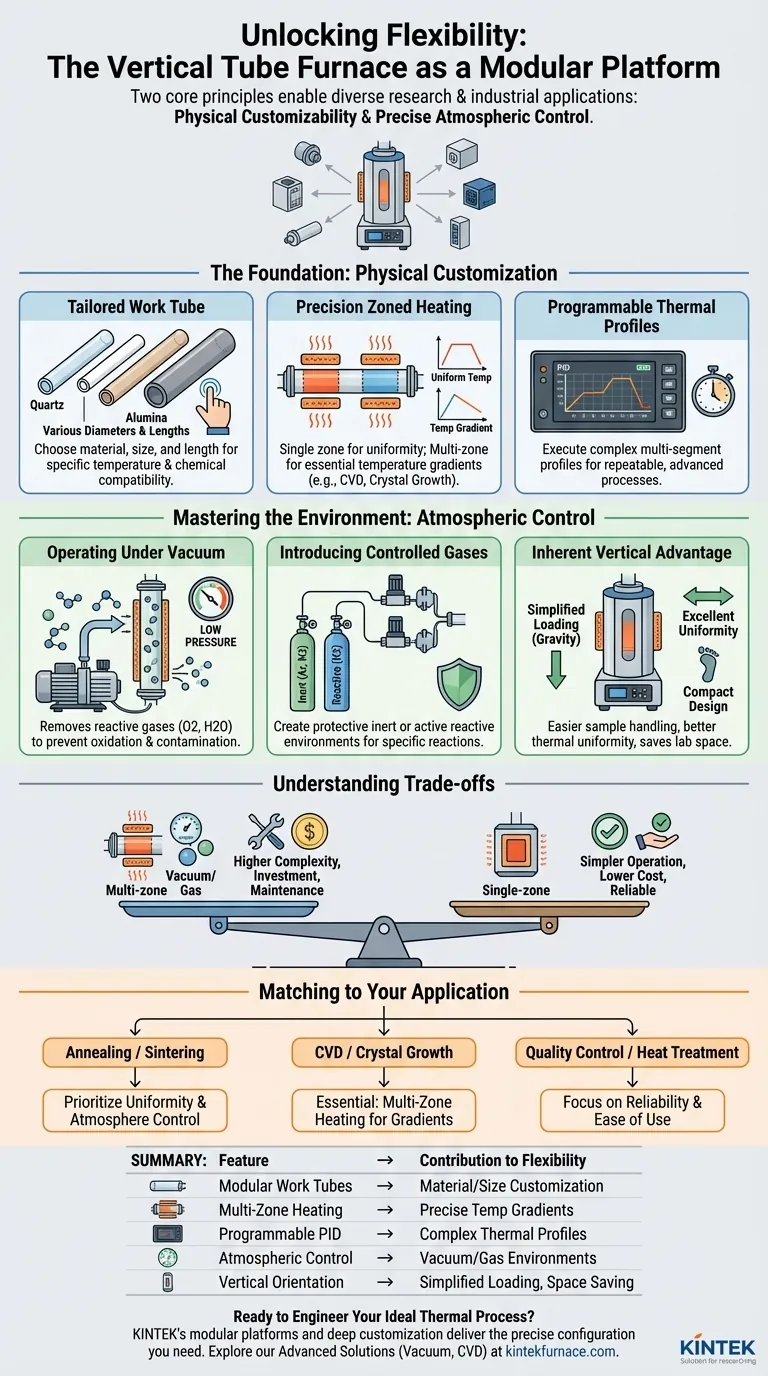

At its core, the flexibility of a vertical tube furnace comes from two fundamental principles: its high degree of physical customizability and its capacity for precise atmospheric control. These features allow it to be tailored from a general heating instrument into a highly specialized tool, capable of meeting the unique demands of diverse materials research, chemical experiments, and industrial heat treatment processes.

The true value of a vertical tube furnace is not that it's a single, fixed piece of equipment, but rather a modular platform. This design allows researchers and engineers to construct a specific, controlled thermal environment, rather than forcing their process to fit a pre-existing tool.

The Foundation of Flexibility: Modular Customization

A furnace's adaptability begins with its physical construction. The ability to specify key components ensures the equipment is perfectly matched to the process, rather than requiring compromises.

Tailoring the Work Tube

The central work tube is the heart of the furnace. The choice of its material (e.g., quartz, alumina), diameter, and length is the first layer of customization. This decision is driven by the required maximum temperature, chemical compatibility with the sample, and the physical size of the materials being processed.

Achieving Precision with Zoned Heating

Furnaces can be configured with a single heating zone for uniform temperature or with multiple, independently controlled heating zones. Multi-zone control is critical for advanced applications like crystal growth or chemical vapor deposition (CVD), where creating a specific temperature gradient along the length of the tube is essential for the process to succeed.

