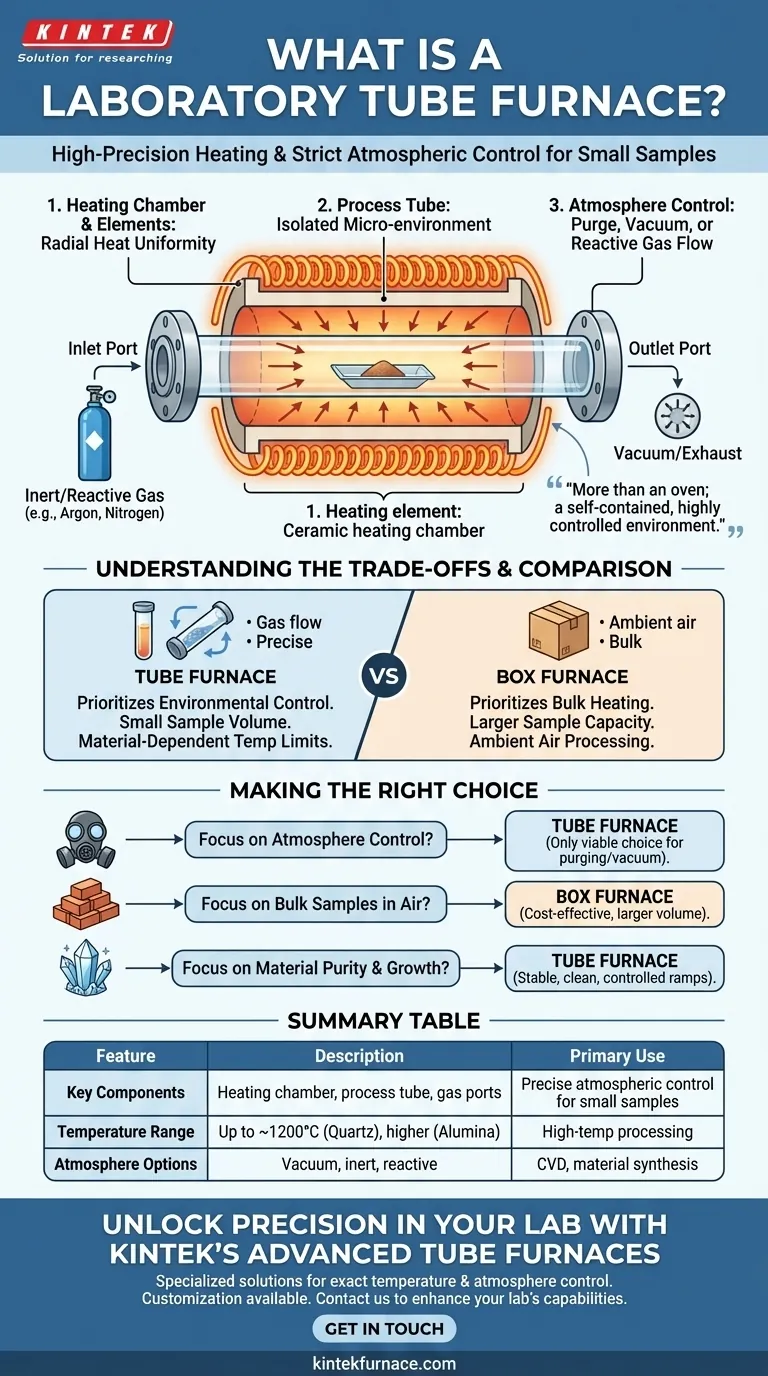

At its most fundamental level, a laboratory tube furnace is a high-temperature electric heating device designed for processing small samples with exceptional precision. It uses a cylindrical cavity to heat a separate "process tube" containing the material, allowing for not just uniform temperature but also strict control over the atmospheric environment.

A tube furnace is more than just an oven; it is a self-contained, highly controlled environment. Its primary value lies in its ability to isolate a sample from the ambient air, enabling thermal processing under vacuum or within a specific, engineered atmosphere.

How a Tube Furnace Achieves Precision Control

The design of a tube furnace is entirely centered on creating a stable and reproducible environment. This is accomplished through three key components working in concert.

The Heating Chamber and Elements

The outer body of the furnace contains resistive heating elements that surround a cylindrical ceramic chamber. This circular arrangement is critical for providing radial heat uniformity, ensuring the sample is heated evenly from all sides.

The Process Tube

The sample itself is never placed directly into the furnace's heating chamber. Instead, it is placed inside a separate, often transparent, process tube made from materials like quartz, alumina, or sapphire. This tube is then inserted through the center of the heating chamber.

This design is the source of the furnace's power. It isolates the sample from the heating elements and the outside world, creating a contained micro-environment.

Atmosphere Control

The ends of the process tube can be sealed with flanges that have gas inlet and outlet ports. This allows a user to purge the tube with an inert gas like argon or nitrogen to prevent oxidation, or to introduce specific reactive gases for processes like chemical vapor deposition (CVD). This level of atmospheric control is impossible in a standard oven or box furnace.

Understanding the Trade-offs

While powerful, a tube furnace is a specialized tool. Understanding its limitations is key to using it effectively.

Tube Furnace vs. Box Furnace

The most common point of confusion is comparing a tube furnace to a box furnace. A box furnace is designed for heating larger or more numerous samples in ambient air. It is a workhorse for general-purpose heat treatment.

A tube furnace, by contrast, prioritizes environmental control over sample volume. It is chosen when the atmosphere around the sample is as important as the temperature.

Temperature and Material Limitations

The maximum achievable temperature is determined by both the heating elements and the material of the process tube. Quartz tubes are common and allow for visual monitoring, but typically cannot exceed ~1200°C. For higher temperatures, an opaque alumina tube is required.

Sample Size Constraints

By their nature, tube furnaces are limited to samples that can fit within the diameter of the process tube, which typically ranges from one to six inches. They are not suitable for bulk material processing.

Making the Right Choice for Your Goal

Selecting the correct heating instrument depends entirely on your experimental requirements.

- If your primary focus is atmosphere control: The tube furnace is your only viable choice, as it is specifically designed for purging, vacuum, or reactive gas flow.

- If your primary focus is heating bulk samples in air: A box furnace offers a larger internal volume and is a more cost-effective solution.

- If your primary focus is material purity and crystal growth: A tube furnace provides the stable, clean, and controlled heating and cooling ramps necessary for these sensitive processes.

Ultimately, choosing a tube furnace is a decision to prioritize precise environmental control over sheer heating capacity.

Summary Table:

| Feature | Description |

|---|---|

| Primary Use | High-temperature processing with precise atmospheric control for small samples |

| Key Components | Heating chamber, process tube (e.g., quartz, alumina), gas inlet/outlet ports |

| Temperature Range | Up to ~1200°C with quartz tubes; higher with alumina tubes |

| Sample Size | Limited to tube diameter (typically 1-6 inches) |

| Atmosphere Options | Vacuum, inert gases (argon, nitrogen), reactive gases for processes like CVD |

| Advantages | Radial heat uniformity, isolation from ambient air, reproducible environments |

| Limitations | Smaller sample capacity compared to box furnaces, material-dependent temperature limits |

Unlock Precision in Your Lab with KINTEK's Advanced Tube Furnaces

Are you working on experiments that demand exact temperature and atmosphere control? KINTEK specializes in high-temperature furnace solutions tailored for diverse laboratory needs. Our tube furnaces, part of a comprehensive product line including Muffle, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, are engineered for superior performance and reliability.

Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental requirements, ensuring optimal results for material synthesis, heat treatment, and more. Don't let equipment limitations hold back your research—contact us today to discuss how our solutions can enhance your lab's capabilities and drive innovation.

Get in touch with our experts now!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability