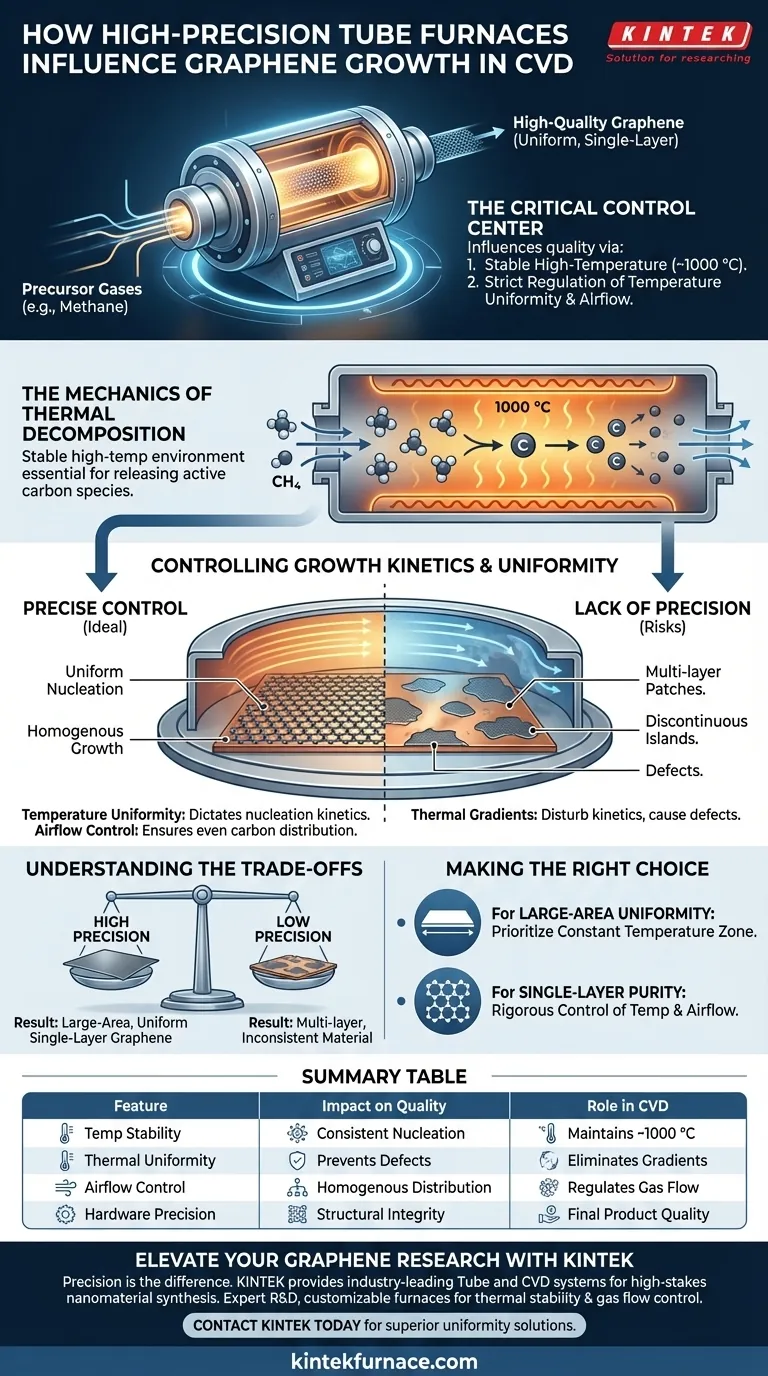

The high-precision tube furnace acts as the critical control center for graphene synthesis. It influences growth quality by maintaining a rigorous high-temperature environment, typically around 1000 °C, which is essential for the thermal decomposition of precursor gases like methane. By strictly regulating temperature uniformity and airflow, the furnace governs the reaction kinetics on metal catalysts, directly determining whether the resulting graphene is a uniform, single-layer sheet or an inconsistent material.

In Chemical Vapor Deposition (CVD), the tube furnace is not merely a heating element; it provides the precise thermodynamic stability required to control carbon atom nucleation. This hardware is the deciding factor in achieving large-area, highly uniform single-layer graphene.

The Mechanics of Thermal Decomposition

Creating the Reaction Environment

To synthesize graphene, precursor gases such as methane must be thermally decomposed to release active carbon species.

