. You can adjust the temperature (often exceeding 1200 °C) and the reactive gas composition to see exactly how these factors influence the fuel's behavior.

Short Residence Times

Real combustion happens in seconds, not minutes. The DTF is designed as a vertical reactor where particles fall through a heated zone, experiencing very short residence times.

This brief exposure prevents "over-baking" the samples. It captures the fleeting intermediate states of combustion, providing a snapshot of the fuel's transformation at specific moments in the process.

Operational Mechanics and Analysis

The Vertical Flow System

In a typical DTF setup, materials are fed into the top of a vertical tube and travel downward with a high-speed air stream. This ensures strictly gas-solid contact conditions comparable to suspension firing in boilers.

Sample Collection and Validation

The process does not end with burning; it ends with capture. Devices such as a Cyclone Collector use centrifugal force to separate fine char and ash from the gas stream.

These residues are critical for downstream analysis. Researchers use Scanning Electron Microscopy (SEM) and Thermogravimetric Analysis (TGA) on these samples to assess morphology and combustion completeness.

Understanding the Trade-offs

DTF vs. Thermogravimetric Analysis (TGA)

It is important to distinguish the DTF from TGA. TGA is excellent for measuring mass loss, but it typically operates at much slower heating rates that do not reflect industrial reality.

Therefore, the DTF serves as a validation benchmark. Data derived from the "slow" TGA must often be cross-referenced with "fast" DTF results to ensure the thermogravimetric indices remain relevant to actual boiler performance.

Complexity of Char Characterization

Because the DTF produces char that closely resembles industrial byproducts, the resulting material is complex.

Analyzing these samples requires sophisticated equipment. The rapid devolatilization creates porous, fragile structures that require careful handling during the collection phase to avoid altering the sample before analysis.

Making the Right Choice for Your Research

To maximize the value of a Drop Tube Furnace, align its capabilities with your specific research objectives:

- If your primary focus is Kinetics and Ignition: Use the DTF to determine the specific activation energy and ignition delay times under high heating rates, as these will differ significantly from slow-heating data.

- If your primary focus is Boiler Efficiency: Analyze the collected char residues to determine carbon burnout levels and validate if a specific fuel type will combust completely within the residence time of your target boiler.

- If your primary focus is Slagging and Fouling: utilize the DTF to study ash formation mechanisms and alkali metal release, specifically looking at how the high-temperature environment affects particle agglomeration.

The Drop Tube Furnace provides the only reliable method to observe the physics of industrial combustion on a laboratory scale.

Summary Table:

| Feature | Drop Tube Furnace (DTF) Capability |

|---|---|

| Primary Function | Simulating industrial thermal environments at laboratory scale |

| Heating Rates | $10^4$ to $10^5$ K/s (Extreme thermal shock) |

| Temperature Range | Typically exceeds 1200 °C (Isothermal control) |

| Key Processes | Devolatilization, ignition, and char formation |

| Application | Pulverized coal and biomass combustion research |

| Analytical Output | High-speed gas-solid interaction and residue collection |

Elevate Your Combustion Research with KINTEK

Precise data in fuel research depends on replicating the extreme conditions of industrial boilers. Backed by expert R&D and manufacturing, KINTEK offers specialized Drop Tube Furnaces (DTF), along with a full suite of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need to simulate high-velocity thermal shock or require a custom high-temperature solution tailored to your unique lab specifications, we have the engineering expertise to support your goals.

Ready to optimize your combustion analysis? Contact KINTEK today to discuss our customizable lab solutions with an expert.

Visual Guide

References

- Garikai T. Marangwanda, Daniel M. Madyira. Evaluating Combustion Ignition, Burnout, Stability, and Intensity of Coal–Biomass Blends Within a Drop Tube Furnace Through Modelling. DOI: 10.3390/en18061322

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why must a tube furnace be equipped with a nitrogen flow control system? Secure High-Quality Carbon Activation

- How does a Tube Furnace ensure structural consistency in Fe/MWCNT synthesis? Expert Control for Composite Quality

- What is the role of a three-zone tube furnace in the synthesis of single-crystal V2O5 nanosheets? Expert Insights

- What are the benefits of using tube furnaces in industrial processes? Achieve Precision and Control for Your Lab

- What are the main characteristics of horizontal tube furnaces? Optimize Your High-Temp Processing with Uniform Heating

- What materials can be melted in horizontal tube furnaces? Unlock precise high-temperature melting for metals, ceramics, and more

- What process conditions are provided by a horizontal tube furnace for AuNPs@MOF catalysts? Precise Thermal Control

- How does the injection probe in a Drop Tube Furnace ensure a high heating rate? Simulate Industrial Pyrolysis Expertly