In short, Molybdenum Disilicide (MoSi2) heating elements are predominantly used in industries requiring exceptionally high and precise process temperatures, typically above 1600°C. Their primary applications are found in glass production, ceramics manufacturing, metallurgy, and semiconductor fabrication, where conventional metallic elements would fail.

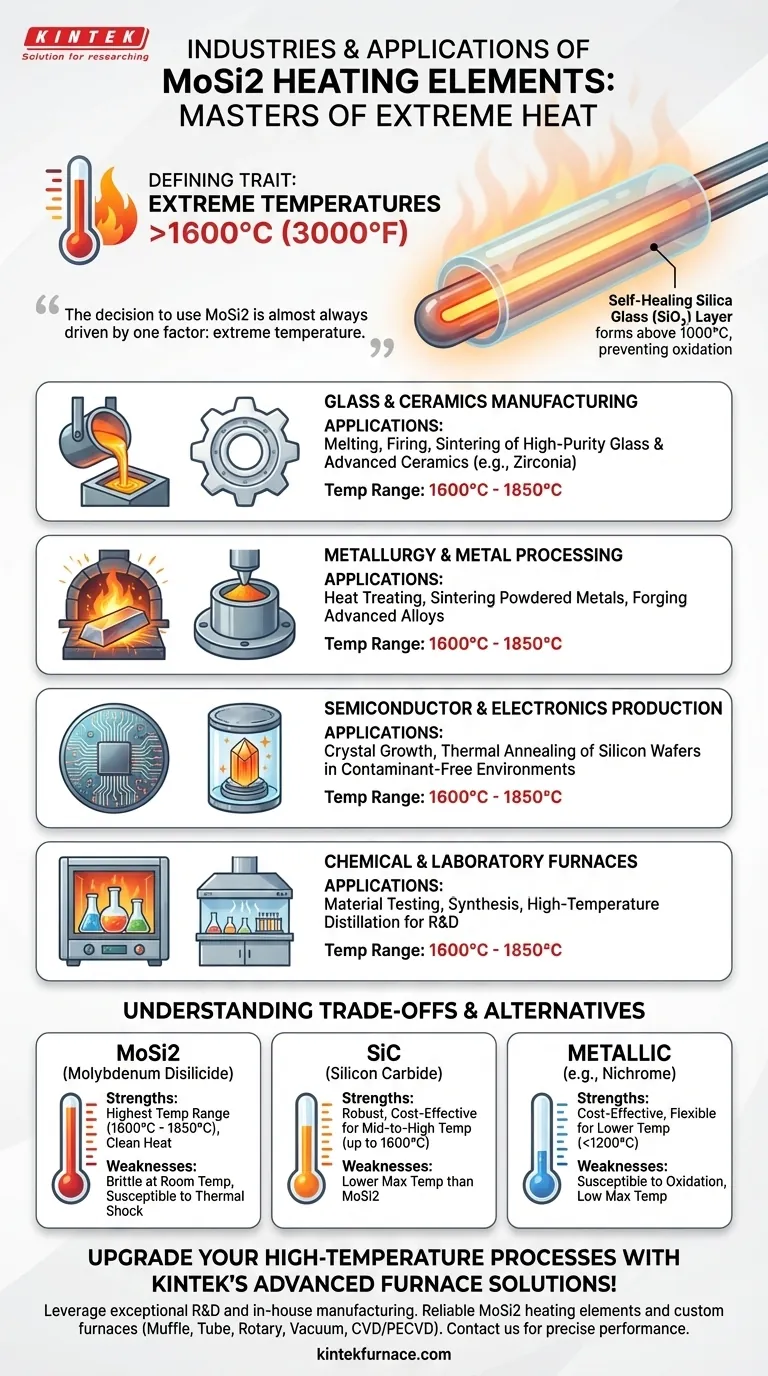

The decision to use a MoSi2 heating element is almost always driven by one factor: extreme temperature. While other elements are suitable for general heating, MoSi2 is the specialized tool for processes that operate in the highest temperature ranges, from 1600°C to over 1800°C.

The Defining Trait: Extreme Temperature Operation

MoSi2 heating elements are not general-purpose heaters. They are a specific class of ceramic-based elements engineered for the most demanding thermal environments.

How MoSi2 Withstands the Heat

The element's capability stems from its material properties. At high temperatures (above 1000°C), a thin, protective layer of silica glass (SiO₂) forms on the element's surface.

This self-healing "glaze" is what prevents the underlying material from oxidizing and failing, allowing it to operate reliably in air at temperatures that would destroy metallic elements like Nichrome or even other ceramics like Silicon Carbide.

Core Industrial Applications of MoSi2

The use of MoSi2 is concentrated in industries where material transformation requires clean, uniform, and very high heat.

Glass and Ceramics Manufacturing

These industries rely on MoSi2 for melting, firing, and sintering processes. High-purity glass melting and the firing of advanced ceramics, such as zirconia, demand temperatures and atmospheric purity that MoSi2 elements provide.

Metallurgy and Metal Processing

In metallurgy, MoSi2 elements are used in high-temperature furnaces for heat treating, sintering powdered metals, and forging advanced alloys. Their ability to deliver consistent heat is critical for achieving a material's desired microstructural properties.

Semiconductor and Electronics Production

The manufacturing of semiconductors and electronic components involves processes like crystal growth and thermal annealing of silicon wafers. These require a pristine, contaminant-free environment at very high temperatures, making MoSi2 an ideal choice.

Chemical and Laboratory Furnaces

Research and development labs and specialized chemical plants use MoSi2-equipped furnaces for material testing, synthesis, and high-temperature distillation. The element's stability ensures repeatable and accurate experimental conditions.

Understanding the Trade-offs and Alternatives

Choosing a heating element is a technical compromise. While MoSi2 excels at high temperatures, it is not the right choice for every application.

MoSi2 vs. Silicon Carbide (SiC)

Silicon Carbide is another common ceramic heating element. SiC is a workhorse for mid-to-high temperatures (typically up to 1600°C), while MoSi2 is for the highest temperature range (1600°C to 1850°C). SiC is generally more mechanically robust and can be more cost-effective if the absolute highest temperatures are not required.

MoSi2 vs. Metallic Elements (e.g., Nichrome)

Metallic elements, most commonly Nichrome (an alloy of nickel and chromium), are used for lower temperature applications, typically below 1200°C. They are significantly less expensive but have a much lower maximum operating temperature and are more susceptible to oxidation.

The Key Limitation of MoSi2

The primary drawback of MoSi2 is its brittleness at room temperature. The elements are fragile and must be handled with extreme care during installation and maintenance. They are also susceptible to damage from rapid thermal cycling, especially at lower temperatures.

Making the Right Choice for Your Process

Your selection should be dictated by your specific thermal and atmospheric requirements.

- If your primary focus is extreme temperatures (>1600°C) and process purity: MoSi2 is the industry standard and often the only viable option.

- If your primary focus is robust, general-purpose heating up to 1600°C: Silicon Carbide (SiC) offers a more durable and often more economical solution.

- If your primary focus is cost-sensitive heating below 1200°C: A metallic element like Nichrome or Kanthal (FeCrAl) is the most practical choice.

Ultimately, matching the element's unique properties to your process requirements is the key to achieving efficient, reliable, and safe thermal operations.

Summary Table:

| Industry | Key Applications | Typical Temperature Range |

|---|---|---|

| Glass & Ceramics | Melting, firing, sintering | 1600°C - 1850°C |

| Metallurgy | Heat treating, sintering metals | 1600°C - 1850°C |

| Semiconductor | Crystal growth, wafer annealing | 1600°C - 1850°C |

| Chemical & Lab | Material testing, synthesis | 1600°C - 1850°C |

Upgrade your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable MoSi2 heating elements and custom high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization ensures precise performance for your unique experimental needs. Contact us today to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C