This process requires a stable high-temperature environment, generally sustained at approximately 1000 °C.

Stability and Consistency

A high-precision furnace ensures that this temperature remains constant throughout the process.

Without this thermal stability, the decomposition rate of the precursor gas would fluctuate, leading to unpredictable availability of carbon atoms.

Controlling Growth Kinetics and Uniformity

The Role of Temperature Uniformity

The primary reference highlights that temperature uniformity within the furnace chamber is vital for quality control.

This uniformity directly dictates the kinetics of how carbon atoms nucleate and grow on metal catalytic substrates, such as copper or nickel foils.

Managing Nucleation Rates

Precise thermal control allows for a regulated rate of nucleation.

When kinetics are managed correctly, carbon atoms arrange themselves into the desired lattice structure rather than clumping or forming defects.

Airflow Control

In addition to thermal regulation, the tube furnace creates specific airflow conditions within the chamber.

Proper control of gas flow ensures that the carbon source is evenly distributed across the catalytic substrate, facilitating homogenous growth.

Understanding the Trade-offs

Sensitivity to Thermal Gradients

The CVD process is unforgiving regarding temperature variations.

If a furnace lacks high precision, thermal gradients (hot or cold spots) can form within the chamber.

Impact on Layer Quality

These gradients disturb the kinetics of growth, often resulting in multi-layer patches or discontinuous islands of graphene.

Consequently, hardware that cannot maintain strict uniformity is generally unsuitable for manufacturing large-area, single-layer graphene.

Making the Right Choice for Your Goal

To maximize the quality of your graphene synthesis, align your hardware capabilities with your specific output requirements.

- If your primary focus is large-area uniformity: Prioritize a furnace with a verified constant temperature zone to ensure consistent growth kinetics across the entire substrate surface.

- If your primary focus is single-layer purity: rigorous control over both temperature and airflow is required to strictly limit carbon supply and prevent multi-layer formation.

The tube furnace is the core hardware that dictates the structural integrity and uniformity of the final graphene product.

Summary Table:

| Feature | Impact on Graphene Quality | Role in CVD System |

|---|---|---|

| Temperature Stability | Ensures consistent carbon atom nucleation | Maintains ~1000 °C for precursor decomposition |

| Thermal Uniformity | Prevents multi-layer patches and defects | Eliminates thermal gradients across the substrate |

| Airflow Control | Facilitates homogenous carbon distribution | Regulates gas flow for even reaction kinetics |

| Hardware Precision | Determines single-layer vs. multi-layer output | Governs the structural integrity of the final product |

Elevate Your Graphene Research with KINTEK

Precision is the difference between a defective material and a perfect single-layer lattice. KINTEK provides industry-leading Tube and CVD systems designed specifically for high-stakes nanomaterial synthesis. Backed by expert R&D and manufacturing, our customizable high-temperature furnaces deliver the thermal stability and gas flow control essential for consistent, large-area graphene growth.

Ready to achieve superior uniformity in your CVD process? Contact KINTEK today to consult with our experts on a solution tailored to your lab’s unique needs.

Visual Guide

References

- Fatemeh Saeedi, Mojtaba Haghgoo. Recent Advances of Graphene‐Based Wearable Sensors: Synthesis, Fabrication, Performance, and Application in Smart Device. DOI: 10.1002/admi.202500093

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the purpose of introducing high-purity nitrogen into a tube furnace? Optimize Bone Pyrolysis & Biochar Yield

- Why is it necessary to maintain a vacuum inside the tube? To Enable Controlled Electron Flow

- How is a tubular furnace utilized in the homogenization annealing of Ti-20Zr alloys? Precision Thermal Profiles

- How does a high-temperature tube furnace contribute to the post-deposition processing of Ge:ZnO thin films?

- What are the benefits of a horizontal tube furnace? Achieve Precise Thermal Control and Versatility

- Why is a nitrogen flow control system necessary for a tube furnace? Prevent Oxidation and Ensure Carbonization Yield

- What is the primary function of controlled thermal processing for YIG thin films? Unlock Magnetic Order in Spintronics

- What is the function of a vacuum tube furnace in NbC-Cr7C3@graphene/Fe synthesis? Expert Guide to In-Situ Synthesis