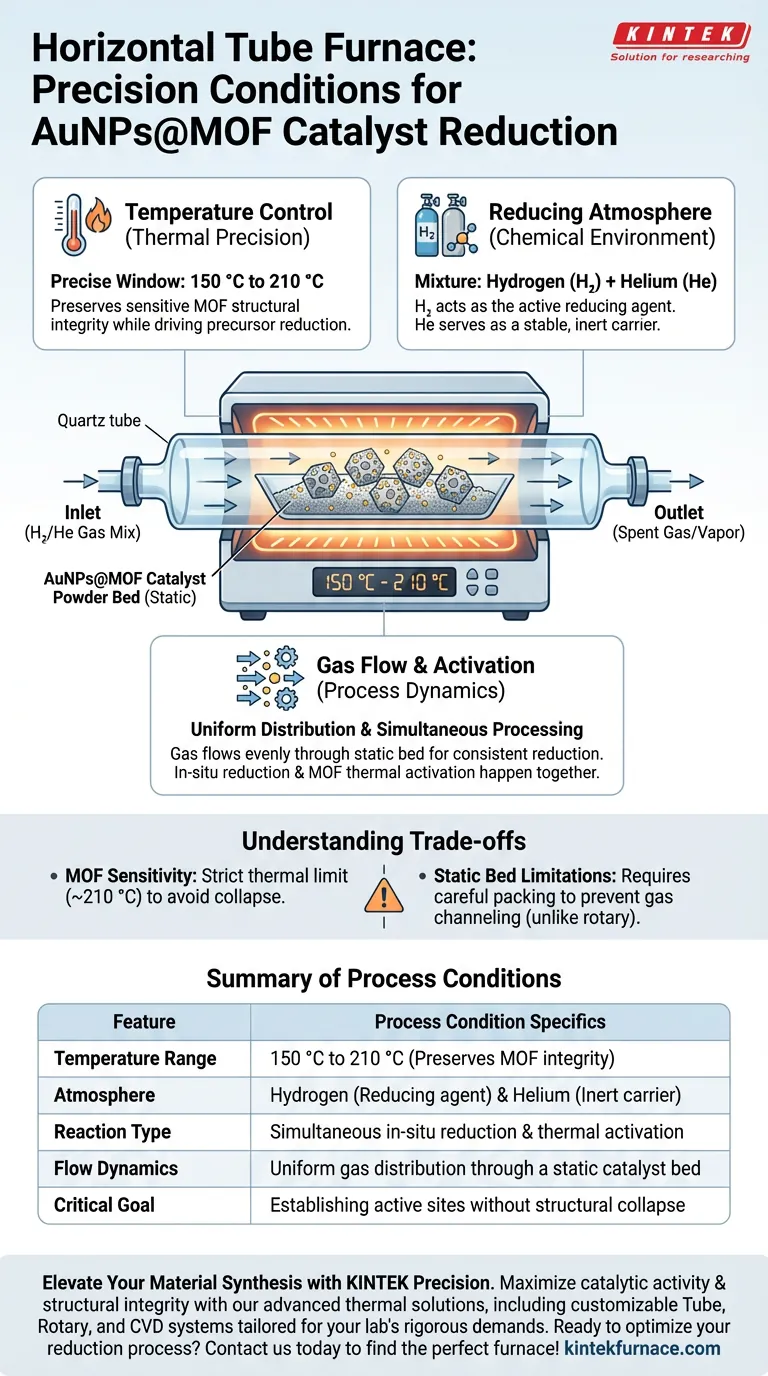

A horizontal tube furnace provides a strictly controlled thermal and chemical environment specifically tailored for the simultaneous reduction and activation of AuNPs@MOF catalysts. For this specific application, the process operates within a precise temperature window of 150 °C to 210 °C under a continuous flow of a hydrogen and helium gas mixture.

Core Insight: The horizontal tube furnace acts as a dual-function reactor. It does not simply heat the material; it creates a uniform flow field that synchronizes the in-situ reduction of gold precursors into nanoparticles with the thermal activation of the Metal-Organic Framework (MOF) support.

Thermal Precision and Atmosphere Control

Temperature Regulation

For AuNPs@MOF catalysts, the furnace maintains a relatively low-temperature environment, specifically between 150 °C and 210 °C.

This specific range is critical. It is high enough to drive the reduction of metal precursors but sufficiently low to preserve the structural integrity of the sensitive MOF support.

The Reducing Atmosphere

The process relies on a specific gas mixture composed of hydrogen and helium.

Hydrogen acts as the active reducing agent to convert precursors into metallic gold. Helium serves as an inert carrier gas, stabilizing the flow and ensuring the reducing agent is evenly distributed without unwanted side reactions.

Gas Flow and Structural Impact

Uniform Gas Distribution

A key function of the horizontal tube furnace is ensuring that the reduction gas flows uniformly through the catalyst powder bed.