Programming Complex Thermal Profiles

Modern furnaces utilize advanced PID (Proportional-Integral-Derivative) controllers. These allow for multi-segment, multi-program storage, enabling users to execute complex thermal profiles with precise ramps, extended soaks at specific temperatures, and controlled cooling rates. This programmability is vital for achieving repeatable results.

Mastering the Environment: Atmospheric Control

Many advanced materials are highly sensitive to the atmosphere they are processed in. A vertical tube furnace provides the tools to define and maintain this crucial environment.

Operating Under Vacuum

The ability to connect a vacuum pump is a key feature. By pre-vacuuming the work tube, reactive atmospheric gases like oxygen and water vapor are removed. This is a non-negotiable step for preventing oxidation and contamination when working with sensitive metals and compounds.

Introducing Controlled Gases

Using gas-tight flange seals, a specific atmosphere can be introduced and maintained. This can be an inert gas like argon or nitrogen to provide a protective environment, or a reactive gas like hydrogen to participate in a specific chemical reaction. This capability transforms the furnace into a contained, controlled reactor.

The Inherent Vertical Advantage

The vertical orientation itself offers distinct benefits. It simplifies the loading and unloading of samples, especially for powders or crucible-based batch processing, by using gravity. This design also provides excellent temperature uniformity along the tube's length and typically has a compact footprint, saving valuable laboratory space.

Understanding the Trade-offs and Considerations

While flexibility is a significant advantage, it comes with practical implications that must be considered.

Complexity vs. Simplicity

A multi-zone furnace with an advanced gas handling and vacuum system is incredibly powerful. However, it also introduces a higher level of operational complexity, a steeper learning curve, and more potential points of failure compared to a basic, single-zone unit.

Performance and Energy Efficiency

The use of low thermal mass insulation allows for faster heat-up and cool-down cycles, increasing throughput. Efficient insulation and heat transfer mechanisms are also critical for minimizing energy consumption, which can be a significant operational cost.

Initial Investment and Maintenance

Increased customization directly impacts cost. A multi-zone furnace built with high-purity alumina tubes and a turbo-molecular vacuum pump is a far greater investment than a standard quartz tube model. Ongoing maintenance of seals, tubes, and vacuum systems is also a necessary operational reality.

Matching the Furnace to Your Application

Choosing the right configuration depends entirely on your end goal.

- If your primary focus is material annealing or sintering: Prioritize a system with excellent temperature uniformity and robust atmospheric control to ensure consistent material properties and prevent oxidation.

- If your primary focus is chemical vapor deposition (CVD) or crystal growth: A multi-zone heating configuration is essential for creating the precise temperature gradients that these sensitive processes demand.

- If your primary focus is routine quality control or general heat treatment: A simpler, single-zone furnace focused on reliability, ease of use, and repeatable thermal cycles will be the most efficient and cost-effective solution.

Ultimately, the power of a vertical tube furnace lies in its ability to be precisely engineered to meet the unique demands of your specific scientific or industrial process.

Summary Table:

| Key Feature | Contribution to Flexibility & Diversity |

|---|---|

| Modular Work Tubes | Customizable material (quartz, alumina), diameter, and length for specific temperature and chemical needs. |

| Multi-Zone Heating | Independently controlled zones enable precise temperature gradients for CVD, crystal growth, etc. |

| Programmable PID Control | Executes complex thermal profiles (ramps, soaks) for repeatable, advanced processes. |

| Atmospheric Control (Vacuum/Gas) | Enables inert, reactive, or vacuum environments to prevent oxidation or facilitate specific reactions. |

| Vertical Orientation | Simplifies sample loading/unloading, offers excellent temperature uniformity, and saves space. |

Ready to Engineer Your Ideal Thermal Process?

Your research and production demands are unique. Why settle for a standard furnace that forces compromises? KINTEK's vertical tube furnaces are built as modular platforms, leveraging our exceptional R&D and in-house manufacturing to deliver the precise configuration you need.

- Explore Our Advanced Solutions: From Muffle and Tube Furnaces to specialized Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, our product line is designed for diversity.

- Unlock Deep Customization: We go beyond standard options. Our strong customization capability tailors the furnace—from the work tube to the control system—to meet your exact experimental or industrial requirements.

Let's build the perfect tool for your application. Contact our experts today to discuss your specific needs and how we can provide a solution that enhances your flexibility, efficiency, and results.

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab

- What safety precautions should be followed when operating a multi zone tube furnace? Ensure Safe and Efficient Lab Operations

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials