The primary role of a three-zone tube furnace is to serve as the core infrastructure for controlled vapor phase growth. It facilitates this by providing precise, independent temperature regulation across distinct heating zones, which is physically necessary to decouple the management of precursor evaporation from the substrate reaction environment.

Core Takeaway Success in vapor phase synthesis relies on creating two distinct thermal environments within a single system. The three-zone furnace solves this by allowing you to generate specific vapor pressures for precursors in one zone while simultaneously maintaining different, ideal deposition temperatures for the substrate in another.

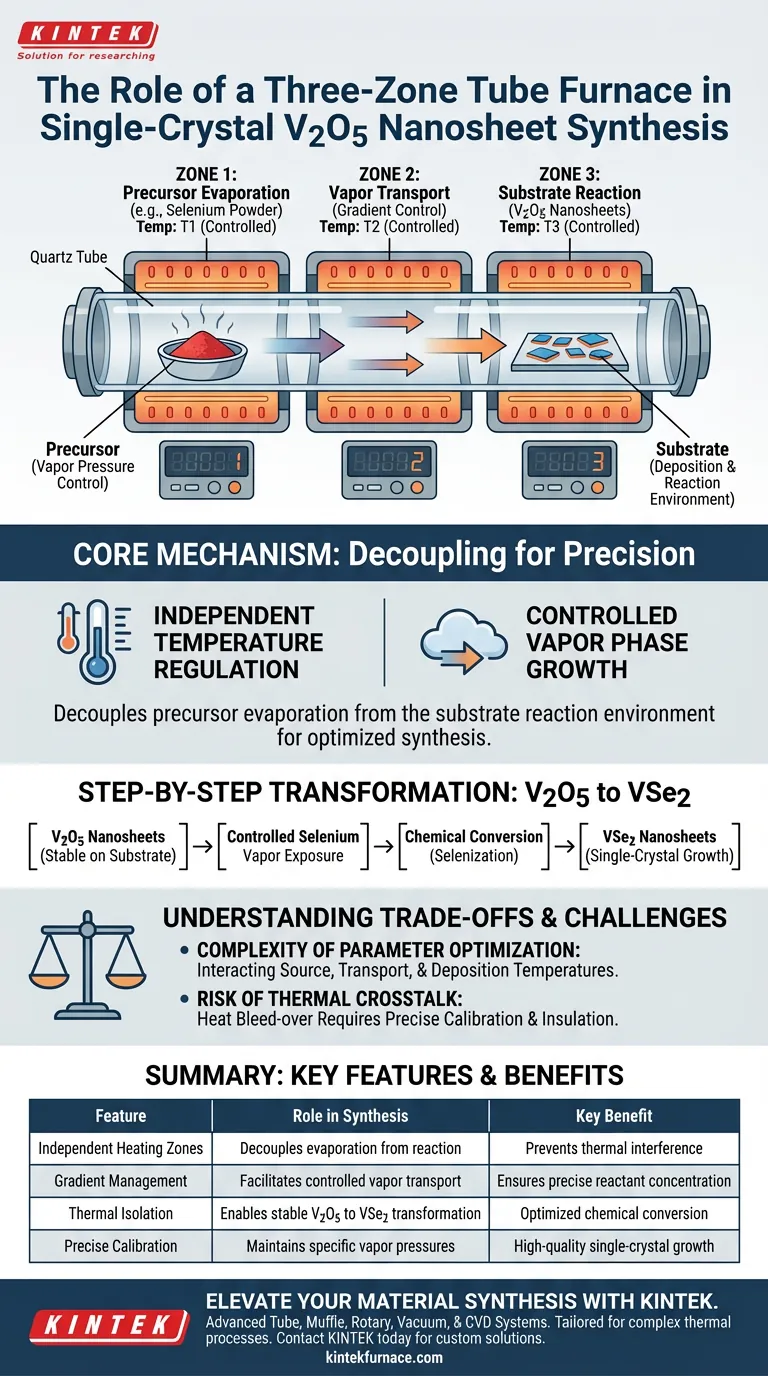

The Mechanism of Independent Control

Decoupling Precursor and Substrate

The defining feature of a three-zone furnace is its ability to isolate thermal variables.

You can set a specific temperature in the first zone to control the vapor pressure of a solid precursor, such as selenium powder.

Simultaneously, a downstream zone can be set to a completely different temperature to optimize the condition of the substrate (the V2O5 nanosheets).

Facilitating Vapor Transport

This thermal separation creates a controlled gradient.

The furnace ensures that the precursor vaporizes at a precise rate and travels downstream without condensing prematurely.

This transport mechanism is essential for bringing reactants to the substrate at the correct concentration.

The Goal: Step-by-Step Transformation

Enabling Chemical Conversion

In the context of V2O5 processing, this equipment is critical for achieving a step-by-step transformation.

The reference highlights the conversion from V2O5 to VSe2 as a primary application.

The furnace allows the V2O5 to remain stable while being exposed to the controlled selenium vapor, facilitating the chemical reaction (selenization) required for this transformation.

Precise Physical Prerequisites

Standard single-zone furnaces cannot support this complex synthesis.

Without independent zones, raising the temperature to heat the substrate would inadvertently alter the vaporization rate of the precursor.

The multi-zone capability creates the physical prerequisite necessary to balance these competing thermal needs.

Understanding the Trade-offs

Complexity of Parameter Optimization

While three-zone furnaces offer superior control, they introduce higher complexity in process optimization.

You must determine not just one reaction temperature, but the interaction between the source temperature, the transport zone, and the deposition zone.

The Risk of Thermal Crosstalk

A common pitfall is assuming total isolation between zones.

Heat from a high-temperature zone can bleed into adjacent zones, potentially destabilizing the vapor pressure of sensitive precursors.

Precise calibration and thermal insulation between zones are required to ensure the "independent" regulation remains effective.

Making the Right Choice for Your Goal

Depending on the specific phase of your synthesis or transformation process, focus on the following:

- If your primary focus is Precursor Management: Prioritize the calibration of the first zone to strictly control vapor pressure without degrading the source material.

- If your primary focus is Phase Transformation (e.g., V2O5 to VSe2): Focus on the downstream zones to ensure the substrate temperature is high enough to activate the reaction but low enough to prevent thermal decomposition.

Ultimately, the three-zone furnace is not just a heater; it is a flow controller that uses temperature to dictate the precise movement and reaction of matter.

Summary Table:

| Feature | Role in V2O5 Synthesis | Key Benefit |

|---|---|---|

| Independent Heating Zones | Decouples precursor evaporation from substrate reaction | Prevents thermal interference |

| Gradient Management | Facilitates controlled vapor transport | Ensures precise reactant concentration |

| Thermal Isolation | Enables stable V2O5 to VSe2 transformation | Optimized chemical conversion |

| Precise Calibration | Maintains specific vapor pressures | High-quality single-crystal growth |

Elevate Your Material Synthesis with KINTEK

Precision is the foundation of high-quality single-crystal synthesis. Backed by expert R&D and world-class manufacturing, KINTEK provides advanced Tube, Muffle, Rotary, Vacuum, and CVD systems tailored for complex thermal processes. Whether you are performing delicate selenization of V2O5 or advanced vapor phase deposition, our customizable high-temperature furnaces deliver the independent zone control and thermal stability your research demands.

Ready to optimize your laboratory's synthesis capabilities? Contact KINTEK today to discuss your unique needs with our technical specialists.

Visual Guide

References

- Gangtae Jin. Controlled Vapor-Phase Synthesis of VSe2 via Selenium-Driven Gradual Transformation of Single-Crystalline V2O5 Nanosheets. DOI: 10.3390/nano15070548

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the significance of a multi-zone configuration in a horizontal tube furnace? Master FC-CVD Synthesis Control

- How does a high-precision tube furnace influence the growth quality of graphene? Optimize CVD Synthesis Performance

- Why is annealing in a tube furnace essential for rGO-NiO-ZnO-400? Optimize Your Catalyst Synthesis

- How do the heating elements in a tube furnace function? Uncover Key Insights for Precise Heating

- What role does a dual porcelain boat layout play within a tube furnace? Enhance Ni-N-C Selenization with Spatial Control

- What role does a high-temperature tube furnace play in Silicon/Hard Carbon synthesis? Master Battery Anode Production

- What are the space and footprint considerations for vertical and horizontal tube furnaces? Optimize Your Lab Layout

- What are the applications of fluidized bed vertical tube furnaces? Achieve Uniform Heating for Powdered Materials