Without this uniformity, gradients in the gas concentration could lead to uneven reduction. This would result in inconsistent catalytic properties across the batch.

Simultaneous Activation

The furnace environment allows for in-situ processing.

This means the reduction of gold nanoparticles (AuNPs) happens at the exact same time as the thermal activation of the MOF structure. This synchronization is essential for establishing the final active sites of the catalyst.

Understanding the Trade-offs

Sensitivity to Temperature Parameters

While tube furnaces offer high precision, the AuNPs@MOF synthesis is strictly bound by the thermal stability of the MOF.

Unlike oxide-supported catalysts that might withstand 700 °C (as seen in other reduction processes), MOFs can degrade if the furnace overshoots the 210 °C upper limit.

Static Bed Limitations

In a standard horizontal tube furnace, the powder bed is typically static.

While the gas flow is designed to be uniform, the lack of mechanical agitation (unlike a rotary furnace) means that the packing density of the powder must be carefully managed to prevent channeling, where gas bypasses sections of the catalyst.

Making the Right Choice for Your Goal

To maximize the efficacy of your AuNPs@MOF catalyst reduction, align your process parameters with your specific structural goals:

- If your primary focus is preserving MOF topology: Strictly cap your temperature at the lower end of the spectrum (closer to 150 °C) to minimize the risk of thermal collapse while accepting a slower reduction rate.

- If your primary focus is maximizing catalytic activity: Ensure the hydrogen/helium flow rate is optimized to penetrate the entire powder bed, preventing "dead zones" where precursors remain unreduced.

Precision in thermal and flow control is the deciding factor between a heterogeneous mixture and a high-performance catalyst.

Summary Table:

| Feature | Process Condition Specifics |

|---|---|

| Temperature Range | 150 °C to 210 °C (Preserves MOF integrity) |

| Atmosphere | Hydrogen (Reducing agent) & Helium (Inert carrier) |

| Reaction Type | Simultaneous in-situ reduction and thermal activation |

| Flow Dynamics | Uniform gas distribution through a static catalyst bed |

| Critical Goal | Establishing active sites without structural collapse |

Elevate Your Material Synthesis with KINTEK Precision

Maximize the catalytic activity and structural integrity of your sensitive MOFs with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of your lab. Whether you need precise atmosphere control for hydrogen reduction or uniform heat distribution for high-temp processing, our equipment is tailored to your unique research needs.

Ready to optimize your reduction process? Contact us today to find the perfect furnace for your laboratory!

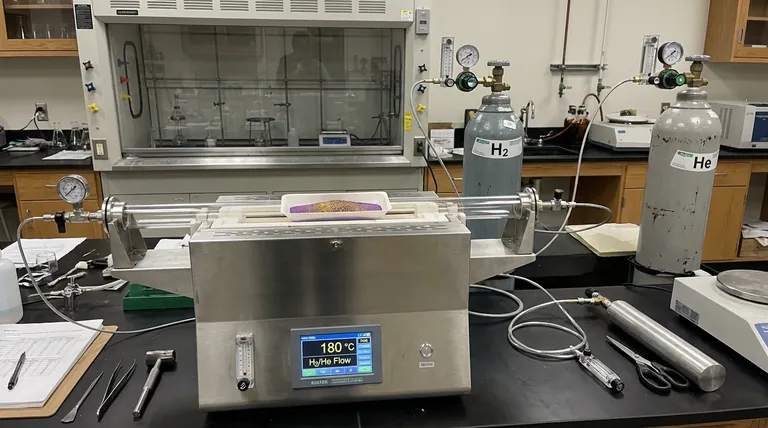

Visual Guide

References

- Simon Lukato, Grzegorz Litwinienko. Enhancing the Green Synthesis of Glycerol Carbonate: Carboxylation of Glycerol with CO2 Catalyzed by Metal Nanoparticles Encapsulated in Cerium Metal–Organic Frameworks. DOI: 10.3390/nano14080650

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What features contribute to the flexibility and diversity of a vertical tube furnace? Tailor Your Thermal Process

- What is the basic function of a High Temperature Tube Furnace? Precision Thermal Processing for Material Synthesis

- How does high-purity Nitrogen thermal annealing in a tube furnace facilitate the observation of Violet Phosphorus?

- What critical conditions do laboratory tube furnaces provide for VLS growth of ZnO nanowires? Master Nanoscale Synthesis

- Why is a high-temperature tube furnace with an Argon atmosphere required for the carbonization of biomass? Key Insights

- What is the specific function of a high-temperature tube furnace for MXene-NiCo2Se4? Master the Selenization Process

- What are the key heat treatment processes performed in horizontal furnaces? Master Annealing, Hardening, and More

- Why is a secondary high-temperature activation in a tubular furnace required? Unlock Peak Catalyst Performance