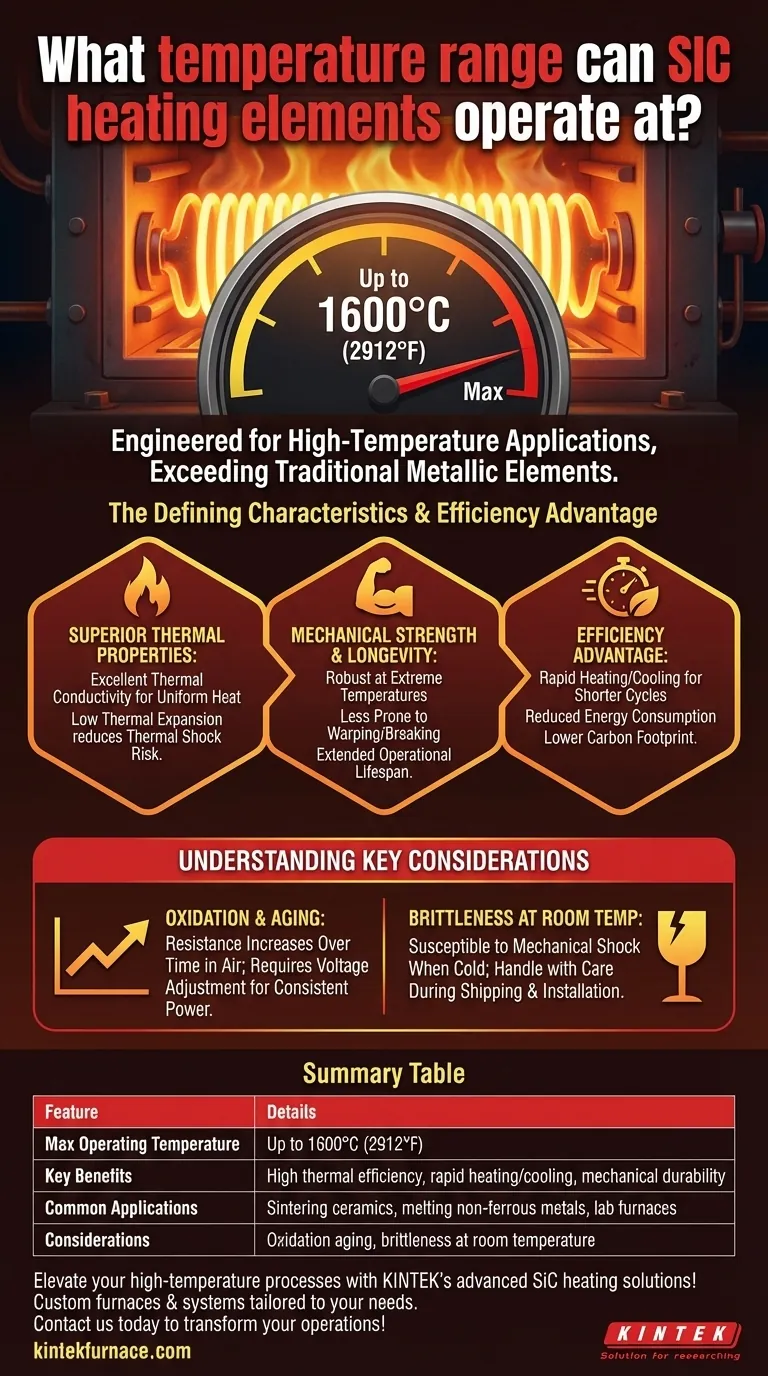

In short, Silicon Carbide (SiC) heating elements are engineered for high-temperature applications, capable of operating at surface temperatures up to 1600°C (2912°F). This capability significantly exceeds that of most traditional metallic heating elements, making them a default choice for demanding industrial processes.

While the high temperature ceiling is their most notable feature, the true value of SiC elements lies in their combination of thermal efficiency, rapid heating rates, and mechanical durability, which together lower operational costs and improve process reliability.

The Defining Characteristics of SiC Elements

Understanding why SiC elements are chosen requires looking beyond just their maximum temperature. Their physical and thermal properties work in concert to deliver superior performance in extreme environments.

Unlocking High-Temperature Processes

SiC elements reliably achieve and maintain temperatures that are inaccessible to many other materials. This makes them essential for processes that require consistent, intense heat.

Applications like sintering ceramics, melting non-ferrous metals, and various laboratory furnace operations depend on this high-temperature capability.

Superior Thermal Properties

SiC possesses excellent thermal conductivity. This ensures heat is transferred efficiently and evenly from the element to the furnace chamber, preventing hot spots and promoting uniform product quality.

Furthermore, these elements have a low coefficient of thermal expansion. They expand and contract very little when heated and cooled, which dramatically reduces the risk of thermal shock and mechanical breakage.

Mechanical Strength and Longevity

Even at extreme temperatures, SiC elements exhibit outstanding mechanical strength. This physical robustness makes them less prone to sagging, warping, or breaking compared to metallic alternatives.

This inherent durability translates directly into a longer operational lifespan, reducing the need for frequent replacements and minimizing costly maintenance downtime.

The Efficiency Advantage

The material properties of SiC also create significant advantages in energy use and process speed, directly impacting your bottom line.

Rapid Heating and Cooling

SiC elements can reach their target temperature very quickly. This rapid heating rate shortens process cycle times, increasing throughput.

The ability to cool down quickly also adds to process flexibility and can further reduce energy consumption between cycles.

Reduced Energy Consumption

The combination of efficient heat transfer and rapid heating means less energy is wasted. This leads to lower energy bills and a reduced carbon footprint for your operation.

By delivering heat precisely where and when it's needed, SiC elements contribute to more sustainable and cost-effective industrial heating.

Understanding the Key Considerations

While highly effective, SiC elements have operational characteristics that must be managed for optimal performance and longevity. They are not a universal drop-in replacement for all heating systems.

Oxidation and Element Aging

SiC elements are subject to oxidation, especially when operating in air at high temperatures. This process gradually increases the element's electrical resistance over time.

This "aging" is a normal and predictable characteristic. To maintain consistent power output, the power supply system must be capable of providing an increasing voltage over the element's service life.

Brittleness at Room Temperature

While very strong at high temperatures, SiC can be brittle and susceptible to mechanical shock when cold.

Care must be taken during shipping, handling, and installation to avoid fractures. Once installed and brought to temperature, their strength becomes a major asset.

Making the Right Choice for Your Goal

Selecting the right heating element depends entirely on the primary demands of your specific application.

- If your primary focus is reaching extreme temperatures: SiC is the definitive choice for processes requiring stable and reliable heat up to 1600°C.

- If your primary focus is process speed and throughput: The rapid heating and cooling cycles of SiC elements can significantly shorten process times and boost productivity.

- If your primary focus is long-term operational cost and reliability: The durability and energy efficiency of SiC elements reduce maintenance needs and lower energy bills over their extended lifespan.

Ultimately, choosing SiC heating elements is an investment in process capability, efficiency, and long-term reliability for high-demand thermal applications.

Summary Table:

| Feature | Details |

|---|---|

| Max Operating Temperature | Up to 1600°C (2912°F) |

| Key Benefits | High thermal efficiency, rapid heating/cooling, mechanical durability |

| Common Applications | Sintering ceramics, melting non-ferrous metals, lab furnaces |

| Considerations | Oxidation aging, brittleness at room temperature |

Elevate your high-temperature processes with KINTEK's advanced SiC heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with custom high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, boosting efficiency and reliability. Contact us today to discuss how our tailored solutions can transform your operations!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan