At its core, a high-temperature tube furnace is a precision tool for thermal processing. It is a specialized type of electric heater that uses heating coils wrapped around a cylindrical tube to create an extremely stable and uniform temperature environment. This controlled chamber is used across scientific research and industrial production to synthesize, purify, and test materials under precise thermal conditions.

The true value of a tube furnace is not simply its ability to reach high temperatures, but its capacity to create a precisely controlled, uniform, and often atmospheric-specific thermal environment. This level of control is what enables advanced material synthesis, purification, and process development.

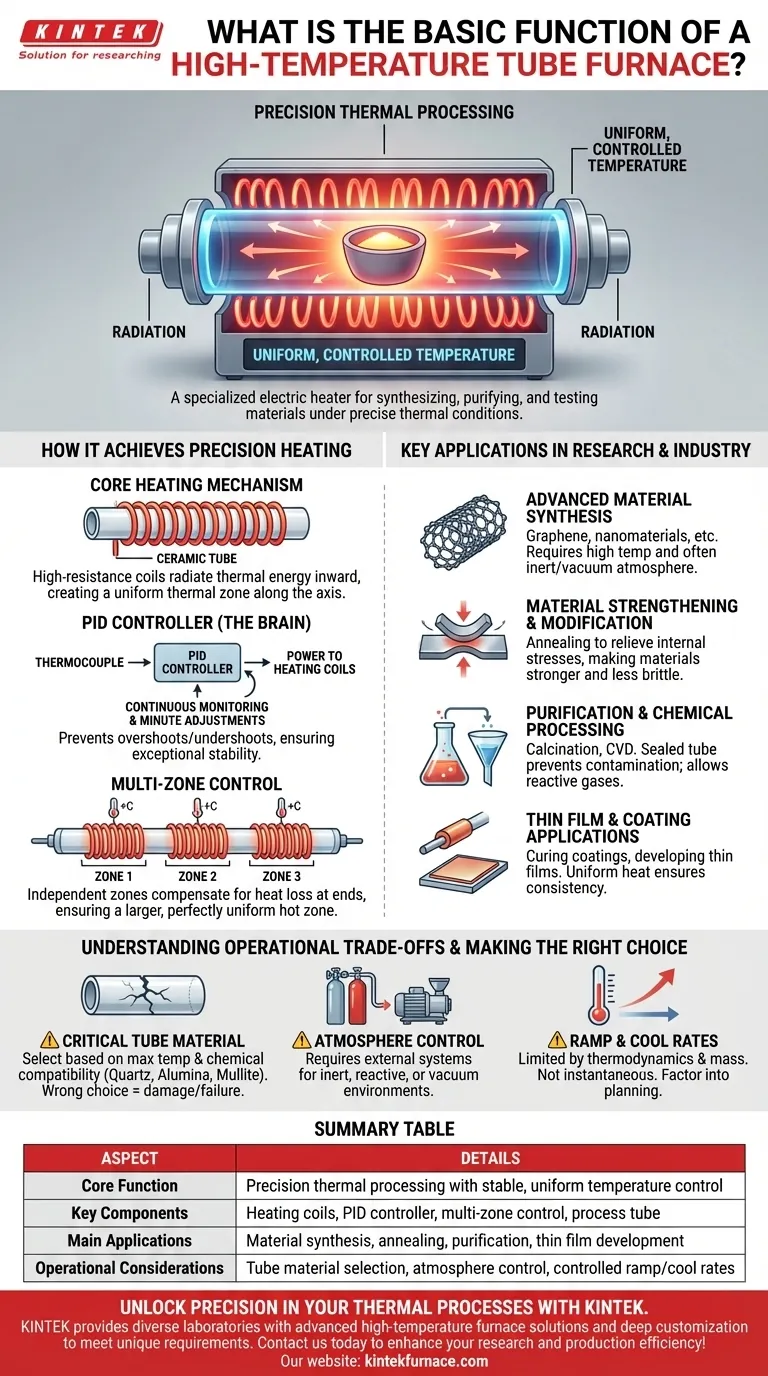

How a Tube Furnace Achieves Precision Heating

The effectiveness of a tube furnace comes from a synthesis of its heating elements and its intelligent control system. These components work together to deliver not just heat, but predictable and repeatable thermal profiles.

The Core Heating Mechanism

A tube furnace generates heat via high-resistance coils wrapped around a ceramic tube. When electricity passes through these coils, they heat up and radiate thermal energy inward, heating the process tube and any sample placed inside it.

The cylindrical design is intentional, as it helps concentrate this radiant energy to create a uniform thermal zone along the central axis of the tube.

The Role of the PID Controller

Temperature regulation is managed by an advanced PID (Proportional-Integral-Derivative) controller. Think of this as the furnace's brain.

It continuously monitors the temperature via a thermocouple and makes constant, minute adjustments to the power supplied to the heating coils. This prevents temperature overshoots and undershoots, ensuring the process temperature remains exceptionally stable.

Achieving Temperature Uniformity with Multi-Zone Control

While a single set of coils can heat a tube, more advanced furnaces feature multi-zone control. These models have several independent heating zones along the length of the tube.

Each zone has its own controller and thermocouple, allowing the system to compensate for natural heat loss at the ends of thetube. This ensures a much larger and more perfectly uniform hot zone, which is critical for consistent results with larger samples or longer processes.

Key Applications in Research and Industry

The precise control offered by tube furnaces makes them indispensable for a wide range of sophisticated applications.

Advanced Material Synthesis

Tube furnaces are central to creating next-generation materials like graphene, carbon nanotubes, and other nanomaterials. These processes often require not only high temperatures but also strictly controlled atmospheres (e.g., inert gas or vacuum), which the sealed tube environment facilitates.

Material Strengthening and Modification

Processes like annealing are used to relieve internal stresses in materials, making them stronger and less brittle. A tube furnace's ability to slowly ramp up to a specific temperature, hold it for a set duration, and then cool down at a controlled rate is essential for successful annealing.

Purification and Chemical Processing

In chemistry, tube furnaces are used to purify compounds or synthesize chemicals through processes like calcination or chemical vapor deposition (CVD). The sealed tube prevents contamination and allows for the introduction of specific reactive gases.

Thin Film and Coating Applications

The furnace provides the necessary thermal energy for curing coatings on wires or developing thin films on substrates. The uniform heat ensures the coating or film is consistent across the entire surface of the material being processed.

Understanding the Operational Trade-offs

While powerful, a tube furnace is a specialized instrument with operational considerations that must be respected to achieve desired results and ensure safety.

The Critical Choice of Tube Material

The process tube is not a one-size-fits-all component. The material of the tube—typically quartz, alumina, or mullite—dictates the maximum operating temperature and chemical compatibility. Using the wrong tube can lead to equipment damage, process failure, or sample contamination.

Atmosphere Control Requires External Systems

A tube furnace provides the sealed chamber, but it does not inherently create a vacuum or supply process gas. Achieving an inert, reactive, or vacuum environment requires connecting external vacuum pumps, gas lines, and flow controllers. The furnace simply facilitates the environment you create.

Ramp Rates and Cooling Are Not Instantaneous

The terms "rapid ramp rate" and "programmable cooling" are relative. Heating and cooling a dense ceramic chamber takes time. While programmable, these rates are limited by the laws of thermodynamics and the mass of the furnace components. This must be factored into process planning.

Making the Right Choice for Your Goal

Selecting and using a tube furnace effectively depends entirely on understanding your primary objective.

- If your primary focus is material synthesis (e.g., nanomaterials): Prioritize a furnace with excellent multi-zone control and robust ports for vacuum and gas handling to ensure process repeatability.

- If your primary focus is general heat treatment (e.g., annealing): A furnace with a large, guaranteed uniform hot zone and simple, reliable temperature profile programming is most critical.

- If your primary focus is high-purity chemical processing: Ensure the furnace tube material is completely inert to your chemicals at process temperatures and that the system has leak-tight seals.

Ultimately, a tube furnace empowers you to precisely manage thermal energy, turning a fundamental force into a powerful tool for innovation.

Summary Table:

| Aspect | Details |

|---|---|

| Core Function | Precision thermal processing with stable, uniform temperature control |

| Key Components | Heating coils, PID controller, multi-zone control, process tube |

| Main Applications | Material synthesis (e.g., graphene), annealing, purification, thin film development |

| Operational Considerations | Tube material selection, atmosphere control via external systems, controlled ramp/cool rates |

Unlock Precision in Your Thermal Processes with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're synthesizing nanomaterials, annealing metals, or developing thin films, we deliver reliable, tailored solutions for superior results.

Contact us today to discuss how our furnaces can enhance your research and production efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab