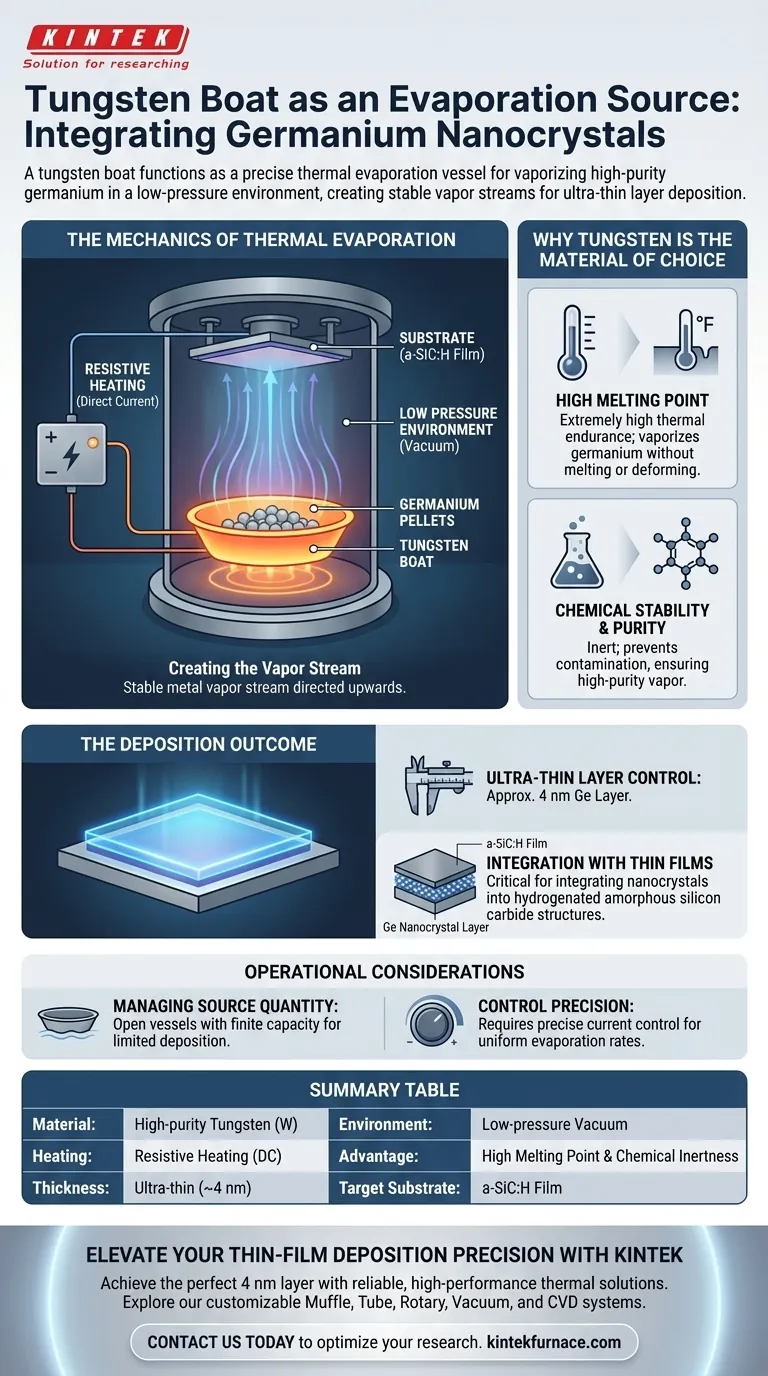

A tungsten boat functions as a precise thermal evaporation vessel designed to hold and vaporize high-purity germanium. By subjecting the boat to resistive heating within a low-pressure environment, it generates a stable stream of germanium vapor necessary for depositing ultra-thin layers onto substrate films.

The tungsten boat leverages its extreme melting point and chemical inertness to resistively heat germanium without contaminating the source material. This ensures the controlled deposition of ultra-thin (approx. 4 nm) layers essential for integrating nanocrystals into hydrogenated amorphous silicon carbide films.

The Mechanics of Thermal Evaporation

Resistive Heating Strategy

The tungsten boat serves as both the container and the heating element. An electrical current is passed directly through the tungsten, utilizing resistive heating to raise the temperature of the boat and the germanium it holds.

Vaporization in Low Pressure

The process occurs in a low-pressure environment (vacuum). This lowers the boiling point of the germanium and ensures the vaporized atoms travel in a straight line to the substrate without colliding with air molecules.

Creating the Vapor Stream

As the germanium heats up, it transitions into a vapor phase. The boat directs this stable metal vapor stream upwards toward the target surface, initiating the deposition process.

Why Tungsten is the Material of Choice

High Melting Point

Tungsten possesses an extremely high melting point, significantly higher than that of germanium. This thermal endurance allows the boat to reach the temperatures necessary to vaporize the germanium without melting or deforming itself.

Chemical Stability and Purity

Crucially, tungsten offers exceptional chemical stability. It does not react readily with the molten germanium, ensuring that the resulting vapor stream remains high-purity and free from tungsten contamination.

The Deposition Outcome

Ultra-Thin Layer Control

The stability provided by the tungsten boat allows for high-precision deposition. This method is capable of creating ultra-thin germanium layers, specifically around 4 nm in thickness.

Integration with Thin Films

This process is specifically engineered for depositing germanium onto hydrogenated amorphous silicon carbide (a-SiC:H) films. This layering is a critical step in the successful integration of germanium nanocrystals into the final structure.

Operational Considerations

Managing Source Quantity

Tungsten boats are open vessels with a finite capacity. They are best suited for processes requiring limited material deposition, such as the 4 nm layers described, rather than thick bulk coatings.

Control Precision

While resistive heating is effective, it requires precise current control. Fluctuations in the power supplied to the tungsten boat can lead to uneven evaporation rates, potentially affecting the uniformity of the nanocrystal integration.

Making the Right Choice for Your Goal

To ensure successful germanium integration, align your process controls with your specific objectives:

- If your primary focus is film purity: Prioritize the use of high-grade tungsten boats to prevent any chemical interaction or outgassing during the high-temperature phase.

- If your primary focus is layer thickness precision: Calibrate the resistive heating current meticulously to maintain a slow, steady evaporation rate for the target 4 nm thickness.

By utilizing the thermal and chemical resilience of a tungsten boat, you ensure the integrity of the germanium layer essential for high-performance nanocrystal structures.

Summary Table:

| Feature | Function in Ge Deposition |

|---|---|

| Material | High-purity Tungsten (W) |

| Heating Method | Resistive Heating (Direct Current) |

| Layer Thickness | Ultra-thin precision (approx. 4 nm) |

| Environment | Low-pressure vacuum for linear vapor stream |

| Key Advantage | High melting point & chemical inertness (no contamination) |

| Target Substrate | Hydrogenated amorphous silicon carbide (a-SiC:H) |

Elevate Your Thin-Film Deposition Precision with KINTEK

Achieving the perfect 4 nm germanium layer requires more than just a source; it requires reliable, high-performance thermal equipment. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing.

Whether you are integrating nanocrystals or developing complex thin-film structures, our Muffle, Tube, Rotary, Vacuum, and CVD systems are fully customizable to meet your unique laboratory needs.

Ready to optimize your research? Contact us today to discover how KINTEK’s specialized high-temperature furnaces and deposition tools can enhance your laboratory's efficiency and material purity.

Visual Guide

References

- Z. Remeš, Oleg Babčenko. Thin Hydrogenated Amorphous Silicon Carbide Layers with Embedded Ge Nanocrystals. DOI: 10.3390/nano15030176

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the role of a B-type thermocouple in aluminum alloy impurity evaporation? Master High-Precision Thermal Control

- What are the components of a tubular heater? Discover Key Parts for Efficient Industrial Heating

- What are the advantages of U-shaped heating elements (SIC Rods)? Unlock Installation Ease and High-Temp Performance

- What is the process by which a heating element converts electrical energy into heat? Discover Joule Heating Essentials

- What are the main advantages of ceramic infrared heaters? Achieve Instant, Efficient Heating for Your Space

- How do the linear expansion coefficient, thermal conductivity, and specific heat of silicon carbide elements vary with temperature? Essential Insights for High-Temp Design

- What temperature range can SIC heating elements operate at? Unlock High-Temp Efficiency Up to 1600°C

- In which industries are MoSi2 heating elements commonly used? Essential for High-Temp Glass, Ceramics, and More